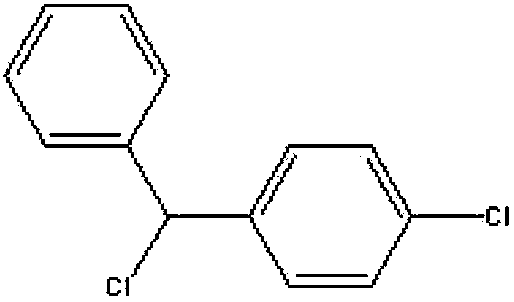

Method for preparing 4-dichlorodiphenylmethane

A technology of chlorobisphenyl chloride and chlorobenzophenone, which is applied in the field of preparing 4-chlorobisphenyl chloride, can solve the problems of easy combustion of hydrogen, cumbersome treatment process, high reaction temperature, etc., and achieve sufficient reaction and simple process , the effect of low reaction temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

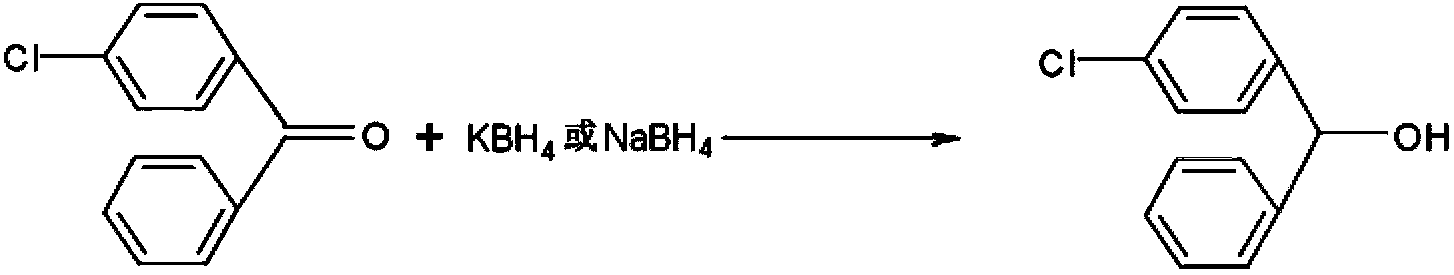

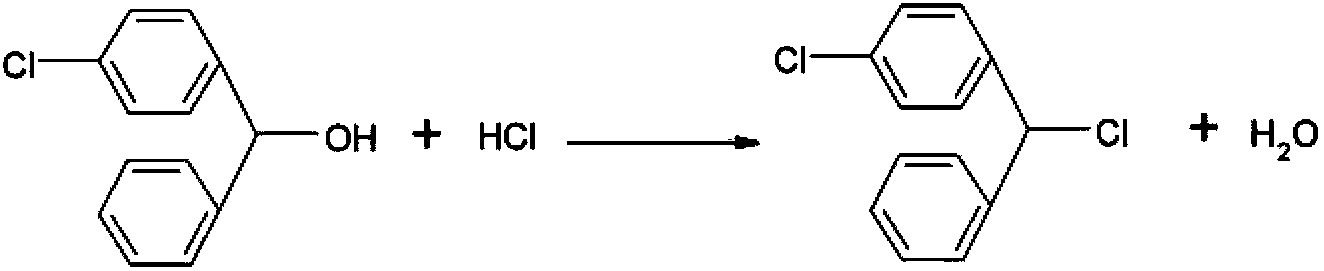

Method used

Image

Examples

Embodiment 1

[0059] Example 1: Add 350ml of absolute ethanol to a three-necked reaction flask, then add 150g of 4-chlorobenzophenone and 12g of potassium borohydride, stir and heat up, and react at about 80°C for 4 hours. After the reaction, the ethanol was distilled to obtain 4-chlorobenzhydryl alcohol. Then, 750 ml of 36% by mass hydrochloric acid aqueous solution was added and stirred to carry out chlorination reaction, and the reaction was carried out at about 77° C. for 4.5 hours. The reaction solution was cooled, and the organic layer was separated to obtain 147.8 g of 4-chlorodiphenylchloromethane. The conversion rate is 90%, and the content is 99.5%.

Embodiment 2

[0060] Example 2: Add 350ml of absolute ethanol to a three-necked reaction flask, then add 150g of 4-chlorobenzophenone and 22.5g of potassium borohydride, stir and heat up, and react at about 70°C for 3.5 hours. After the reaction, the ethanol was distilled to obtain 4-chlorobenzhydryl alcohol. Then, 700 ml of 36% by mass hydrochloric acid aqueous solution was added and stirred to carry out chlorination reaction, and the reaction was carried out at about 80° C. for 4 hours. The reaction solution was cooled, and the organic layer was separated to obtain 149.5 g of 4-chlorodiphenylchloromethane. The conversion rate is 91%, and the content is 99.7%.

Embodiment 3

[0061] Example 3: Add 350ml of absolute ethanol to a three-necked reaction flask, then add 150g of 4-chlorobenzophenone and 15g of potassium borohydride, stir and heat up, and react at about 77°C for 4.5 hours. After the reaction, the ethanol was distilled to obtain 4-chlorobenzhydryl alcohol. Then, 680 ml of 37% by mass hydrochloric acid aqueous solution was added and stirred for chlorination reaction, and the reaction was carried out at about 78° C. for 4.5 hours. The reaction solution was cooled, and the organic layer was separated to obtain 149.6 g of 4-chlorodiphenylchloromethane. The conversion rate is 91%, and the content is 99.5%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com