Preparation method of sucralose

A technology of sucralose and sucralose, which is applied in the preparation of sugar derivatives, chemical instruments and methods, sugar derivatives, etc., can solve the problems of affecting commercial application, long process flow of sucralose, complicated operation, etc., to avoid excessive Effects of chlorination and polymerization reactions, simplified operation steps, and improved reaction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

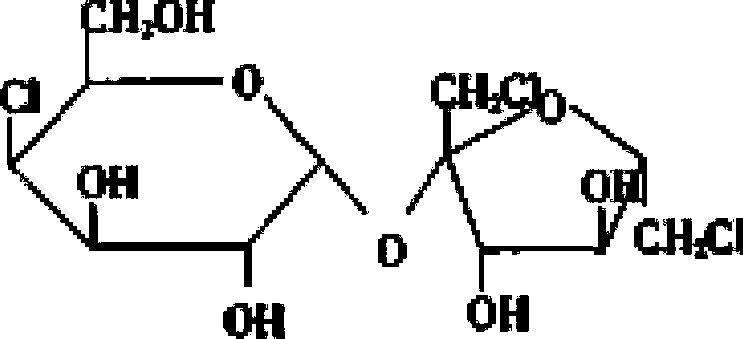

Image

Examples

Embodiment 1

[0020] The preparation method of sucralose comprises the steps:

[0021] (1) Put 150 grams of sucrose (342.3 grams per mole of sucrose) into N,N-dimethylformamide, then add toluenesulfonic acid and trimethyl orthoacetate, keep stirring at 30°C for 8 hours; add water, Stir at 25°C for 2 hours; add tert-butylamine and stir at 20°C for 2 hours; rectify under reduced pressure at 2mmHg and below 50°C to remove water and part of N,N-dimethylformamide to obtain 0.05% water Sucrose-6-acetate N, N-dimethylformamide solution, the mol ratio of described sucrose, N, N-dimethylformamide, toluenesulfonic acid, trimethyl orthoacetate, water, t-butylamine is: 1:22:0.02:1.5:8.0:0.4;

[0022] (2) At 0°C, add benzyltriethylammonium chloride (TEBA) to N,N-dimethylformamide, then add thionyl chloride, mix to obtain a mixture, and keep it warm for 2 hours; Next, add 2,6-di-tert-butyl-p-cresol (BHT) to the mixture, then add the solution obtained in step (1), and keep the reaction for 2 hours; heat...

Embodiment 2

[0025] The preparation method of sucralose comprises the steps:

[0026] (1) Put 150 grams of sucrose (342.3 grams per mole of sucrose) into N,N-dimethylformamide, then add toluenesulfonic acid and trimethyl orthoacetate, keep stirring at 20°C for 10 hours; add water, Stir at 20°C for 3 hours; add tert-butylamine and stir at 0°C for 3 hours; rectify under reduced pressure at 30mmHg and below 50°C to remove water and part of N,N-dimethylformamide, and obtain a water content of 0.12% Sucrose-6-acetate N, N-dimethylformamide solution, the mol ratio of said sucrose, N, N-dimethylformamide, toluenesulfonic acid, trimethyl orthoacetate, water, t-butylamine is : 1:20:0.03:1.5:5.0:0.5;

[0027] (2) At -15°C, add tetrabutylammonium bromide to N,N-dimethylformamide, then add thionyl chloride, mix to obtain a mixture, and keep it warm for 3 hours; Add 2,4,6-tri-tert-butylphenol to the mixture, then add the solution obtained in step (1), and keep it warm for 3 hours; heat up to 70°C, ke...

Embodiment 3

[0030] The preparation method of sucralose comprises the steps:

[0031] (1) Put 150 grams of sucrose (342.3 grams per mole of sucrose) into N,N-dimethylformamide, then add hydrogen chloride and triethyl orthoacetate, keep stirring at 35°C for 5 hours; Stir at ℃ for 1 hour; add tert-butylamine and stir at 30°C for 1 hour; rectify under reduced pressure at 20mmHg and below 50°C to remove water and part of N,N-dimethylformamide to obtain sucrose with a water content of 0.11% -6-Acetate N, N-dimethylformamide solution, the molar ratio of sucrose, N, N-dimethylformamide, hydrogen chloride, triethyl orthoacetate, water, t-butylamine is: 1:23 :0.015:2.0:8.0:0.2;

[0032](2) At -5°C, add tetrabutylammonium chloride to N,N-dimethylformamide, then add bis(trichloromethyl)carbonate, mix to obtain a mixture, and keep it warm for 2 hours; At 2°C, add tert-butylhydroquinone (TBHQ) to the mixture, then add the solution obtained in step (1), and keep the temperature for 2 hours; heat up to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com