Oil-soluble asphaltene dispersing blockage remover

A plugging remover, oil-soluble technology, applied in the field of oil-soluble asphaltene dispersion plugging remover, can solve the problems of crude oil composition change, fluorine or chlorine content, oil well shutdown or scrapping, etc., to prevent asphaltene precipitation, preparation process Simple and safe performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

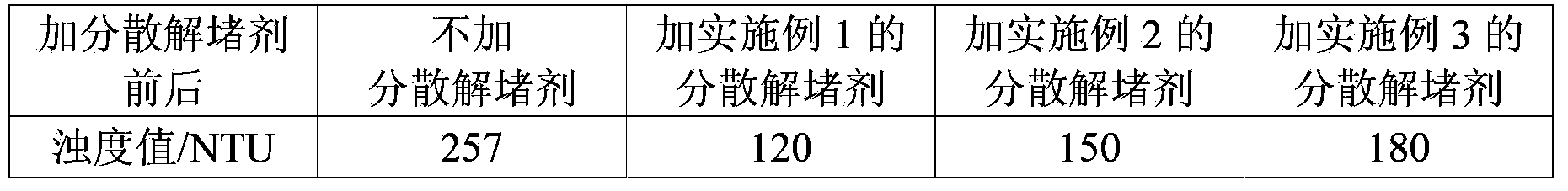

Embodiment 1

[0017] This embodiment provides an oil-soluble asphaltene dispersion plugging remover, based on the total weight of the dispersed plugging removal agent, its raw material composition includes: aromatic hydrocarbons: 10% benzene, toluene and xylene mixed in any proportion, ketone : Oxyphenone 45%, organic acid salt: CH 3 CH 2 CH(CH 3 ) 2 COONH 4 15%, mixed acrylate: CH 2 =CH-COOR (R is normal alkanes of C15 and C16) 12%, ionic surfactant: sodium dodecylbenzenesulfonate 10%, oil-soluble penetrant: 2-octyl alcohol polyoxyethylene ether (JFC) 8%; the oil-soluble asphaltene dispersion plugging agent is prepared by the following method: aromatic hydrocarbons, ketones, organic acid salts, acrylic acid mixed esters, ionic surfactants and oil-soluble penetrating agents are added to the reactor, and then 45 Stirring at a constant temperature of -85°C for 1-3 hours to obtain the oil-soluble asphaltene-dispersed plug-removing agent. The open flash point of the disperse plugging remo...

Embodiment 2

[0019] This embodiment provides an oil-soluble asphaltene dispersing plugging remover, based on the total weight of the dispersed plugging removing agent, its raw material composition includes: aromatics: 15% toluene, ketone: 40% phenyloctyl ketone, organic acid salts :CH 3 CH 2 CH 2 CH 2 CH 2 CH 2 COONH 4 15%, mixed acrylate: CH 2 =CH-COOR (R is C16-C18 normal alkanes) 10%, ionic surfactant: sodium dodecylbenzenesulfonate 10%, oil-soluble penetrant: lauryl polyoxyethylene ether (AEO) 10 %; The preparation method of the oil-soluble asphaltene dispersion plugging agent is the same as the preparation method in Example 1. The open flash point of the dispersed plug-removing agent was measured, and the results are shown in Table 1.

Embodiment 3

[0021] This embodiment provides an oil-soluble asphaltene dispersing plug-removing agent, based on the total weight of the dispersed plug-removing agent, its raw material composition includes: aromatic hydrocarbon: 15% xylene, ketone: 40% phenyloctylone, organic acid Salt: CH 3 CH 2 CH(CH 3 ) 2 COONH 4 15%, mixed acrylate: CH 2 =CH-COOR (R is C16-C18 n-paraffin) 8%, ionic surfactant: sodium dodecylbenzenesulfonate 15%, oil-soluble penetrating agent: isooctyl alcohol polyoxyethylene ether (JFC- E) 7%; the preparation method of this oil-soluble asphaltene dispersion plugging remover is the same as that in Example 1. The open flash point of the dispersed plug-removing agent was measured, and the results are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| flash point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com