Efficient saccharification processing method for maize straws

A technology for corn stalk and saccharification treatment, which is applied in the production of sugar, sugar production, glucose production, etc., can solve the problems of high equipment requirements, high energy consumption, low sugar yield, etc., and achieve high saccharification rate and reduce production energy. Consumption, simple operation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

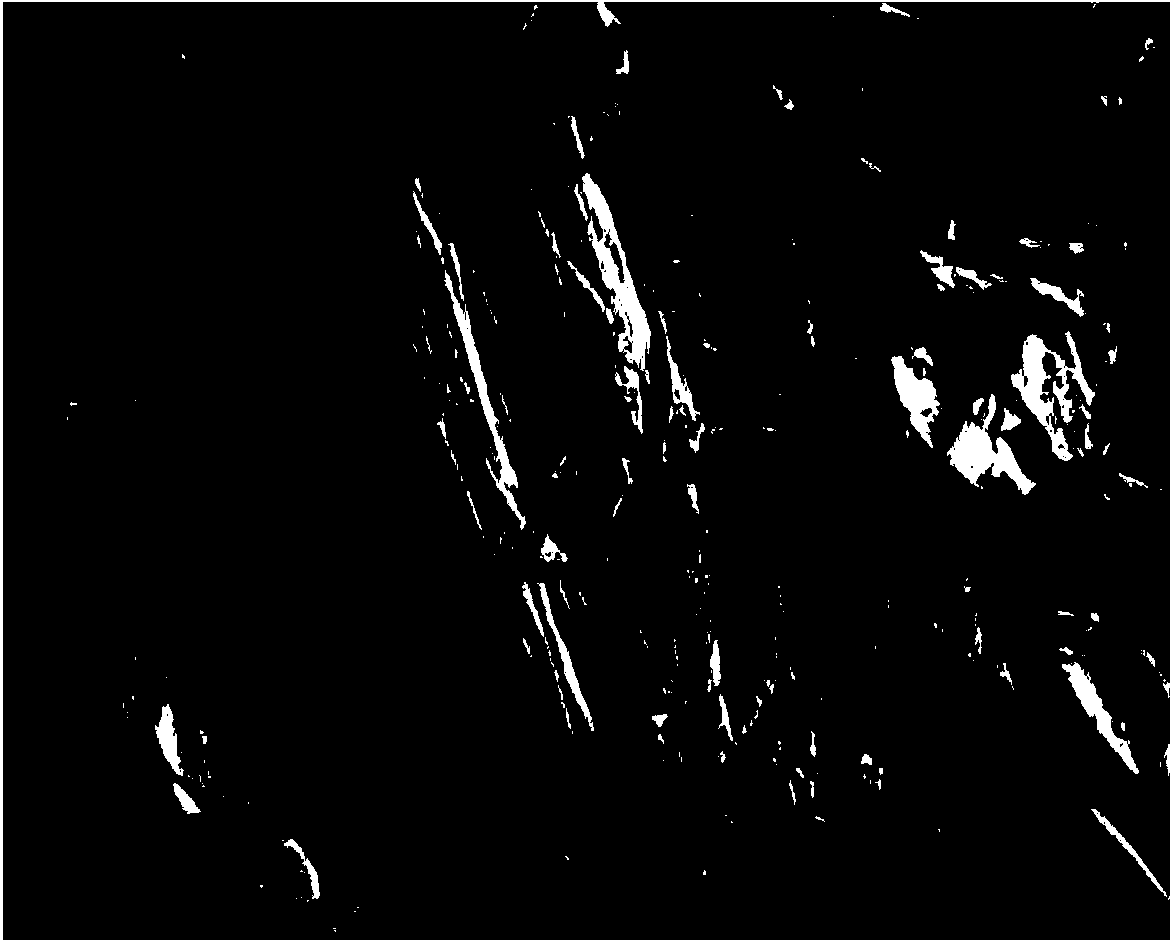

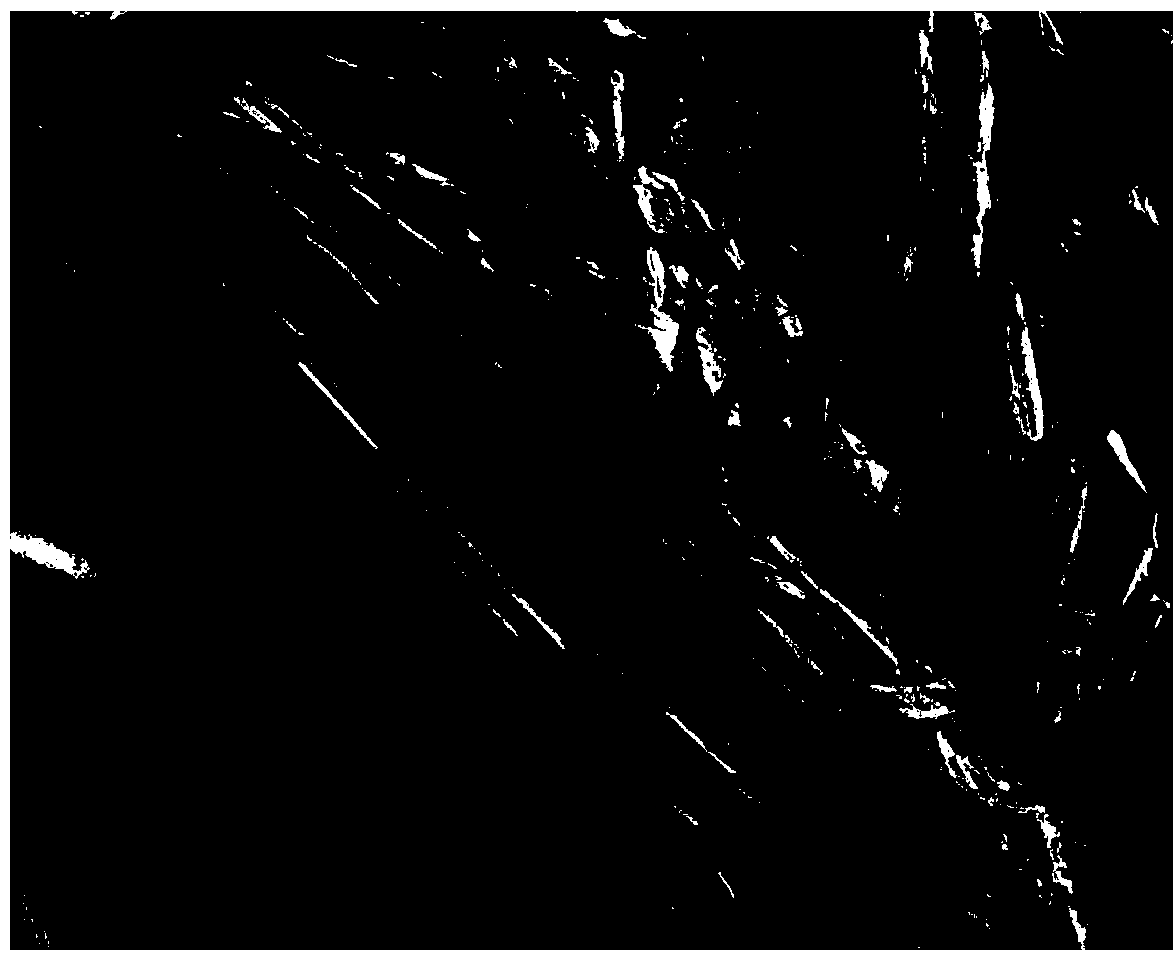

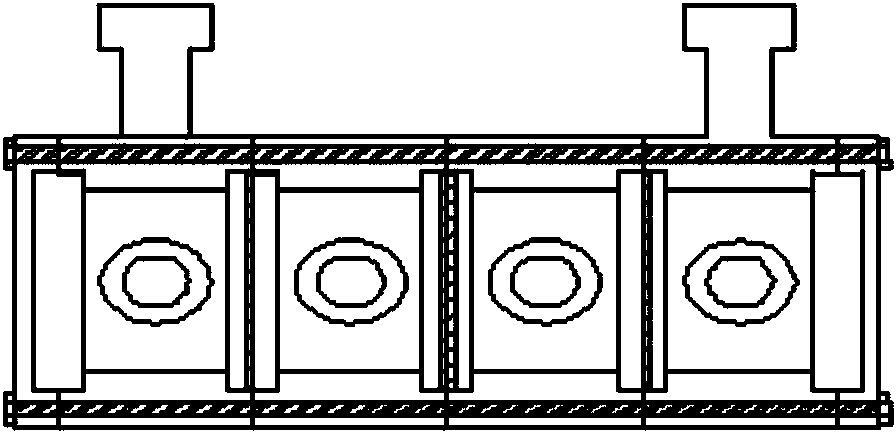

Image

Examples

specific Embodiment approach 1

[0049] Specific implementation mode 1: The method for high-efficiency saccharification treatment of corn stalks in this implementation mode is carried out according to the following steps:

[0050] 1. Crushing of corn stalk fiber raw materials:

[0051] Crush the dried corn stalks, pass through a 60-100 mesh sieve, and store at room temperature;

[0052] 2. Concentrated acid hydrolysis:

[0053] Mix the crushed raw materials in step 1 and the sulfuric acid solution with a mass percentage of 40% to 60% according to the ratio of mass to volume: 1g: (50 to 100) mL, let stand at room temperature for 20 to 40 minutes, and then Centrifuge at 5000r / min~10000r / min for 5min~10min, collect the centrifugate and concentrated acid hydrolysis residue respectively, wash the concentrated acid hydrolysis residue with water, mix the cleaning solution with the centrifugate to obtain a mixed solution;

[0054] 3. Acid recovery:

[0055] The mixed solution obtained in step 2 is separated from the...

specific Embodiment approach 2

[0058] Specific embodiment 2: The difference between this embodiment and specific embodiment 1 is that the raw material after step 1 crushing described in step 2 and the sulfuric acid solution with a mass percentage content of 60% are 1g: 50mL according to the mass-to-volume ratio ratio mix. Others are the same as in the first embodiment.

specific Embodiment approach 3

[0059] Embodiment 3: This embodiment differs from Embodiment 1 or Embodiment 2 in that it is centrifuged for 5 minutes at a rate of 5000 r / min as described in Step 2. Others are the same as in the first or second embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com