Preparation method of zno-in2o3 nano semiconductor crystal gas sensitive material

A nano-semiconductor, zno-in2o3 technology, applied in nanotechnology, nanotechnology, material resistance and other directions, can solve the problems of inability to significantly improve performance, poor gas sensitivity, long gas response time, etc., to achieve excellent sensitive performance, simple equipment, Good product stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

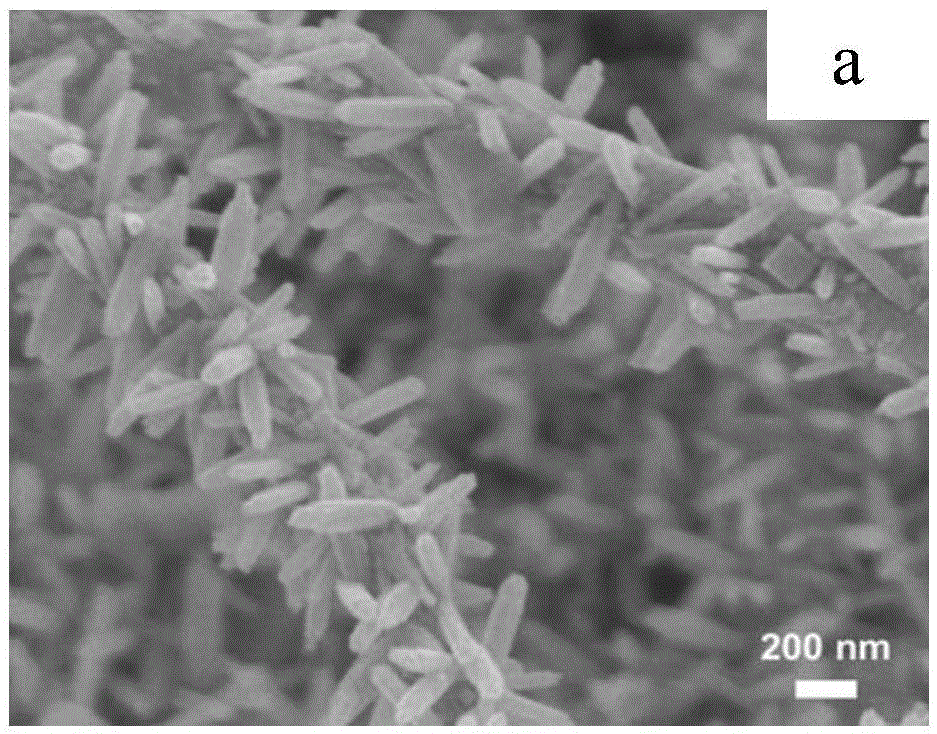

[0022] Example 1: Pine branched high ethanol sensitive performance ZnO-In 2 o 3 Preparation of nanocomposites;

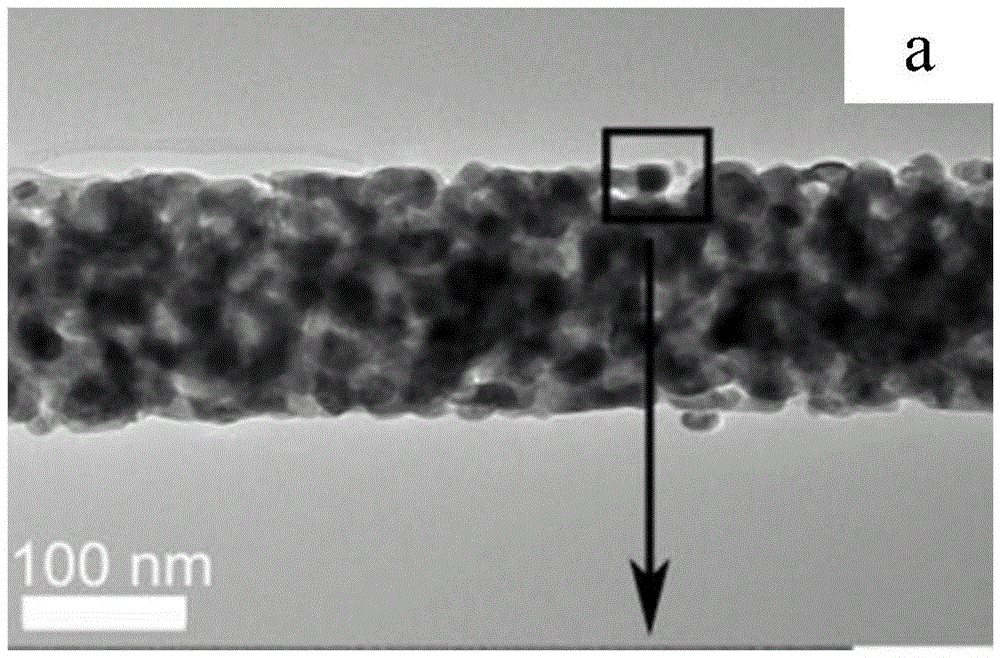

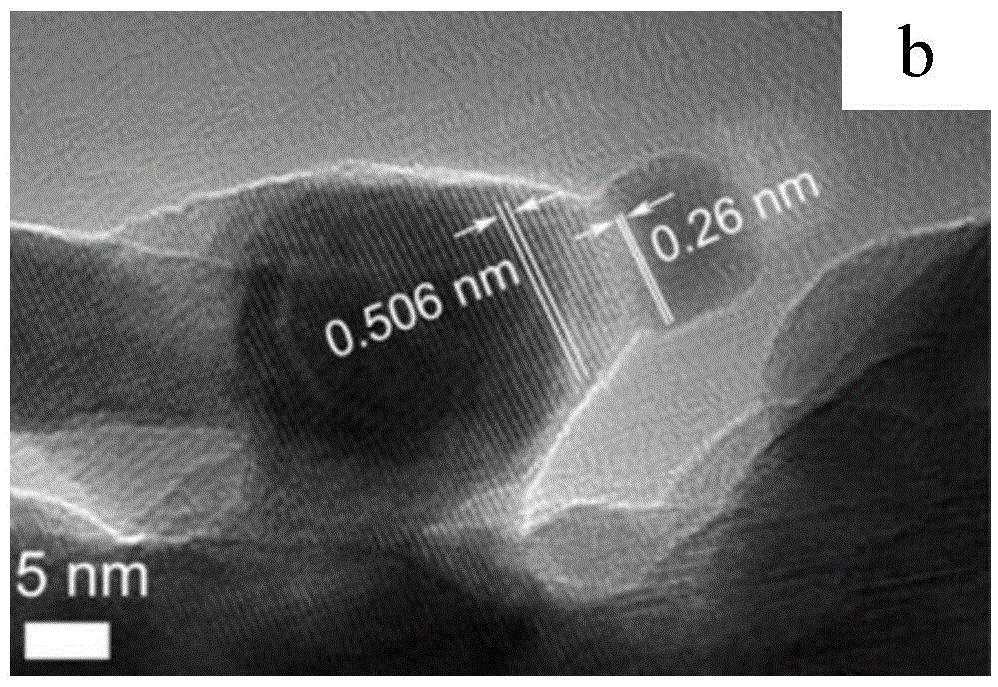

[0023] (1) Preparation of ZnO-In 2 o 3 composite nanofibers.

[0024] ZnO-In 2 o 3 The synthesis of composite nanofibers is improved according to the methods reported in the existing literature. The ethanol of 6.6g and the DMF of 2.2g are joined in the beaker of 25mL, stir can obtain mixed solvent, add the Zn(NO 3 ) 2 ·6H 2 O, 200mg of In(NO 3 ) 3 9 / 2H 2 O, and 800mg of Polyvinylpyrrolidone (PolyvinylpyrrolidonePVP), in which zinc nitrate and indium nitrate are used as zinc source and indium source respectively, and PVP can increase the viscosity of the solution on the one hand, and on the other hand, it is added as a skeleton support for spinning . Stir vigorously for 5 hours to obtain a uniform colorless and transparent precursor solution; use a 5mL medical syringe with a 22G spinning needle with an inner diameter of 0.41mm to hold the precursor solut...

Embodiment 2

[0027] Example 2: Pine branched high ethanol sensitive performance ZnO-In 2 o 3 Preparation of nanocomposites;

[0028] (1) Preparation of ZnO-In 2 o 3 composite nanofibers.

[0029] ZnO-In 2 o 3 The synthesis of composite nanofibers was modified from the reported method. The ethanol of 9.9g and the DMF of 3.3g are joined in the beaker of 25mL, stir can obtain mixed solvent, add the Zn of 300mg wherein (NO 3 ) 2 ·6H 2 O, In(NO 3 ) 3 9 / 2H 2 O, and 1200mg of Polyvinylpyrrolidone (PolyvinylpyrrolidonePVP), in which zinc nitrate and indium nitrate are used as zinc source and indium source respectively, and PVP can increase the viscosity of the solution on the one hand, and on the other hand, it is added as a skeleton support for spinning . Stir vigorously for 5 hours to obtain a uniform colorless and transparent precursor solution; use a 5mL medical syringe with a 22G spinning needle with an inner diameter of 0.41mm to hold the precursor solution for electrospinning, ...

Embodiment 3

[0032] Example 3: Pine branched high ethanol sensitive performance ZnO-In 2 o 3 Preparation of nanocomposites;

[0033] (1) Preparation of ZnO-In 2 o 3 composite nanofibers.

[0034] ZnO-In 2 o 3 The synthesis of composite nanofibers was modified from the reported method. The ethanol of 5.5g and the DMF of 1.83g are joined in the beaker of 25mL, stir can obtain mixed solvent, add the Zn(NO 3 ) 2 ·6H 2 O, In(NO 3 ) 3 9 / 2H 2 O, and 667mg of Polyvinylpyrrolidone (PolyvinylpyrrolidonePVP), in which zinc nitrate and indium nitrate are used as zinc source and indium source respectively, and PVP can increase the viscosity of the solution on the one hand, and on the other hand, it is added as a skeleton support for spinning . Stir vigorously for 5 hours to obtain a uniform colorless and transparent precursor solution; use a 5mL medical syringe with a 22G spinning needle with an inner diameter of 0.41mm to hold the precursor solution for electrospinning, where the DC volta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com