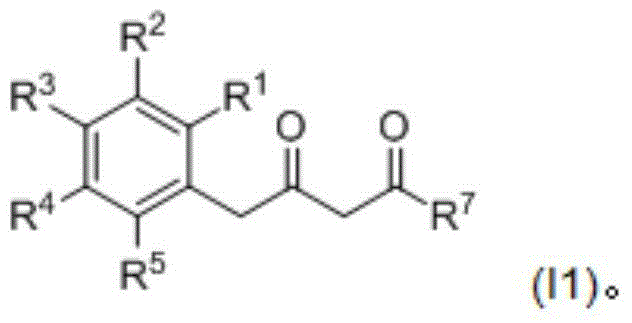

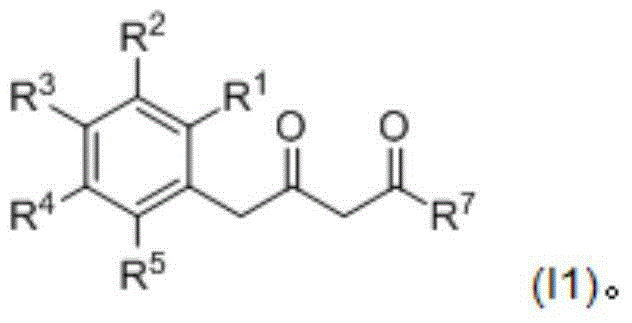

Preparation method of sitagliptin intermediate

A compound, selected technology, applied in the preparation of organic compounds, carboxylic acid ester preparation, chemical instruments and methods, etc., can solve problems such as the environment and adverse effects of operators

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

[0032] In order to enable those skilled in the art to better understand the technical solutions of the present invention, some non-limiting examples are further disclosed below to further describe the present invention in detail.

[0033] The reagents used in the present invention can be purchased from the market or can be prepared by the methods described in the present invention.

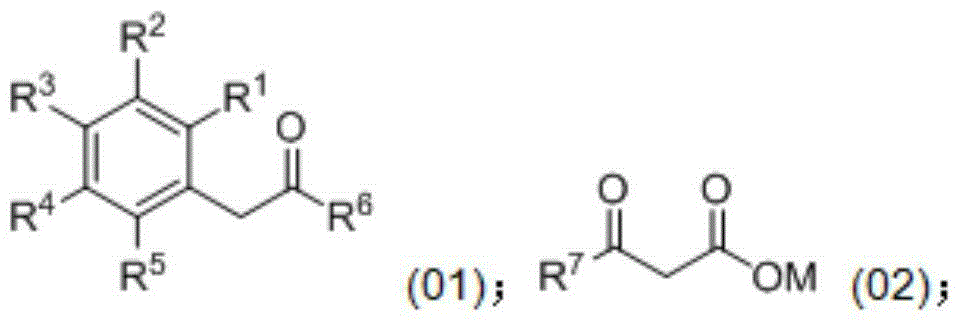

Embodiment 1

[0035] 17.85 grams of monoethyl malonate potassium salt, 22 milliliters of triethylamine and 11.97 grams of anhydrous magnesium chloride were added to 120 milliliters of stirred anhydrous ethyl acetate, and stirred at room temperature for 2 hours; 2,4,5-trifluoro Stir 9.5 g of phenylacetic acid and 9.73 g of N,N'-carbonyldiimidazole in 50 ml of ethyl acetate for 0.5 hours, then add the mixture to the aforementioned reaction solution; the mixed reaction solution is stirred at 50°C-60°C for reaction After 6 hours to 8 hours, lower the temperature to 15°C-25°C, add 10% hydrochloric acid aqueous solution, adjust the pH to less than 3, separate layers, wash the organic layer with saturated brine three times, dry the organic layer with anhydrous sodium sulfate and concentrate Evaporate to dryness to obtain 13.2 g of oil.

Embodiment 2

[0037] 17.85 grams of monoethyl malonate potassium salt, 22 milliliters of triethylamine and 11.97 grams of anhydrous magnesium chloride were added to 120 milliliters of stirred isopropyl acetate, stirred at room temperature for 2 hours, and 2,4,5-trifluorobenzene Stir 9.5 g of acetic acid and 9.73 g of N,N'-carbonyldiimidazole in 50 ml of isopropyl acetate for 0.5 hour, add this mixture to the aforementioned reaction solution, and stir the mixed reaction solution at 50°C-60°C for reaction After 6 hours to 8 hours, lower the temperature to 15°C-25°C, add 10% hydrochloric acid aqueous solution, adjust the pH to less than 3, separate layers, wash the organic layer with saturated brine three times, dry the organic layer with anhydrous sodium sulfate and concentrate Evaporate to dryness to obtain 13.1 g of oil.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com