Nonlinear polymer having doxorubicin structure, and preparation method and application thereof

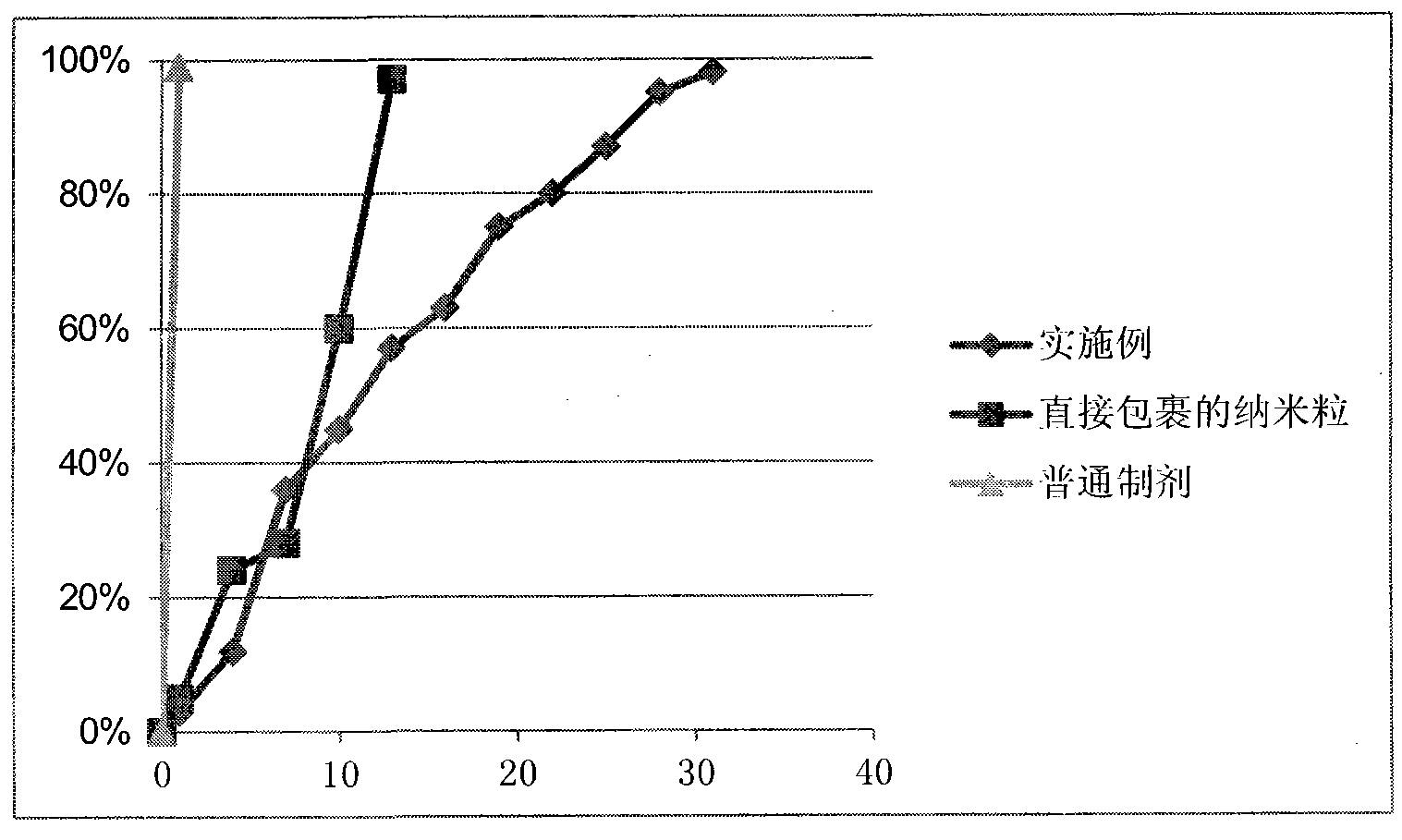

A doxorubicin and polymer technology is applied to medical preparations containing active ingredients, medical preparations with non-active ingredients, organic active ingredients, etc. It can solve problems such as low solubility, short half-life, and high toxicity, and achieve Easy to dissolve, excellent effect, half-life extended effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

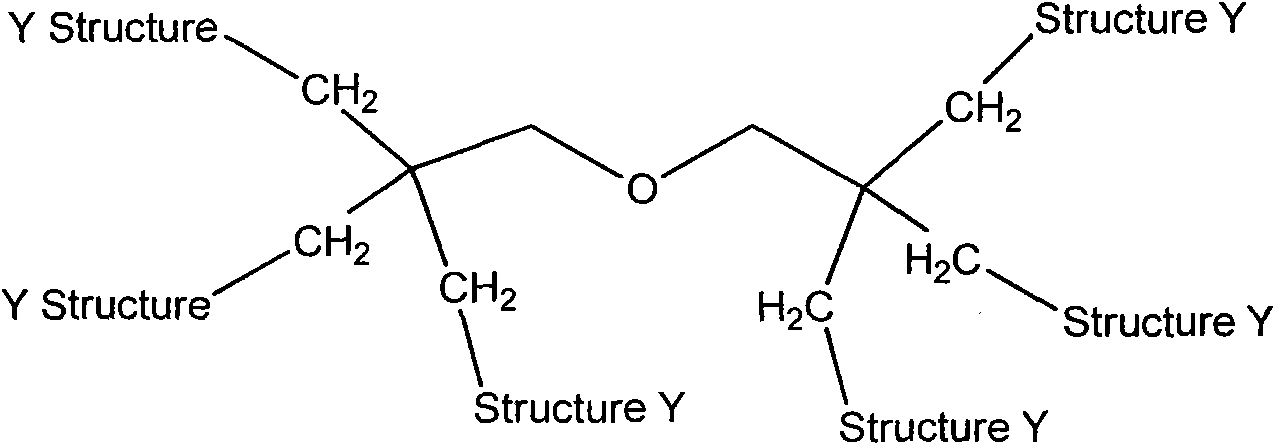

Method used

Image

Examples

Embodiment 1

[0051] 1) A mixture of 80 g of sebacic acid in 800 ml of acetic anhydride was refluxed to form acetyl-sebacic acid;

[0052] 2) Mix the 1st) step with the 6-arm polyethylene glycol 14g product terminated with hydroxyl and put it into a flask, and at 180 ° C under reduced pressure solution polymerization reaction 1 hour; ether washed and dried;

[0053] 3) Put 120 mg of doxorubicin and 800 mg of polymer from step 2 into 8 ml of dimethyl sulfoxide and 12 ml of dichloromethane solution for 48 hours; ultrasonicate for 3 minutes; then place in an oven for 1 hour; The homogenizer was stirred at an ultra-high speed at 20 degrees for 3 minutes, and then put into a 1% polyvinyl alcohol solution and stirred at 600 rpm for 2 hours; centrifuged, collected, and freeze-dried to obtain nanoparticles of the final product.

Embodiment 2

[0055] 1) A mixture of 100 g of sebacic acid in 900 ml of acetic anhydride was refluxed to form acetyl-sebacic acid;

[0056] 2) Mix the 1st) step with the 6-arm polyethylene glycol 19g product terminated with hydroxyl and put it into a flask, and at 180 DEG C. under reduced pressure for 1 hour; ether washed and dried;

[0057] 3) Put 200mg of doxorubicin and 1000mg of polymer from step 2 into 6ml of dimethyl sulfoxide and 14ml of dichloromethane solution for 24 hours; ultrasonicate for 2 minutes; then put in an oven for 2 hours; at minus 10 degrees The medium homogenizer was stirred at an ultra-high speed for 2 minutes, and then put into a 10% cholic acid solution and stirred at 600 rpm for 3 hours; after centrifugation, collection, and freeze-drying, the nanoparticles of the final product were obtained.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com