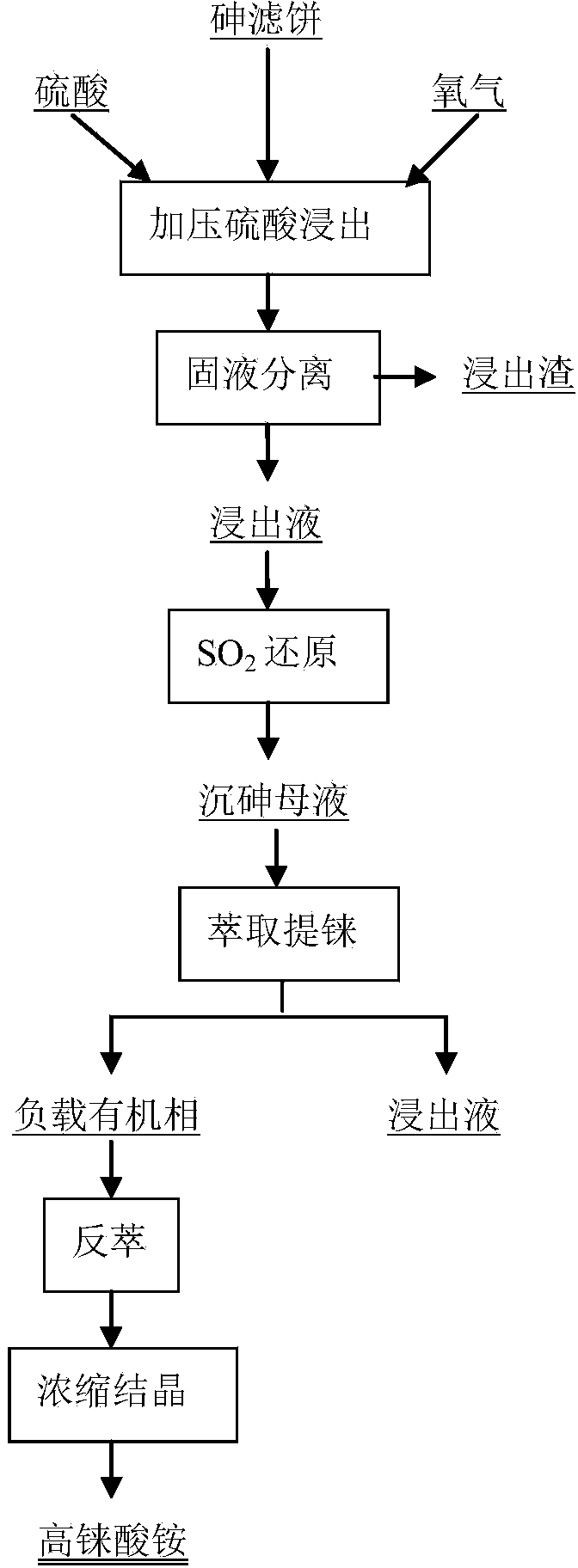

Method for recovering rhenium from arsenic sulfide pressurization leach liquor

A pressure leaching and arsenic sulfide technology, applied in the field of hydrometallurgy, can solve the problems of low regeneration times, limited resin exchange capacity, and restrictions on large-scale industrial application, and achieve the effect of convenient storage and transportation and high rhenium recovery rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0016] The filter cake containing rhenium and arsenic treated in this example comes from a domestic copper smelting enterprise, and its main chemical composition is (%): As12.14~13.45, Sb 0.065~0.078, Bi 1.23~1.54, Au 2.98~3.21 (g / t), Ag 43.16~45.18(g / t), Cu8.77~9.37, Pb 3.99~4.03, Zn 0.67~0.84, S 5.13~6.43, Re 0.09~0.11, Se 0.34~0.41, Te0.0032~0.0034 , In 0.0078~0.0089, Fe 0.19~0.25, Sn 0.29~0.35, and the rest are impurities.

[0017] Put 200g of rhenium-containing arsenic filter cake in a GAS type 2L vertical autoclave, add additives, acid, water, etc., mix them in a certain proportion, put them in the axe, seal, stir, and heat up. When the temperature rises to the set value (100°C), adjust the oxygen partial pressure to the set value (0.4Mpa) with oxygen, and start timing. After reacting for 3 hours, pass cooling water to cool down, open the valve to reduce the pressure, after the material is separated from solid and liquid, the leached residue is put into an oven (60°C) ...

Embodiment 2

[0020] The filter cake containing rhenium and arsenic treated in this example comes from a domestic copper smelting enterprise, and its main chemical composition is (%): As12.14~13.45, Sb 0.065~0.078, Bi 1.23~1.54, Au 2.98~3.21 (g / t), Ag 43.16~45.18(g / t), Cu8.77~9.37, Pb 3.99~4.03, Zn 0.67~0.84, S 5.13~6.43, Re 0.09~0.11, Se 0.34~0.41, Te0.0032~0.0034 , In 0.0078~0.0089, Fe 0.19~0.25, Sn 0.29~0.35, and the rest are impurities.

[0021] Put 100g of rhenium-containing arsenic filter cake in a GAS type 2L vertical autoclave, add additives, acid, water, etc., mix them in a certain proportion, put them into the axe, seal, stir, and heat up. When the temperature rises to the set value (60°C), adjust the oxygen partial pressure to the set value (0.8Mpa) with oxygen, and start timing. After reacting for 2 hours, pass cooling water to cool down, open the valve to reduce the pressure, after the material is separated from solid and liquid, the leaching residue is put into an oven (50°C...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com