Method for manufacturing diamond device

A diamond and device technology, applied in the field of semiconductor devices, can solve the problems of increased gate-source and gate-drain resistance, decreased transistor frequency performance, etc., and achieve the effects of reducing ohmic contact resistance, improving performance and simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

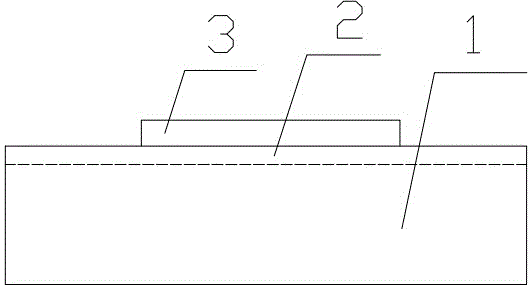

[0029] In the first step, the active area on the surface of the diamond semiconductor material with a p-type conductive channel is covered with photoresist;

[0030] The second step is to use the photoresist as a mask to etch the diamond conductive channel outside the active area with oxygen plasma for 10 minutes to remove the conductive channel;

[0031] The third step is to cover the photoresist outside the source and drain positions;

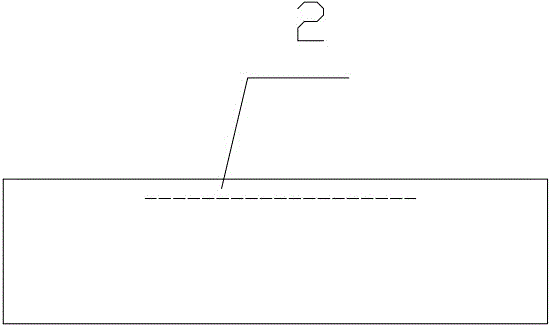

[0032] The fourth step is to transfer and cover the double-layer graphene grown on the Ni substrate by CVD method on the diamond surface;

[0033] The fifth step is to deposit ohmic contact metal Ti / Au 10 nm / 200nm on the graphene;

[0034] The sixth step is peeling off to form source and drain;

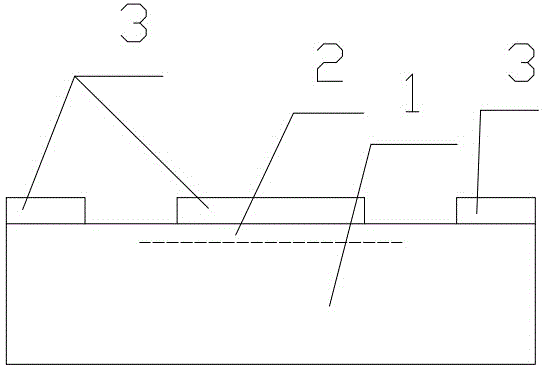

[0035] In the seventh step, electron beam lithography prepares a T-shaped grid with a grid length of 100 nm, evaporates 200 nm of Al grid metal, and peels off to form a diamond device.

Embodiment 2

[0037] In the first step, the active area on the surface of the diamond semiconductor material with an n-type conductive channel is covered with photoresist;

[0038] The second step is to use the photoresist as a mask to etch the diamond conductive channel outside the active area with oxygen plasma for 10 minutes to remove the conductive channel;

[0039] The third step is to cover the photoresist outside the source and drain positions;

[0040] The fourth step is to transfer and cover the double-layer graphene grown on the Ni substrate by CVD method on the diamond surface;

[0041] The fifth step is to deposit ohmic contact metal Ti / Au 10 nm / 200nm on the graphene;

[0042] The sixth step is peeling off to form source and drain;

[0043] In the seventh step, electron beam lithography prepares a T-shaped grid with a grid length of 100 nm, evaporates 200 nm of Al grid metal, and peels off to form a diamond device.

Embodiment 3

[0045] In the first step, the active area on the surface of the diamond semiconductor material with a p-type conductive channel is covered with photoresist;

[0046] The second step is to use the photoresist as a mask to etch the diamond conductive channel outside the active area with oxygen plasma for 10 minutes to remove the conductive channel;

[0047] The third step is to cover the photoresist outside the source and drain positions;

[0048] The fourth step is to transfer and cover the graphene grown on the Cu substrate by CVD method on the diamond surface;

[0049] The fifth step is to deposit ohmic contact metal Au 200nm on the graphene;

[0050] The sixth step is peeling off to form source and drain;

[0051] In the seventh step, electron beam lithography prepares a T-shaped grid with a grid length of 100 nm, evaporates 200 nm of Al grid metal, and peels off to form a diamond device.

[0052] In the present invention, a graphene layer is inserted between the diamond ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com