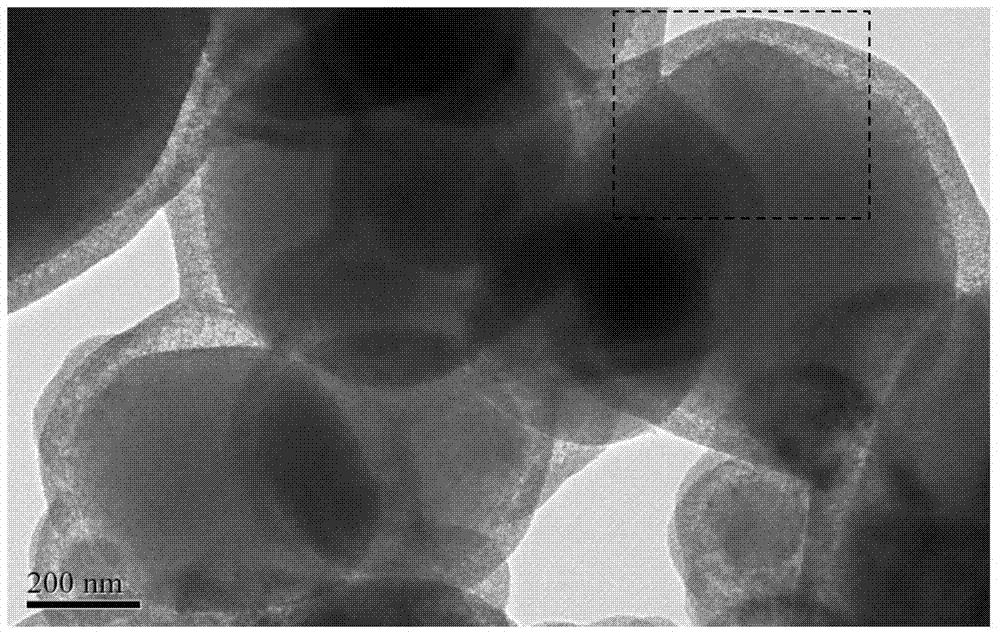

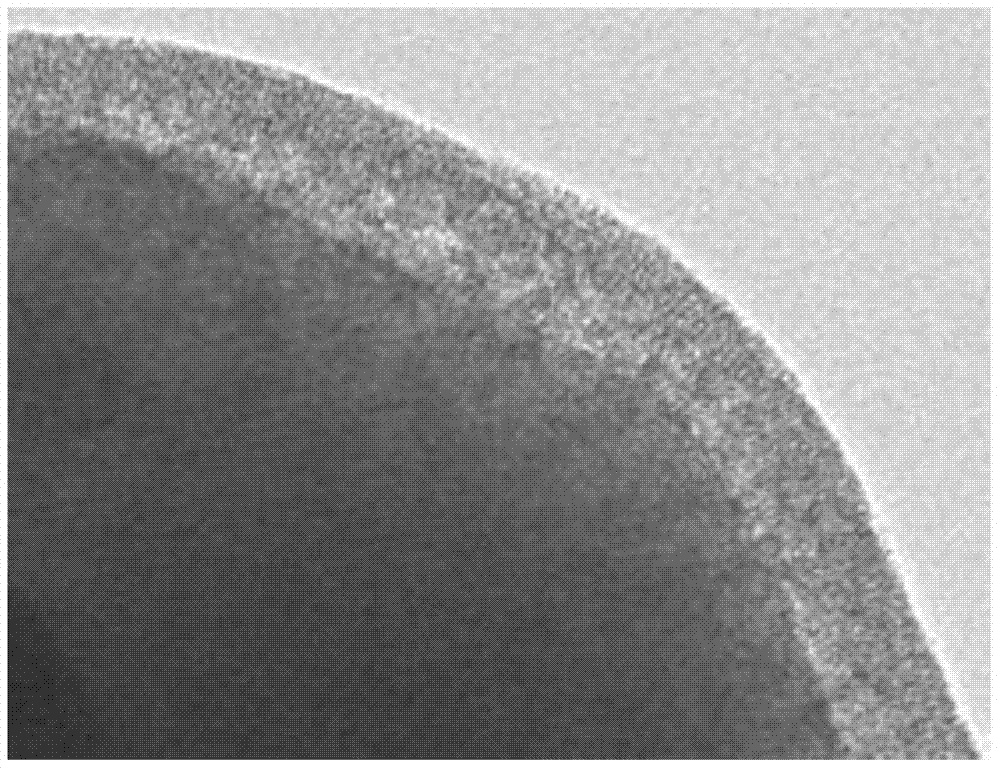

Yolk-eggshell structured catalyst and preparation method and application thereof

A catalyst and eggshell technology, which is applied in the field of catalyst preparation, can solve the problems of complex preparation process, long synthesis cycle, and environmental pollution of strong acid etchant, and achieve the effects of low reaction temperature, reduced production cost, and high stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

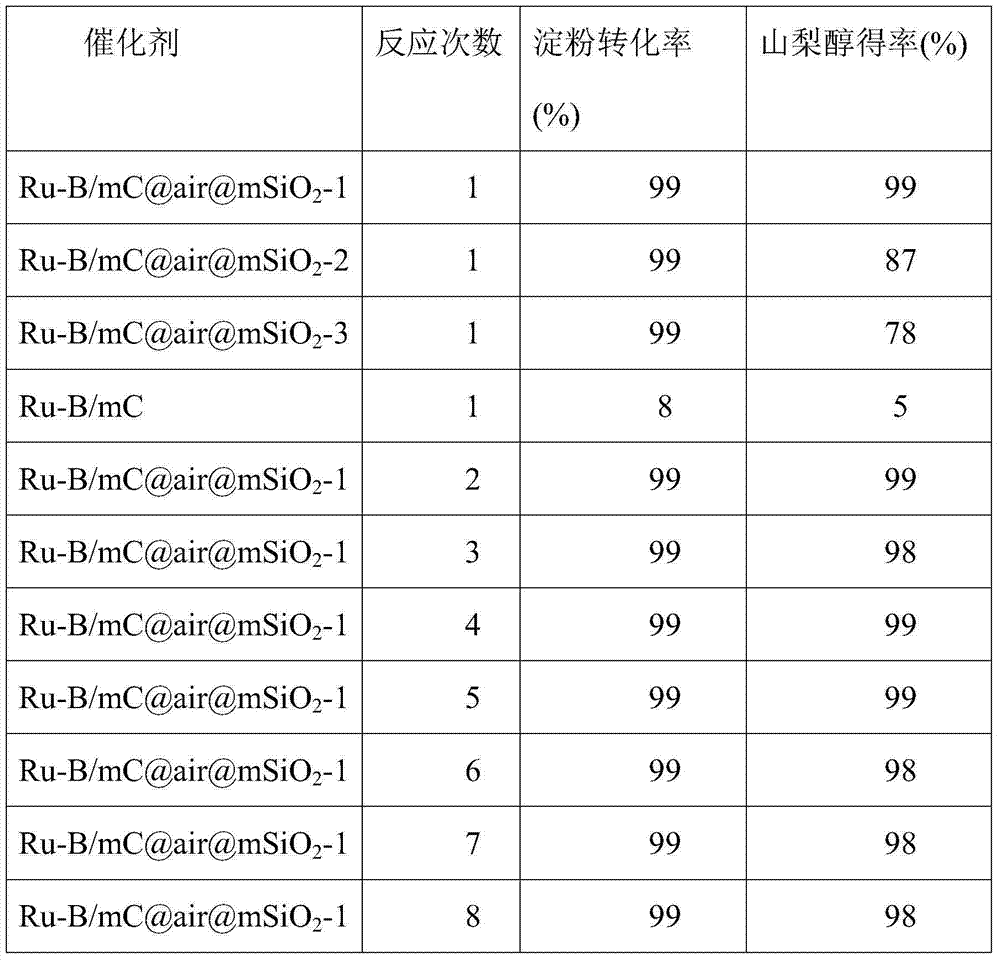

Examples

Embodiment 1

[0021] (1) Add 0.15 g of mesoporous carbon spheres to 0.66 mL of 0.06 mol / L NH4RuCl6 aqueous solution, ultrasonicate for 15 minutes, let stand for 12 hours, and dry at 100°C for 30 minutes. Under vigorous stirring at 0°C, 1.5 mL of 0.5 mol / L KBH4 aqueous solution was added dropwise to the above solution, and stirring was continued for 30 minutes after the dropwise addition. Centrifugation yielded a black solid, which was washed repeatedly with deionized water until neutral.

[0022] (2) The product obtained in step (1) was added to a mixed solution of 27 mL of ethanol, 50 mL of water, 0.1 g of cetyltrimethylammonium bromide, 37 μL of dodecanol and 1 mL of 30 mg / mL sodium hydroxide, and sonicated for 15 minutes. After stirring for 60 minutes, 1.6 mL of tetraethyl orthosilicate was slowly added dropwise. After stirring at 60°C for 3 hours, the product was washed by centrifugation, added to 100 mL of acetone, and stirred and refluxed at 55°C for 48 hours.

[0023] (3) adding th...

Embodiment 2

[0026] (1) Add 0.15g of mesoporous carbon spheres to 0.66mL of 0.06mol / L NH 4 RuCl 6 In aqueous solution, sonicated for 15 minutes, allowed to stand for 12 hours, and dried at 100°C for 30 minutes. Add 10 mL of 2 mol / L KBH dropwise to the above solution at 0 °C with vigorous stirring. 4 The aqueous solution was added dropwise and continued to stir for 30 minutes. Centrifugation yielded a black solid, which was washed repeatedly with deionized water until neutral.

[0027] (2) The product obtained in step (1) was added to a mixed solution of 27 mL of ethanol, 50 mL of water, 0.1 g of cetyltrimethylammonium bromide, 37 μL of dodecanol and 1 mL of 30 mg / mL sodium hydroxide, and sonicated for 15 minutes. After stirring for 60 minutes, 1.6 mL of tetraethyl orthosilicate was slowly added dropwise. After stirring at 60°C for 3 hours, the product was washed by centrifugation, added to 100 mL of acetone, and stirred and refluxed at 55°C for 48 hours.

[0028] (3) adding the produc...

Embodiment 3

[0030] (1) Add 0.15g of mesoporous carbon spheres to 0.66mL of 0.06mol / L NH 4 RuCl 6 In aqueous solution, sonicated for 15 minutes, allowed to stand for 12 hours, and dried at 100°C for 30 minutes. Add 10 mL of 2 mol / L KBH dropwise to the above solution at 0 °C with vigorous stirring. 4 The aqueous solution was added dropwise and continued to stir for 30 minutes. Centrifugation yielded a black solid, which was washed repeatedly with deionized water until neutral.

[0031] (2) The product obtained in step (1) was added to a mixed solution of 27 mL of ethanol, 50 mL of water, 0.1 g of cetyltrimethylammonium bromide, 37 μL of dodecanol and 1 mL of 30 mg / mL sodium hydroxide, and sonicated for 15 minutes. After stirring for 60 minutes, 1.6 mL of tetraethyl orthosilicate was slowly added dropwise. After stirring at 60°C for 3 hours, the product was washed by centrifugation, added to 100 mL of acetone, and stirred and refluxed at 55°C for 48 hours.

[0032] (3) adding the produc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com