Preparation and application of bifluorescent carbon nanodots

A technology of carbon nano-dots and dual fluorescence, applied in nano-carbon, nanotechnology, nano-optics, etc., can solve the problems of complex preparation of ratiometric fluorescent probes, poor water solubility, etc., and achieve non-toxic side effects, improved sensitivity, and good reproducibility Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

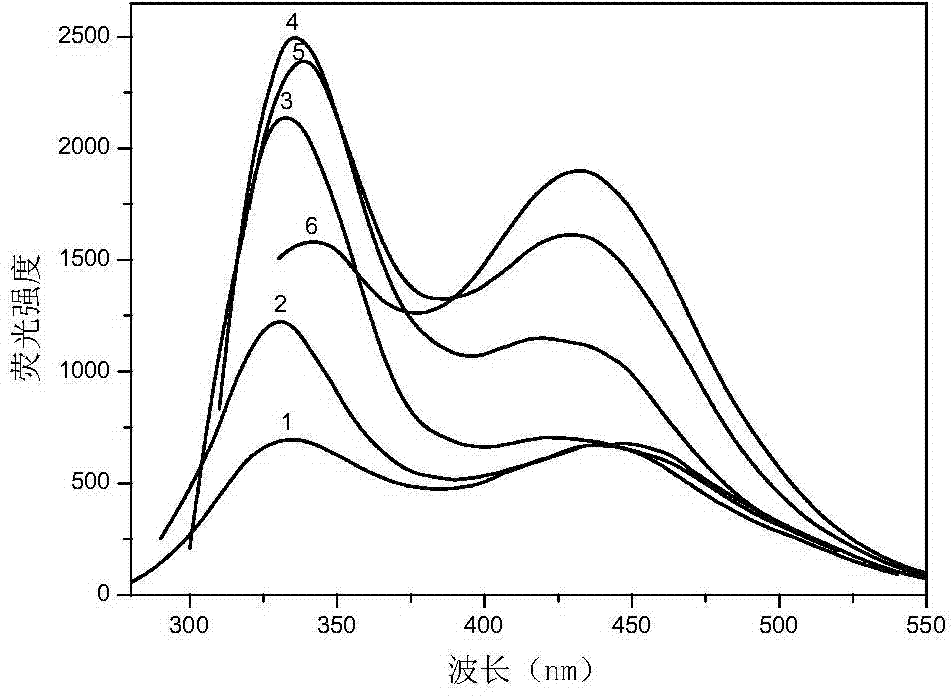

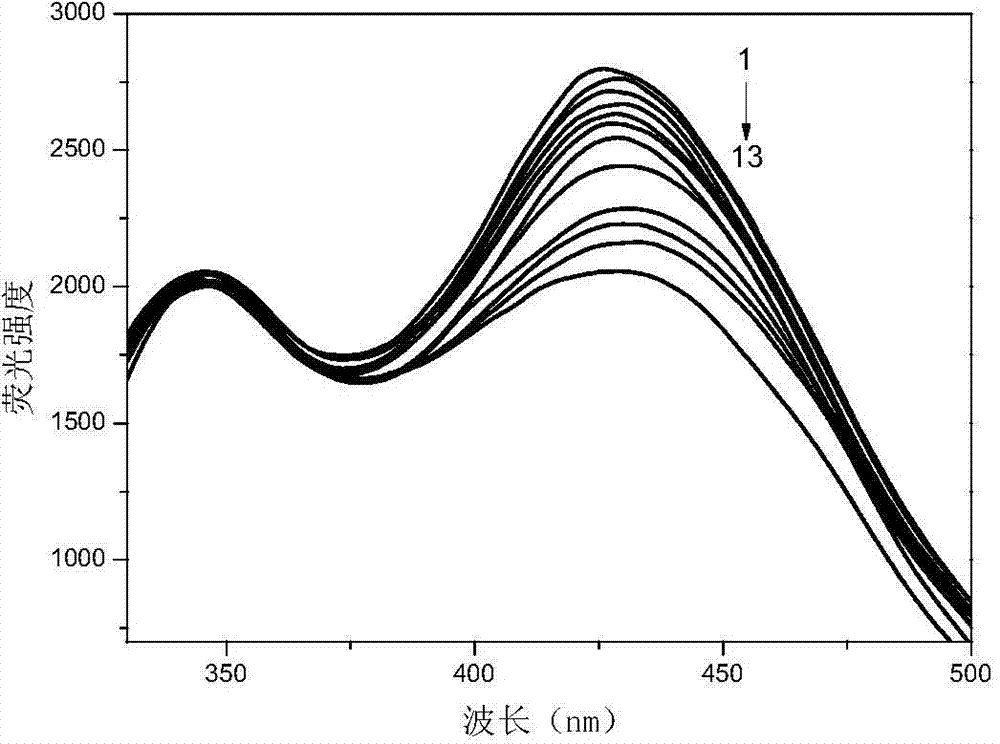

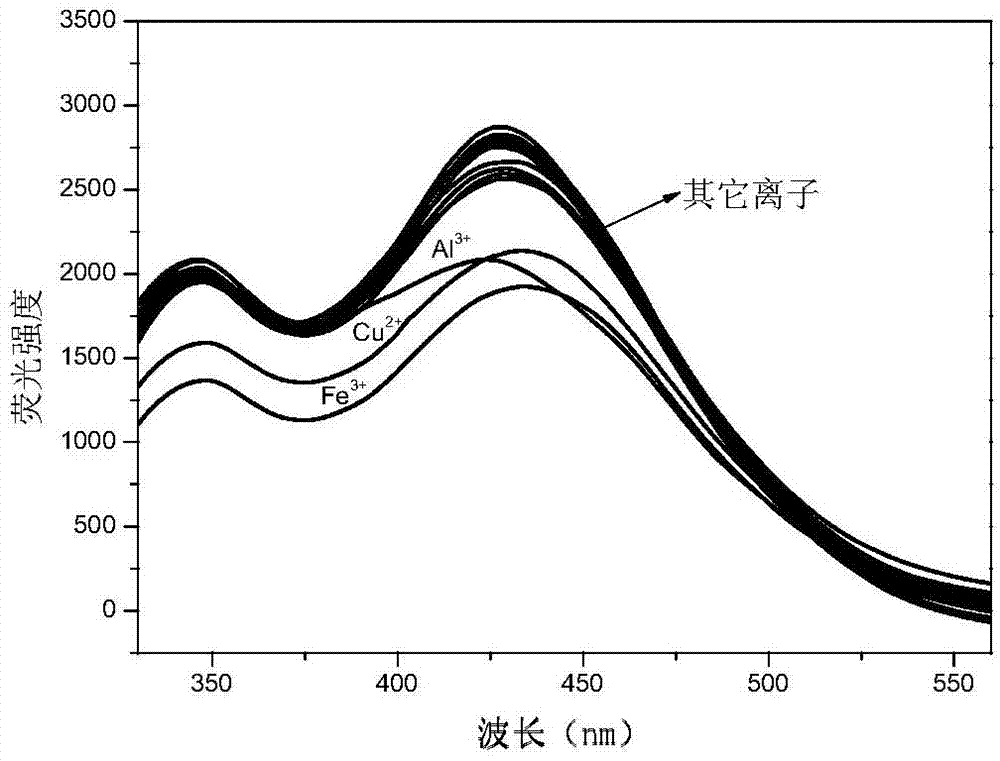

[0030] Preparation of dual fluorescent carbon nanodots:

[0031] (1) Carbonize naked oats at 400°C for 2 hours;

[0032] (2) Grinding the carbonized product into powder;

[0033] (3) Mix 1 g of naked oat carbonized powder prepared in step (2) with 80 mL of water, and heat in microwave for 12 minutes to obtain a black turbid liquid;

[0034] (4) Centrifuge the black turbid liquid with a centrifuge at 3500r / min for 15-20min to remove the black precipitate and obtain a transparent supernatant;

[0035] (5) Freeze-dry the transparent supernatant at -50°C until it becomes powdery to obtain carbon nanodots.

[0036] The transmission electron microscope image of the prepared dual fluorescent carbon nanodots is shown in figure 1 .

[0037] The pictures of the prepared double fluorescent carbon nanodot aqueous solution under the irradiation of fluorescent lamp and ultraviolet lamp (wavelength of 254nm and 365nm) are shown in figure 2, wherein 1 is the picture of the aqueous solut...

Embodiment 2

[0040] Preparation of dual fluorescent carbon nanodots:

[0041] (1) Carbonize naked oats at 300°C for 3 hours;

[0042] (2) Grinding the carbonized product into powder;

[0043] (3) Mix 1 g of naked oat carbonized powder prepared in step (2) with 90 mL of water, and heat in microwave for 8 minutes to obtain a black turbid liquid;

[0044] (4) Centrifuge the black turbid liquid with a centrifuge at 3500r / min for 15-20min to remove the black precipitate and obtain a transparent supernatant;

[0045] (5) Freeze-dry the transparent supernatant at -50°C until it becomes powdery to obtain carbon nanodots.

Embodiment 3

[0047] Preparation of dual fluorescent carbon nanodots:

[0048] (1) Carbonize naked oats at 200°C for 4 hours;

[0049] (2) Grinding the carbonized product into powder;

[0050] (3) Mix 1 g of naked oat carbonized powder prepared in step (2) with 100 mL of water, and heat in microwave for 16 minutes to obtain a black turbid liquid;

[0051] (4) Centrifuge the black turbid liquid with a centrifuge at 3500r / min for 15-20min to remove the black precipitate and obtain a transparent supernatant;

[0052] (5) Freeze-dry the transparent supernatant at -50°C until it becomes powdery to obtain carbon nanodots.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com