Coking wastewater compound chemical and preparation method thereof and application thereof

A coking wastewater and medicament technology, which is applied in chemical instruments and methods, water/sewage treatment, neutralized water/sewage treatment, etc., can solve problems such as high chroma and toxic substance content, and cannot meet the requirements of biological treatment, and achieve pore The effect of high density, fast sedimentation speed and large specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

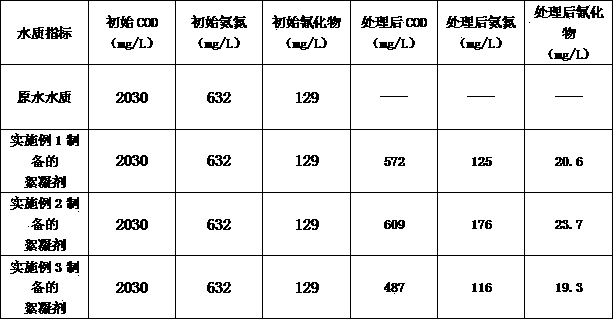

Embodiment 1

[0039] Take 30% magnesium sulfate, 20% potassium dihydrogen phosphate, 20% sodium dihydrogen phosphate, 10% sodium hydroxide, and 20% powdered activated carbon. After the above raw materials are fully mixed, dry at 100°C for 60 minutes to make a denitrification agent; take 20% ferric chloride, 20% ferric sulfate, 30% aluminum sulfate, 5% cationic polyacrylamide, calcium hydroxide 20%, diatomaceous earth 5%, the above raw materials are fully mixed, and dried at 60°C for 90 minutes to make a coagulant.

Embodiment 2

[0041] Get 20% of magnesium carbonate, 30% of magnesium chloride, 30% of disodium hydrogen phosphate, 15% of sodium hydroxide, and 5% of powdered activated carbon. After the above raw materials are fully mixed, dry at 90°C for 90 minutes to make a denitrification agent; take 30% ferric chloride, 20% ferric sulfate, 25% aluminum chloride, 5% anionic polyacrylamide, sodium hydroxide 10%, diatomaceous earth 10%, after mixing the above raw materials thoroughly, dry at 90°C for 30 minutes to make coagulant.

Embodiment 3

[0043] Take 36% of magnesium chloride, 32% of dipotassium hydrogen phosphate, 25% of calcium hydroxide, and 7% of powdered activated carbon. After fully mixing the above raw materials, dry at 100°C for 60 minutes to make a denitrification agent; take ferric sulfate 42%, Aluminum Chloride 36%, Cationic Polyacrylamide 5%, Calcium Hydroxide 12%, Powdered Diatomaceous Earth 5%, after mixing the above raw materials thoroughly, dry at 60°C for 45 minutes to make coagulation agent.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com