Method for treatment and cyclic utilization of sulfuric acid waste water containing heavy metal

A technology for wastewater treatment and heavy metals, applied in water/sewage multi-stage treatment, water/sludge/sewage treatment, chemical instruments and methods, etc., can solve the problems that wastewater cannot be recycled, sulfuric acid wastewater treatment is achieved, and the operation is not stable enough , to achieve stable operation, avoid fouling, and high treatment efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

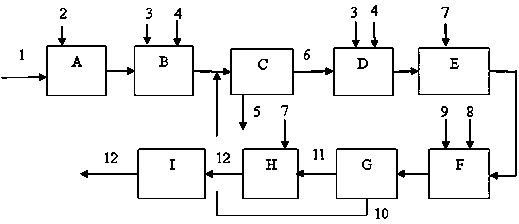

[0027] The technological process of the inventive method sees figure 1 . Heavy metal-containing sulfuric acid wastewater 1 (containing H 2 SO 4 4.37%, As 39.1mg / L, Pb 5.4mg / L, F 102.6mg / L) into the machine mixing reaction tank A, add lime 2 under mechanical mixing for treatment, the treatment time is 15 (or 10, 20) minutes, The pH value is 11.4 (or 11.0, 12.0), so that the fluorine in the wastewater produces calcium fluoride precipitation; the effluent from the machine-mixed reaction tank A enters the aeration reaction tank B, and the Fe / As molar ratio is 4 (or 6, 8 ) by adding ferrous sulfate 3 and compressed air 4 for treatment, the treatment time is 30 (or 20, 40) minutes, the pH value is 11.1 (or 10.5, 11.5), so that the ferrous iron in the wastewater is oxidized to ferric iron , arsenic produces ferric arsenate and ferric arsenite precipitation, and lead produces flocculation precipitation; the effluent from the aeration reaction tank B enters the filter press C to fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com