System for recycling wastewater from circulating cooling water by adopting membrane process

A sewage and circulating water technology, applied in water/sewage multi-stage treatment, water/sludge/sewage treatment, chemical instruments and methods, etc., can solve problems such as no disposal plan proposed, effective removal of scale-causing organic matter, etc. Achieve the effect of reducing scale-causing components and refractory organic matter, good stability and high water recovery rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

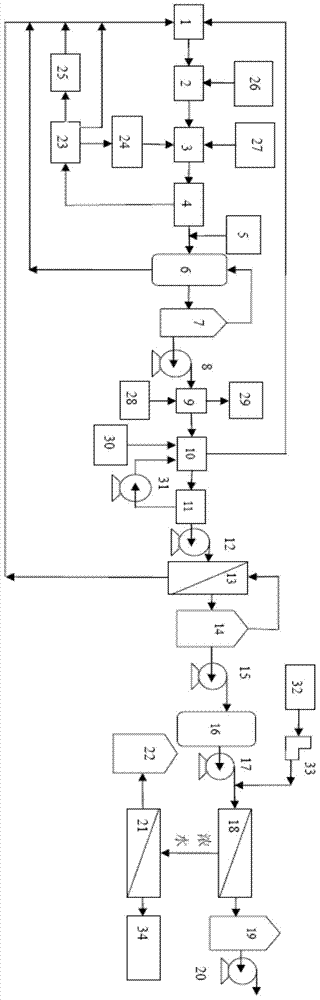

[0024] The present invention is described in further detail below in conjunction with accompanying drawing:

[0025] refer to figure 1 , the recycling system of circulating water sewage membrane method according to the present invention comprises a pipeline mixer 2, a reaction tank 3, a sedimentation tank 4, a pH adjustment device 5, a filter 6, an ozone contact reaction tank 9, a biological activated carbon filter tank 10, Ultrafiltration device 13, scale inhibitor tank 32, reverse osmosis device 18, fresh water tank 19, electrodialysis device 21, electrodialysis water production tank 22, coagulant dosing system 26, softener dosing system 27, ozone generator 28 , and the raw water pool 1 for placing sewage; the coagulant outlet of the coagulant dosing system 26 and the water outlet of the raw water pool 1 pass through the pipeline mixer 2 manifolds, and the inlet of the reaction tank 3 is connected with the pipeline mixer respectively 2 is connected with the softener outlet ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com