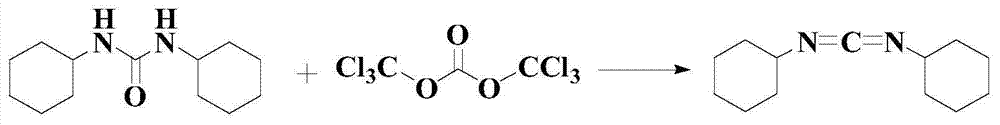

Synthesis method of dicyclohexyl carbodiimide

The technology of a dicyclohexylcarbodiimide and a synthesis method is applied in the synthesis of dicyclohexylcarbodiimide and the synthesis field of imine compounds, and can solve the problems of complicated steps, unstable reaction, insufficient product yield and the like, Achieve the effect of improving reaction yield, reducing production cost and avoiding production difficulties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

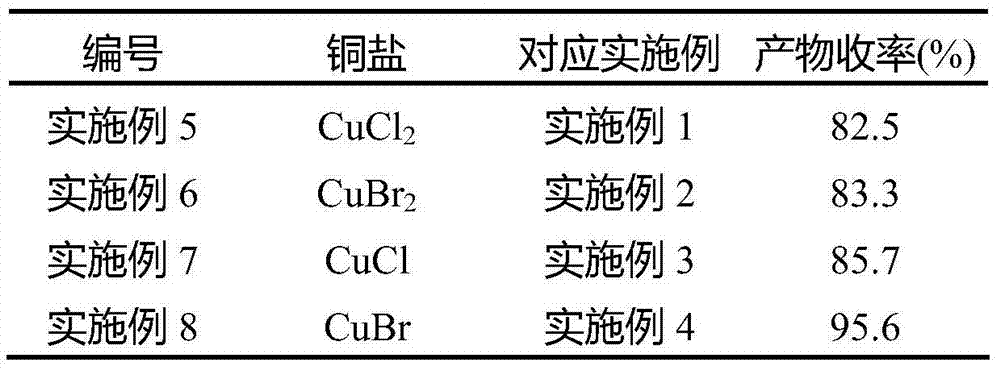

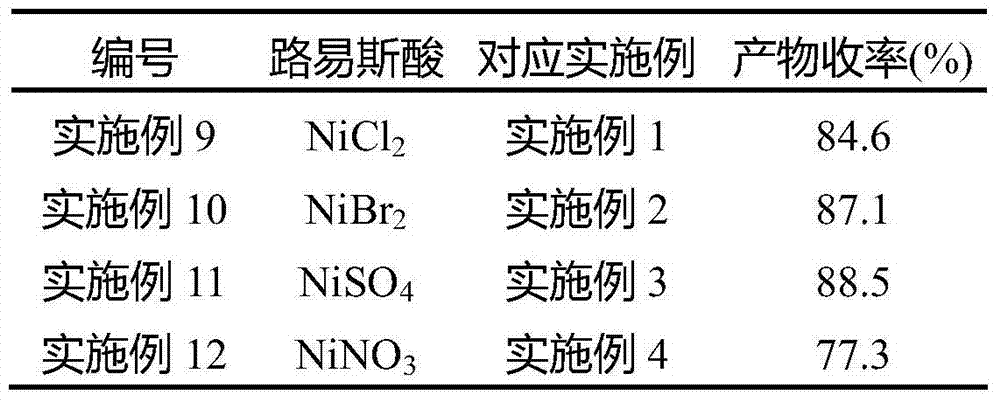

Examples

preparation example 1

[0033] Weigh Cu(acac) according to the mass ratio of 1:0.4:0.6 2 , nickel p-toluenesulfonate and ammonium cerium nitrate, and grind and mix uniformly to obtain the composite catalyst of the present invention, which is specifically applied in the following examples.

Embodiment 1

[0035] Add 800ml of acetonitrile and 100g of dicyclohexyl urea successively to the reactor at room temperature, then stir evenly, add 220g of solid phosgene, then add 0.4g of catalyst and 12g of reaction auxiliary sodium lauryl sulfate, raise the temperature to 35 ℃, heat-retaining and stirring for 2.5 hours; after the reaction, pass ammonia gas to adjust the pH to 7.5, and then suction filter while it is hot. The obtained filtrate is first evaporated to remove the solvent under normal pressure, and then distilled under reduced pressure under a pressure of 1.35-1.54kPa. Fractions at 153-156°C were collected and dried in an oven under vacuum to give dicyclohexylcarbodiimide as a white crystalline solid in 99.5% yield and 99.1% purity (HPLC).

Embodiment 2

[0037]Add 900ml of acetonitrile and 100g of dicyclohexyl urea successively to the reactor at room temperature, then stir evenly, add 250g of solid phosgene, then add 0.5g of catalyst and 12g of reaction aid sodium lauryl sulfate, raise the temperature to 40 ℃, heat-retaining and stirring for 3 hours; after the reaction, pass ammonia gas to adjust the pH to 8, and then suction filter while it is hot. The obtained filtrate is first evaporated to remove the solvent at normal pressure, and then distilled under reduced pressure under a pressure of 1.35-1.54kPa to collect Fraction at 153-156°C and vacuum-dried in an oven gave dicyclohexylcarbodiimide as a white crystalline solid in 99.2% yield and 98.9% purity (HPLC).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com