Production and processing technology of light phase substance pentosan of wheatmeal and wheat flour

A technology of wheat flour and processing technology, which is applied in the field of polysaccharide processing, can solve the problems of poor utilization of light phase liquid, insufficient utilization of raw materials, and increased processing costs, so as to achieve environmental protection, high added value of products, and automation high degree of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

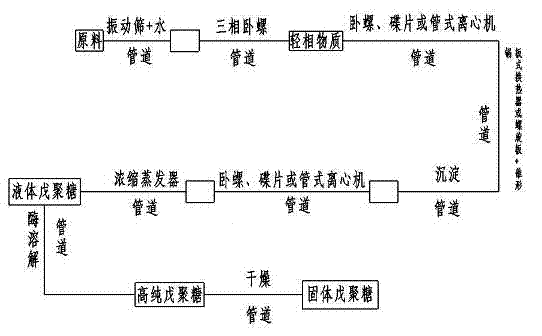

Embodiment 1

[0013] A production and processing technology of wheat flour and the light phase substance of wheat flour - pentosan. The production and processing steps are as follows: ① take wheat flour or wheat flour as raw material, add water and make dough slurry; Carry out centrifugation to obtain light phase substances, wheat starch, gluten; ③Use a decanter, disc or tubular centrifuge to separate the light phase substances through membrane filtration with a separation factor of 5000-20000, and then use a vibrating screen for further separation. Filter to separate large particles and impurities; ④ Preheat the light phase material with a plate heat exchanger or spiral plate, then enter the conical pot, steam cook at a temperature of 50°C-200°C, and then use vibration Sieve for re-filtering; ⑤ Precipitate the filtered liquid to remove protein, starch, crude fiber and bran in the upper and lower layers to obtain a solution; Separation of the solution under certain conditions; ⑦The separate...

Embodiment 2

[0015] A production and processing technology of wheat flour and the light phase substance of wheat flour - pentosan. The production and processing steps are as follows: ① take wheat flour or wheat flour as raw material, add water and make dough slurry; Carry out centrifugation to obtain light phase substances, wheat starch, gluten; ③Use a decanter, disc or tubular centrifuge to separate the light phase substances through membrane filtration with a separation factor of 5000-20000, and then use a vibrating screen for further separation. Filter to separate large particles and impurities; ④ Preheat the light phase material with a plate heat exchanger or spiral plate, then enter the conical pot, steam cook at a temperature of 50°C-200°C, and then use vibration Sieve for re-filtering; ⑤ Precipitate the filtered liquid to remove protein, starch, crude fiber and bran in the upper and lower layers to obtain a solution; Separation of the solution under certain conditions; ⑦The separate...

Embodiment 3

[0017] A production and processing technology of wheat flour and the light phase substance of wheat flour - pentosan. The production and processing steps are as follows: ① take wheat flour or wheat flour as raw material, add water and make dough slurry; Carry out centrifugation to obtain light phase substances, wheat starch, gluten; ③Use a decanter, disc or tubular centrifuge to separate the light phase substances through membrane filtration with a separation factor of 5000-20000. Filtration to separate large particles and impurities; ④ Preheat the light phase material with a plate heat exchanger or spiral plate, then enter the conical pot, steam cook at a temperature of 50°C-200°C, and then use vibration Sieve for re-filtering; ⑤ Precipitate the filtered liquid to remove protein, starch, crude fiber and bran in the upper and lower layers to obtain a solution; Separation of the solution under certain conditions; ⑦The separated liquid is concentrated with a concentrated evapora...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com