EVA (Ethylene Vinyl Acetate) glue film capable of reducing PID (Potential-Induced Degradation) phenomena of photovoltaic module, as well as preparation technology thereof

A technology of photovoltaic modules and phenomena, applied in the direction of photovoltaic power generation, adhesives, electrical components, etc., can solve problems such as damage, and achieve the effects of resisting PID phenomena and good water vapor barrier properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

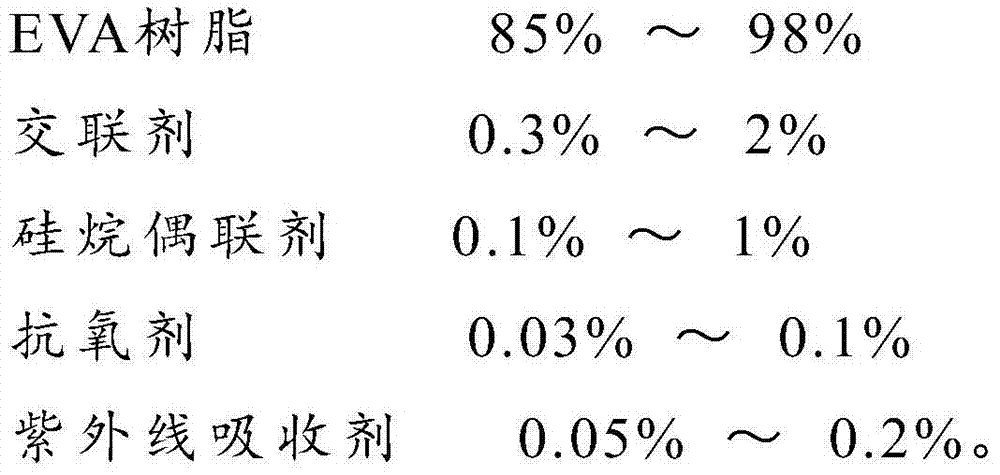

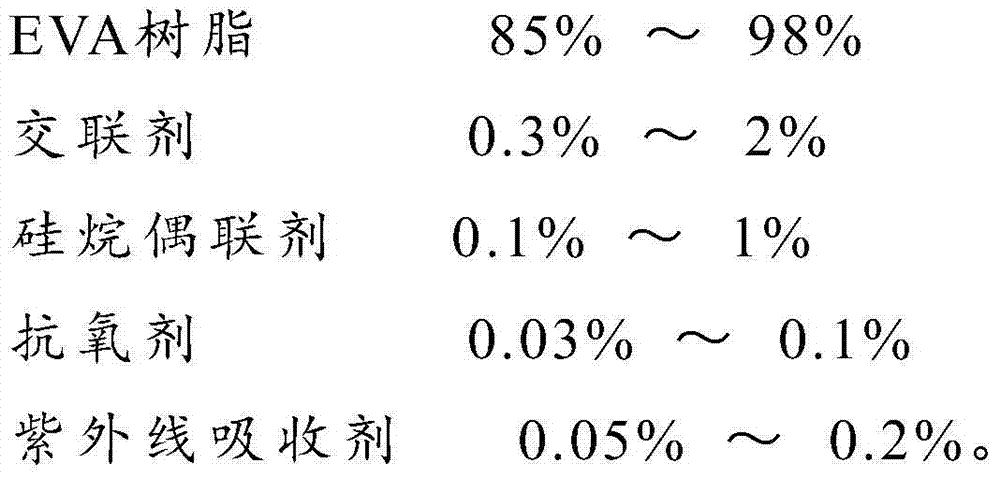

Method used

Image

Examples

Embodiment 1

[0025] Adding 1.5 parts by mass of initiator 2,5-dimethyl-2,5 di-tert-butylperoxyhexane, 0.8 parts by mass of triallyl cyanurate in 100 parts by mass of EVA resin with a vinyl acetate content of 33% Esters, 0.3 parts by mass of β-(3,5-di-tert-butyl-4-hydroxyphenyl) n-octadecyl propionate, 0.3 parts by mass of 2-hydroxy-4-n-octyloxybenzophenone, 0.2 parts by mass of bis(2,2,6,6-tetramethyl-4-piperidinyl) sebacate, 0.5 parts by mass of vinyl tris(β-methoxyethoxy)silane, 0.5 parts by mass of N , N-bis(2,6-diisopropylphenyl)carbodiimide is mixed evenly through a mixer, put into a single-screw extruder, and plasticized at 90°C for extrusion, stretching, traction, and collection The roll is made into an EVA film with a thickness of about 0.5mm. EVA film volume resistivity: 2×10 15 Ω·cm, water vapor transmission rate (38℃ / 90%RH): 15g / (m 2 ·d), damp heat aging resistance (RH85%, 85℃, 1000h): yellowing index (ΔYI): 1.4.

Embodiment 2

[0027] Adding 1.5 parts by mass of initiator 2,5-dimethyl-2,5 di-tert-butylperoxyhexane, 0.8 parts by mass of triallyl cyanurate in 100 parts by mass of EVA resin with a vinyl acetate content of 33% Esters, 0.3 parts by mass of β-(3,5-di-tert-butyl-4-hydroxyphenyl) n-octadecyl propionate, 0.3 parts by mass of 2-hydroxy-4-n-octyloxybenzophenone, 0.2 parts by mass of bis(2,2,6,6-tetramethyl-4-piperidinyl) sebacate, 0.5 parts by mass of vinyl tris(β-methoxyethoxy)silane, 0.75 parts by mass of N , N-bis(2,6-diisopropylphenyl)carbodiimide is mixed evenly through a mixer, put into a single-screw extruder, and plasticized at 90°C for extrusion, stretching, traction, and collection The roll is made into an EVA film with a thickness of about 0.5mm. EVA film volume resistivity: 2.5×10 15 Ω·cm, water vapor transmission rate (38℃ / 90%RH): 14.5g / (m 2 ·d), damp heat aging resistance (RH85%, 85℃, 1000h): yellowing index (ΔYI): 1.4.

Embodiment 3

[0029] Adding 1.5 parts by mass of initiator 2,5-dimethyl-2,5 di-tert-butylperoxyhexane, 0.8 parts by mass of triallyl cyanurate in 100 parts by mass of EVA resin with a vinyl acetate content of 33% Esters, 0.3 parts by mass of β-(3,5-di-tert-butyl-4-hydroxyphenyl) n-octadecyl propionate, 0.3 parts by mass of 2-hydroxy-4-n-octyloxybenzophenone, 0.2 parts by mass of bis(2,2,6,6-tetramethyl-4-piperidinyl) sebacate, 0.5 parts by mass of vinyl tris(β-methoxyethoxy)silane, 1 part by mass of N , N-bis(2,6-diisopropylphenyl)carbodiimide is mixed evenly through a mixer, put into a single-screw extruder, and plasticized at 90°C for extrusion, stretching, traction, and collection The roll is made into an EVA film with a thickness of about 0.5mm. EVA film volume resistivity: 3.0×10 15 Ω·cm, water vapor transmission rate (38℃ / 90%RH): 14.6g / (m 2 ·d), damp heat aging resistance (RH85%, 85℃, 1000h): yellowing index (ΔYI): 1.4.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Volume resistivity | aaaaa | aaaaa |

| Volume resistivity | aaaaa | aaaaa |

| Volume resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com