A kind of surface protective coating for thermal processing of titanium alloy and its application

A technology for protective coatings and titanium alloys, applied in alkali metal silicate coatings, coatings and other directions, can solve the problems of unsatisfactory development of protective coatings for thermal processing of titanium alloys, achieve good anti-oxidation protection and alleviate environmental pollution problems , The effect of coating protection effect is good

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

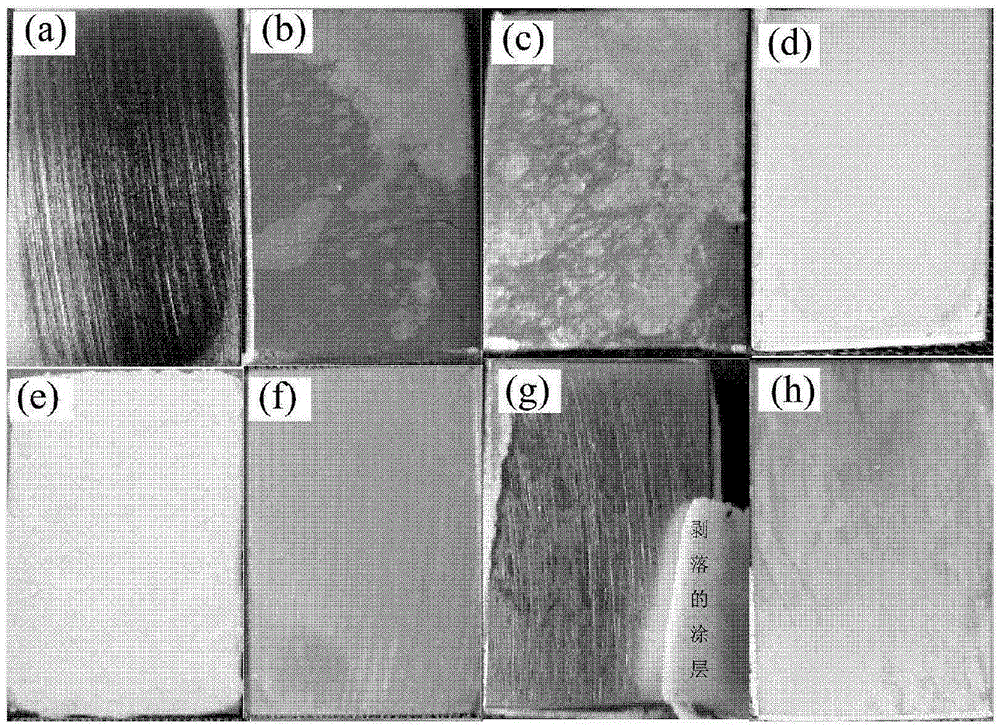

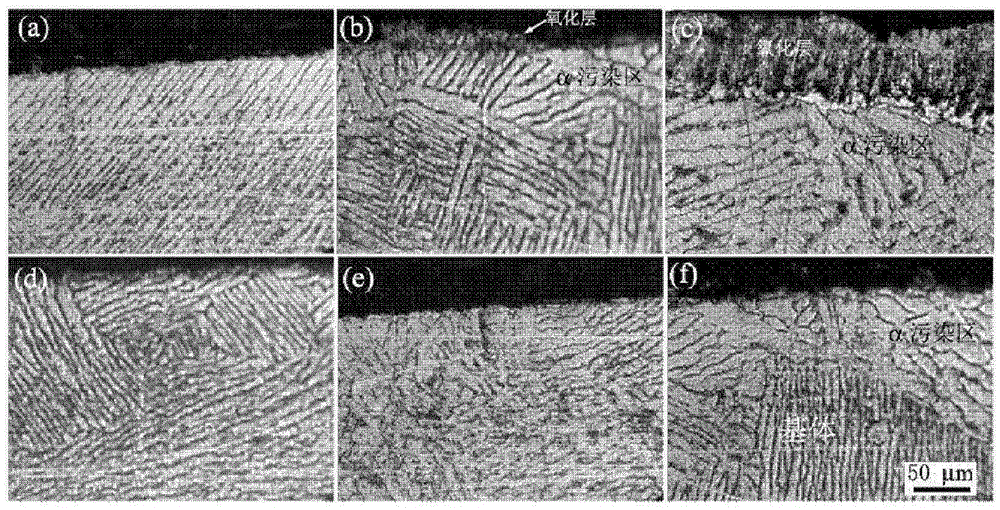

Examples

Embodiment 1

[0028] Embodiment 1 A kind of surface protective coating for thermal processing of titanium alloy

[0029] (1) Preparation method

[0030] 1) Water glass binder: take 10g of Na 2 SiO 3 9H 2 O was added to 190ml of distilled water, stirring constantly, until Na 2 SiO 3 9H 2 After O is completely dissolved, add 2g of sodium polyacrylate to the solution and keep stirring for about 10min. Let it stand for 10 hours, and it can be used after the sodium polyacrylate is completely dissolved in the solution.

[0031] 2) Industrial waste: Mix boron mud powder and waste glass powder at a mass ratio of 1:2. Boron mud is the waste of the long borax factory in Dashiqiao City, Liaoning Province (main components: diboron trioxide 7.96wt.%, aluminum oxide 1.26wt.%, magnesium oxide 36.02wt.%, silicon dioxide 30.43wt.%. %, calcium oxide 0.88wt.%), waste glass is ordinary silicate glass (Na 2 O CaO 6SiO 2 ). Firstly, the boron mud and waste glass are pulverized, ball milled, and passed...

Embodiment 2

[0037] Embodiment 2 A kind of surface protective coating for thermal processing of titanium alloy

[0038] (1) Preparation method

[0039] 1) Water glass binder: take 10g of Na 2 SiO 39H 2 O was added to 190ml of distilled water, stirring constantly, until Na 2 SiO 3 9H 2 After O is completely dissolved, add 2g of sodium polyacrylate to the solution and keep stirring for about 10min. Let it stand for 10 hours, and it can be used after the sodium polyacrylate is completely dissolved in the solution.

[0040] 2) Industrial waste: mix boron mud powder and waste glass powder at a mass ratio of 1:3; both boron mud and waste glass are wastes of enterprises. Firstly, the boron mud and waste glass are pulverized, ball milled, and passed through a 100-mesh sieve, and the under-sieve is taken to obtain boron mud powder and waste glass powder respectively.

[0041] 3) Auxiliary filler: mix the under-sieved calcium oxide sieved through 200 mesh, the under-sieved titanium dioxide s...

Embodiment 3

[0046] Embodiment 3 A kind of surface protective coating for thermal processing of titanium alloy

[0047] (1) Preparation method

[0048] 1) Water glass binder: take 10g of Na 2 SiO 3 9H 2 O was added to 190ml of distilled water, stirring constantly, until Na 2 SiO 3 9H 2 After O is completely dissolved, add 2g of sodium polyacrylate to the solution and keep stirring for about 10min. Let it stand for 10 hours, and it can be used after the sodium polyacrylate is completely dissolved in the solution.

[0049] 2) Industrial waste: Mix boron mud powder and waste glass powder at a mass ratio of 1:4.5. Boron mud is the waste of the long borax factory in Dashiqiao City, Liaoning Province (main components: diboron trioxide 7.96wt.%, aluminum oxide 1.26wt.%, magnesium oxide 36.02wt.%, silicon dioxide 30.43wt.%. %, calcium oxide 0.88wt.%), waste glass is ordinary silicate glass (Na 2 O CaO 6SiO 2 ). Firstly, the boron mud and waste glass are pulverized, ball milled, and pass...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com