Preparation method of yeast extract

A technology of yeast extract and yeast slime, which is applied in the field of improving the yield of yeast extract preparation, and can solve the problems of long time autolysis, high cost, and high price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

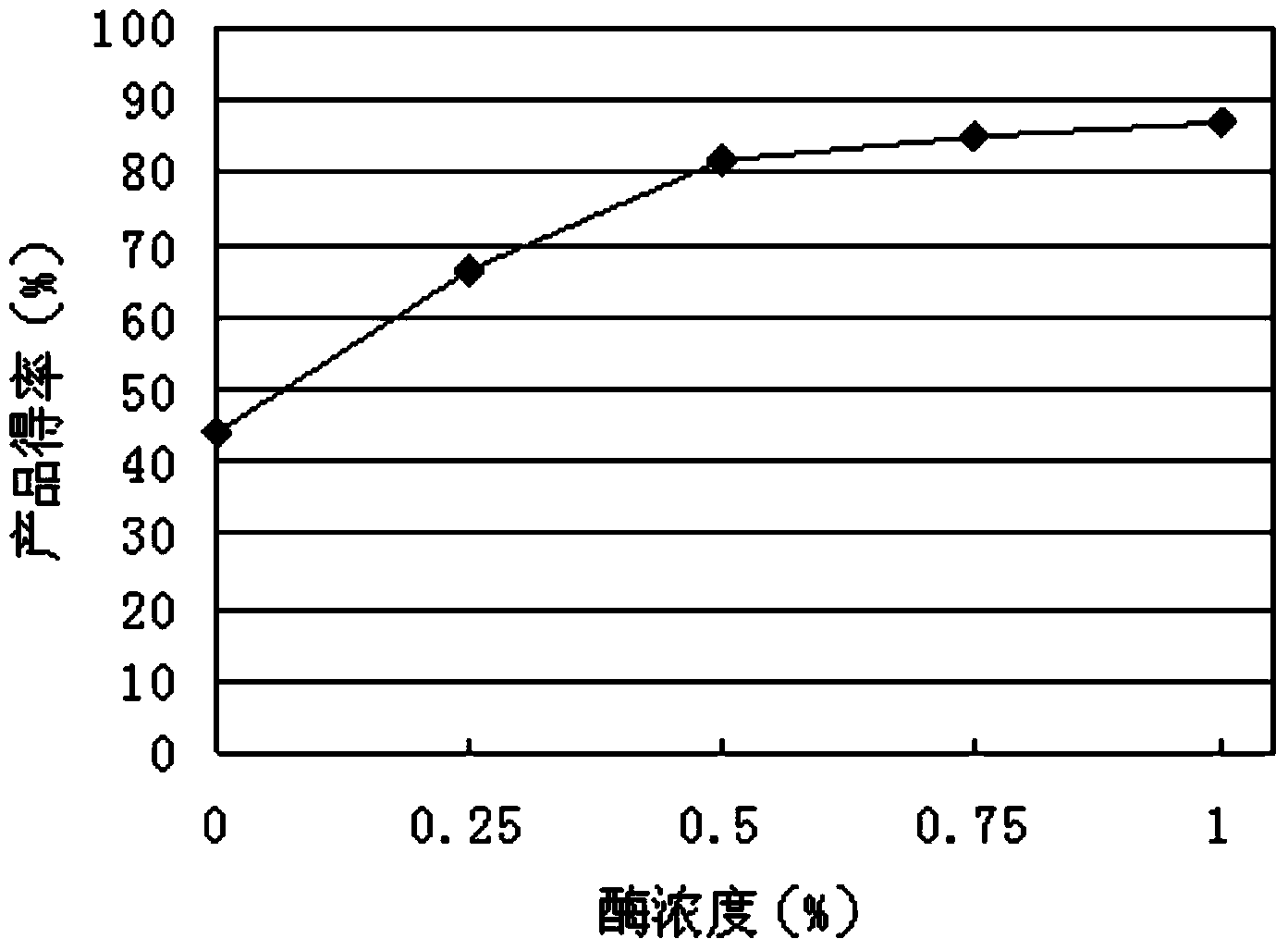

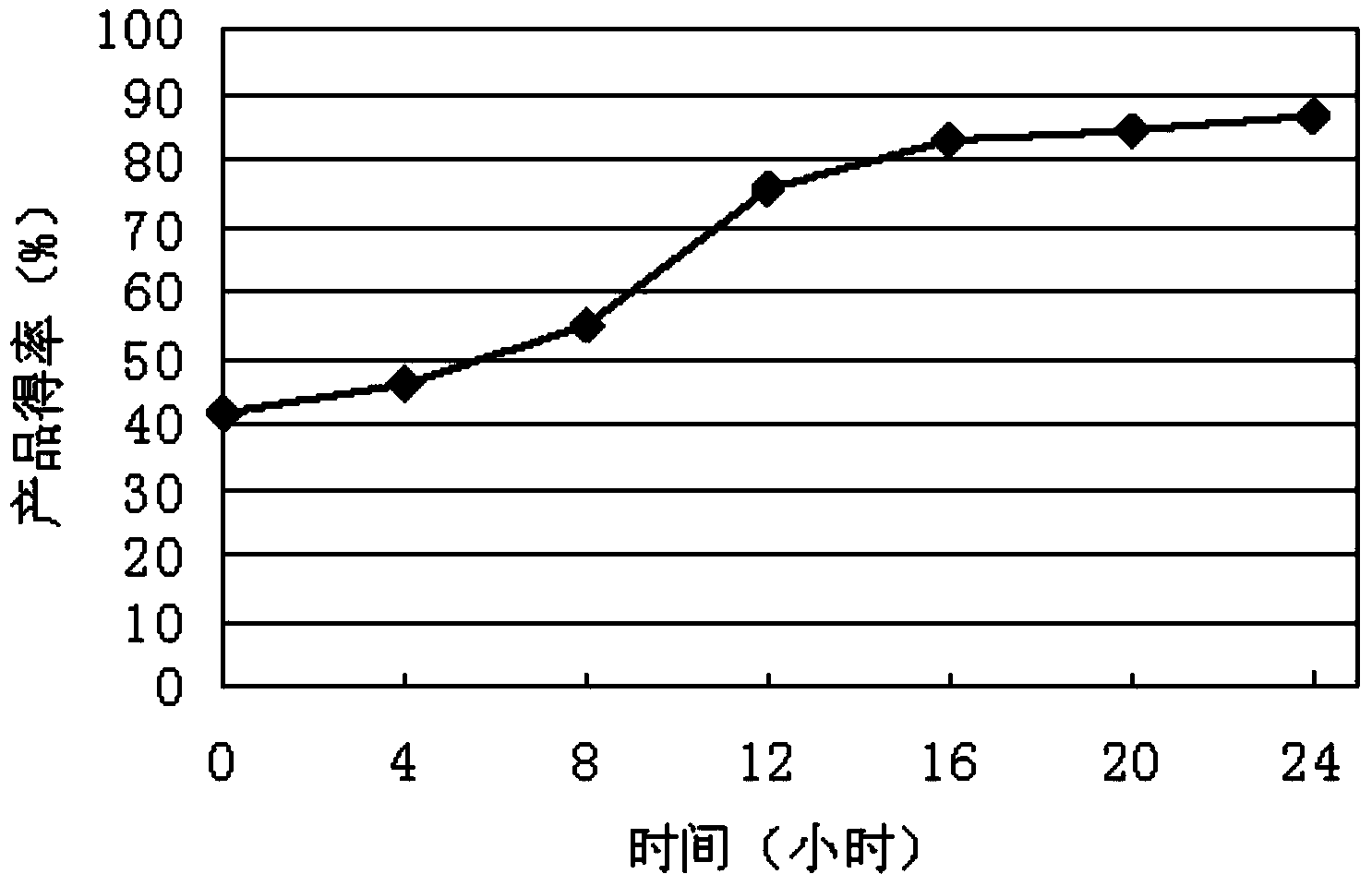

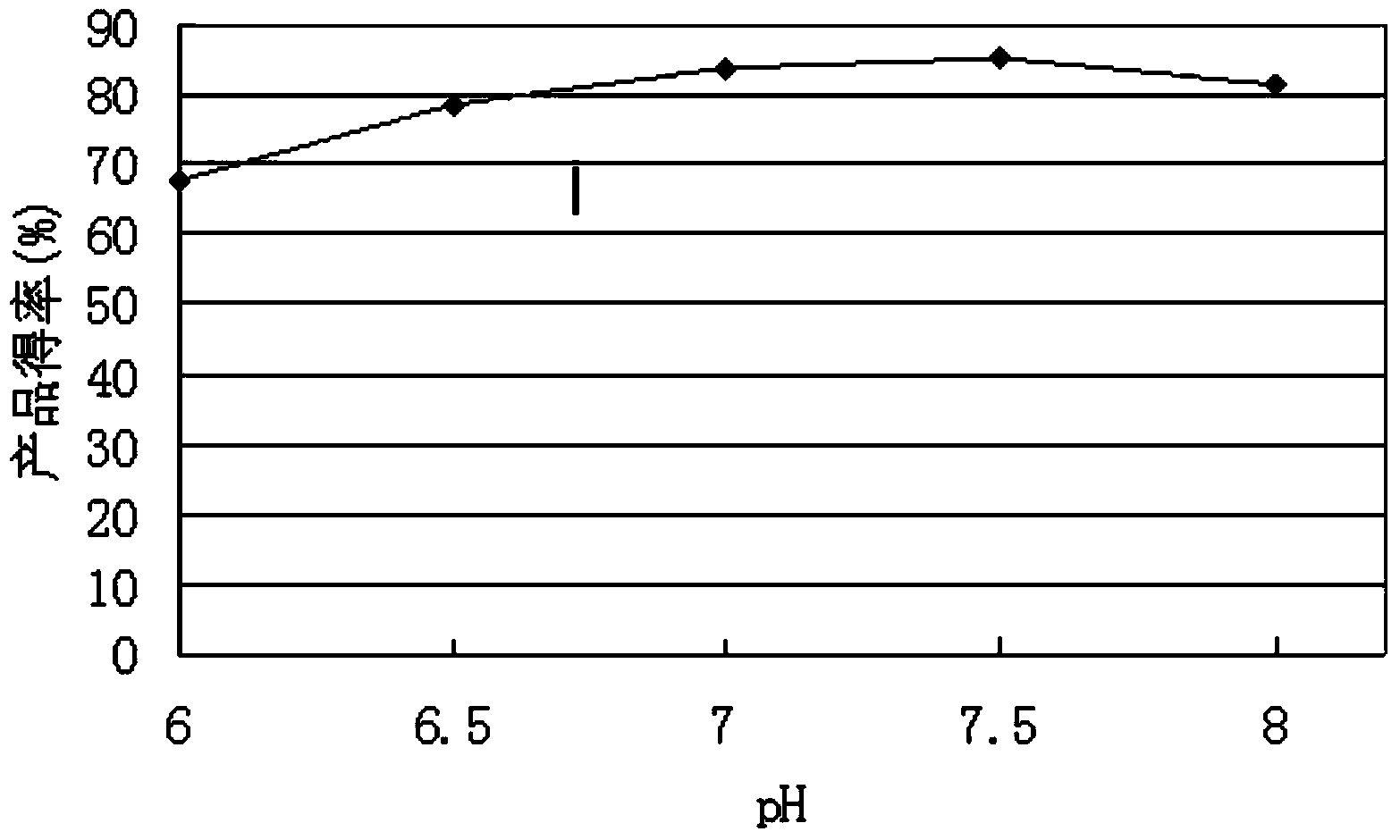

[0057] Embodiment 1, N-sugar amidase F enzymatic hydrolysis prepares yeast extract

[0058] Dilute 20 g of yeast slime to 100 ml with 50 mM pH7.5 sodium phosphate buffer, and suspend the yeast slime in sodium phosphate buffer; obtain 20% yeast liquid.

[0059] Add 0.5 g of N-glycosidase F (that is, the concentration is 0.5%) to the above 100 ml of 20% yeast liquid, and perform enzymatic hydrolysis at 37° C. and 150 rpm for 20 hours. Then add 1g of sodium chloride (that is, the concentration of sodium chloride is 1%), adjust the pH to 6.0 with 1M hydrochloric acid; autolyze at a constant temperature of 50°C for 20 hours. After constant temperature autolysis, inactivate the enzyme at 90°C for 20 minutes, then centrifuge at 3800rpm for 15 minutes, collect the supernatant, and dry the supernatant at 105°C to constant weight to obtain yeast extract.

[0060] Experiment 1. Calculation of Yeast Extract Yield

[0061] The collected supernatant was placed in an oven (105°C) to consta...

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight | aaaaa | aaaaa |

| molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com