Method for promoting methanogens to produce methane by utilizing dissimilatory metal reduction bacteria

A methanogenic bacteria and methane-producing technology, applied in the field of resource utilization of organic waste, can solve the problem of low methane production and achieve the effect of improving the conversion rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

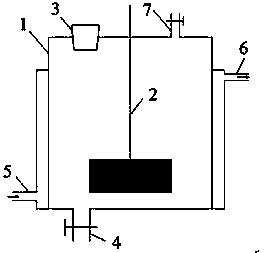

[0021] The present invention will be described in further detail below in conjunction with the accompanying drawings.

[0022] see figure 1 , the device that implements the method for the present invention adopts comprises adopting the fermentor 1 that materials such as organic glass, carbon steel or concrete are made, is provided with agitator 2 in fermentor 1, is respectively provided with advanced stage at the top of fermentor 1. The feed port 3 and the gas collection pipe 7 are provided with a sample outlet 4 at the bottom of the fermenter 1, and water inlet pipes 5 and outlet pipes 6 for cooling water (or heating water) are respectively provided at the lower and upper parts of the fermenter 1.

[0023] The dissimilatory metal-reducing bacteria were obtained by enriching the sedimentary sludge of paddy field as the inoculum, ferric oxide as the electron acceptor, and sodium acetate as the substrate.

[0024] Methanogens were obtained by enrichment screening using anaerob...

Embodiment 2

[0027] Anaerobic digested sludge was used as inoculum, ferric oxide as electron acceptor, and sodium acetate as substrate to obtain dissimilatory metal-reducing bacteria.

[0028] Methanogens were obtained by enrichment screening using anaerobic digested sludge as inoculum and glucose as substrate.

[0029] After centrifugation and concentration of the enriched dissimilatory metal-reducing bacteria (1×10 10 individuals / mL) and the inoculum of methanogenic bacteria obtained from enrichment screening and anaerobic digested sludge were added to the fermenter at a volume ratio of 3:3:4, and glucose (10 g / L) was used as the substrate37 °C fermentation produces methane. The gas production rate of methane is 2.3 L · L -1 · d -1 , the gas production rate increased by 15% compared with that without the addition of dissimilatory metal-reducing bacteria, and the conversion rate of glucose into methane reached 78%.

Embodiment 3

[0031] Inoculate microbial fuel cells (or microbial electrolytic cells) with seabed sediments as the inoculum, and enrich with sodium acetate as the substrate to obtain electroactive dissimilatory metal-reducing bacteria.

[0032] Methanogens were obtained by enrichment screening using anaerobic digested sludge as inoculum and glucose as substrate.

[0033] The enriched electroactive dissimilatory metal-reducing bacteria were centrifuged and concentrated (1×10 10 individuals / mL) and the inoculum of methanogenic bacteria obtained from enrichment screening and anaerobic digested sludge were added to the fermenter at a volume ratio of 3:3:4, and glucose (10 g / L) was used as the substrate37 °C fermentation produces methane. The gas production rate of methane is 2.4 L · L -1 · d -1 , the gas production rate increased by 20% compared with that without the addition of dissimilatory metal-reducing bacteria, and the conversion rate of glucose into methane reached 81%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com