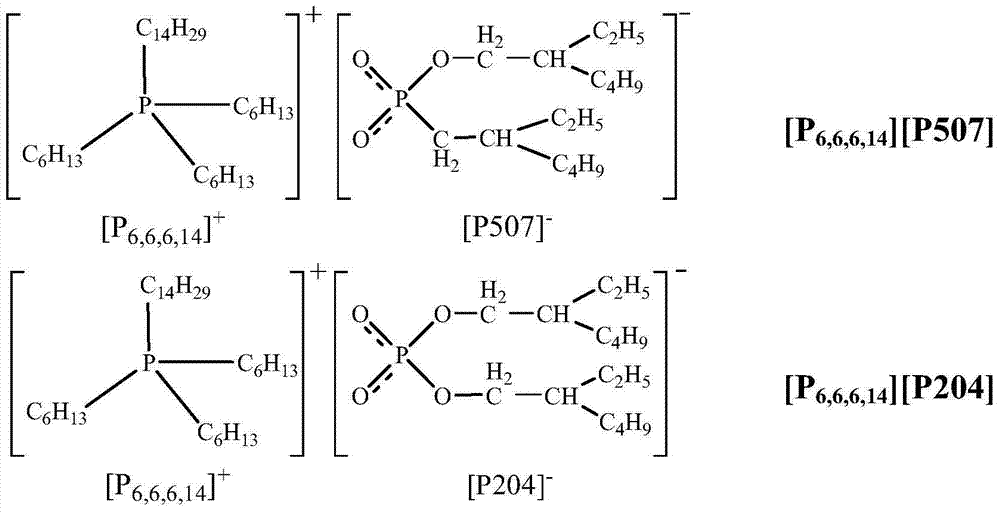

Method for recovering valuable metal element in waste phosphor by using phosphonium ionic liquid

A technology of ionic liquids and metal elements, which is applied in the field of green environmental protection and comprehensive resource utilization, can solve the problems of energy resource conservation and ecological environment protection, high acid consumption, and large energy consumption in the process, so as to improve the value of comprehensive utilization, The effect of low acid consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

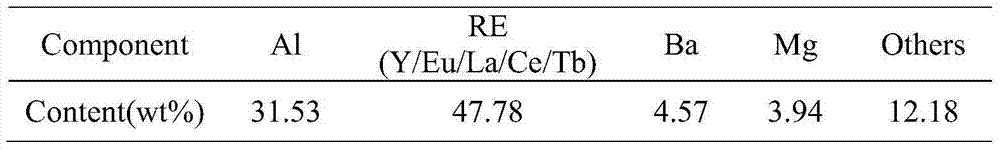

[0022] The original fluorescent powder was purchased from Xiamen Tongshida Company, and the components and contents of the fluorescent powder were measured by X-ray fluorescence spectroscopic analysis. The results are shown in Table 1.

[0023] Table 1 The main composition and content of rare earth three primary color phosphors

[0024]

Embodiment 2

[0026] Take 2g of the fluorescent powder obtained in Example 1 and 2g of NaOH solid into a nickel crucible, heat at 320°C for 2 hours, take out and cool to obtain a fluffy white powdery solid alkali melt, add 100ml of water and white powder to dissolve immediately, filter, Washing, after dissolving the obtained insolubles with nitric acid, the solution was left to stand for 0.5 hours and then filtered to obtain the original feed liquid, and the content of main metal ions such as rare earth ions and aluminum ions in the feed liquid was detected by atomic absorption spectroscopy to obtain rare earth ion The leaching rate of aluminum ions is 89.49%, while the leaching rate of aluminum ions is 28.80%.

Embodiment 3

[0028] Take 2g of the fluorescent powder obtained in Example 1 and 5g of NaOH solid into a nickel crucible, heat at 350°C for 4 hours, take out and cool to obtain a white solid block, add 100ml of water to dissolve the solid slowly, and accelerate the dissolution by ultrasonic. The solution is filtered, washed, and the obtained insolubles are dissolved with nitric acid, left to stand for 1 hour and filtered to obtain the original feed liquid, and the content of main metal ions such as rare earth ions and aluminum ions in the feed liquid is detected by atomic absorption spectrometry to obtain rare earth The leaching rate of ions was 65.03%, while that of aluminum ions was 37.94%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com