A silicon-based solar cell, its preparation method and preparation device, and its surface structure

A technology for solar cells and solar cell sheets, applied in the field of solar cells, can solve the problems of high cost, complicated operation, affecting the development of silicon-based solar cells, etc., and achieves improved quantum efficiency, improved light trapping effect, and increased photogenerated carriers. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

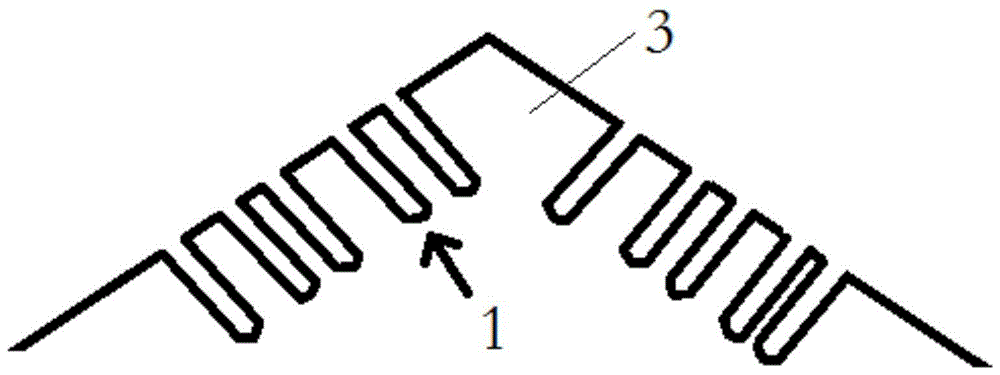

[0038] A method for preparing a silicon-based solar cell, comprising the steps of:

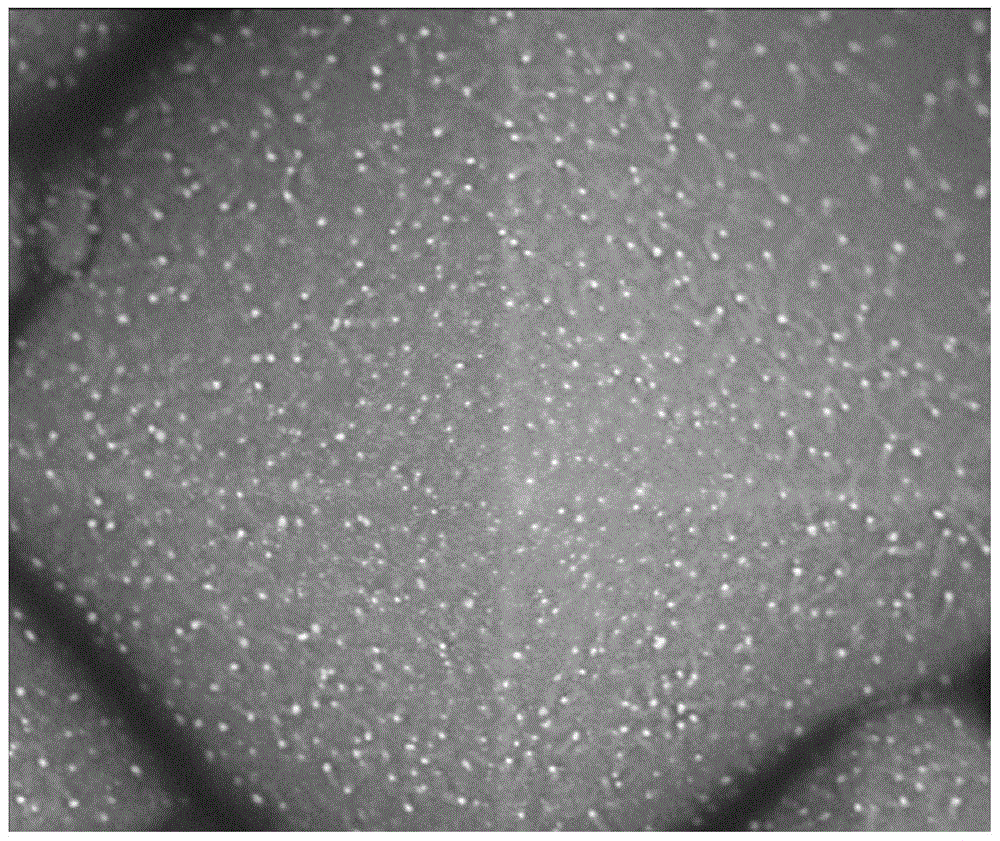

[0039] 1) Preparation of reaction solution: 0.01mol / L silver nitrate aqueous solution and a 0.007mol / L reducing reagent solution capable of reacting with silver nitrate aqueous solution to form silver elemental particles are prepared after mixing with a volume ratio of 1:50 to obtain a reaction solution Solution; In this example, sodium citrate solution was used as reducing agent solution.

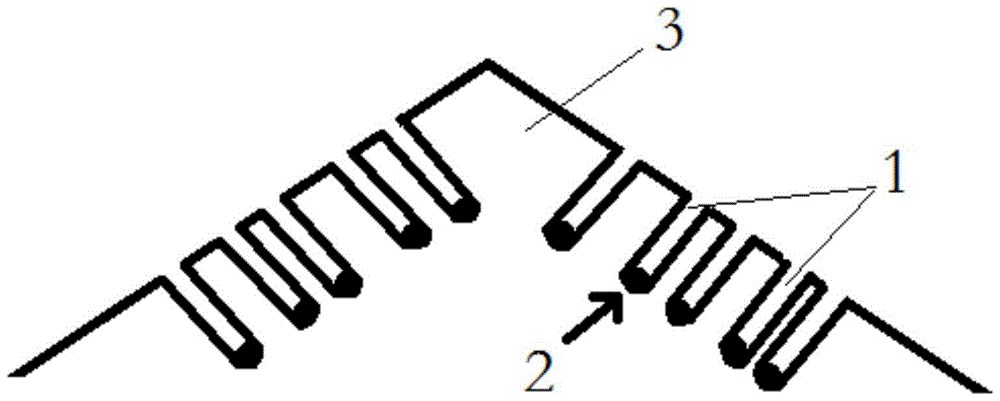

[0040] 2) Preparation of metal particles: heating the silicon-based solar cells to 100°C, using a heating device for heating the silicon-based solar cells 6, and a spraying device 5 for spraying the reaction solution onto the heated silicon-based solar cells , and a preparation device for a silicon-based solar cell of a container for containing an etching solution, spraying a reaction solution onto a heated silicon-based solar cell, and forming corresponding silver particles on the surface thereof;

[004...

Embodiment 2

[0047] A method for preparing a silicon-based solar cell, comprising the steps of:

[0048] 1) Preparation of reaction solution: 0.03mol / L gold tetrachlorate aqueous solution and a kind of reducing reagent solution of 0.035mol / L that can react with gold tetrachlorate aqueous solution to generate gold simple substance particles are mixed with a volume ratio of 1:300 Then prepare the reaction solution; in this example, sodium citrate solution is used as the reducing agent solution.

[0049] 2) Preparation of metal particles: heating the silicon-based solar cell to 200°C, using a heating device including a heating device 6 for heating the silicon-based solar cell, and a spraying device 5 for spraying the reaction solution onto the heated silicon-based solar cell , and a preparation device for a silicon-based solar cell of a container for containing an etching solution, spraying a reaction solution onto a heated silicon-based solar cell, and forming corresponding gold particles on...

Embodiment 3

[0053] A method for preparing a silicon-based solar cell, comprising the steps of:

[0054] 1) Preparation of reaction solution: 0.05 mol / L copper nitrate aqueous solution and a 0.05 mol / L reducing reagent solution capable of reacting with copper nitrate aqueous solution to form copper elemental particles are prepared by mixing at a volume ratio of 1:1 to obtain a reaction solution Solution; Adopt sodium borohydride solution as reducing agent solution in this example.

[0055] 2) Preparation of metal particles: heating the silicon-based solar cells to 400°C, using a heating device for heating the silicon-based solar cells 6, and a spraying device 5 for spraying the reaction solution onto the heated silicon-based solar cells , and a silicon-based solar cell manufacturing device for a container for containing an etching solution, spraying a reaction solution onto a heated silicon-based solar cell to form corresponding copper particles on the surface thereof;

[0056] 3) Etching...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com