Organic electroluminescence apparatus and preparation method thereof

An electroluminescent device and electroluminescent technology, which are applied in the manufacturing/processing of organic semiconductor devices, circuits, electrical components, etc., can solve the problem of poor performance of the light-emitting device, reducing the ability of electron injection into the organic light-emitting layer, poor light-emitting effect, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

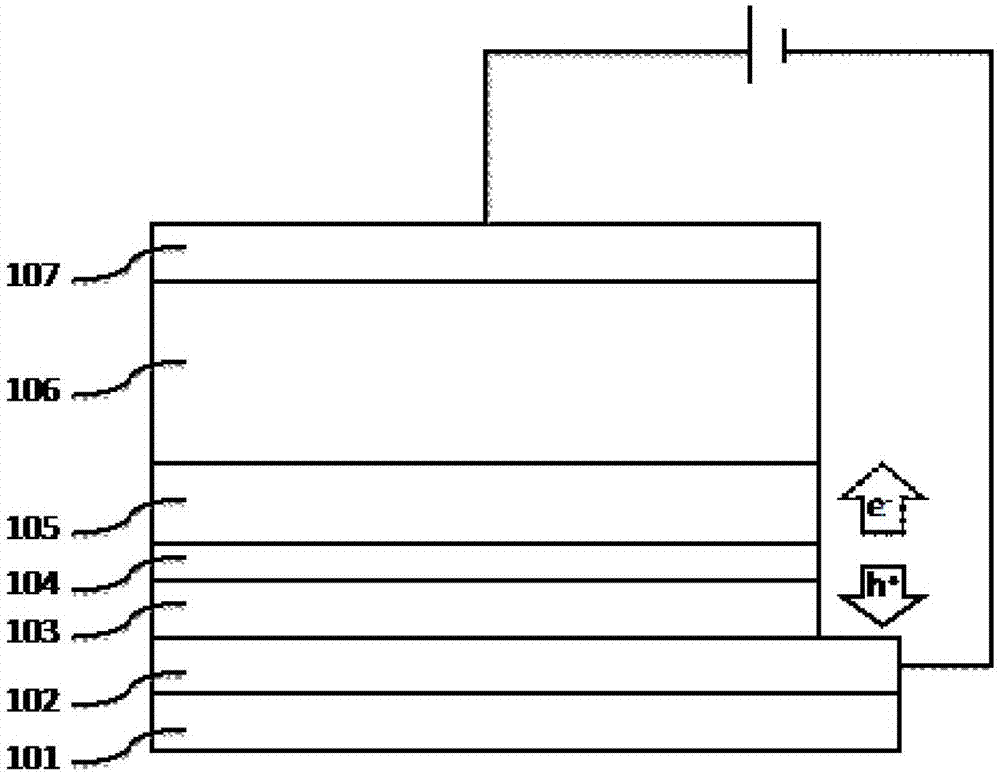

[0077] A method for preparing an organic electroluminescent device, comprising the steps of:

[0078] Place the glass substrate in deionized water containing detergent for ultrasonic cleaning. After cleaning, use isopropanol and acetone in ultrasonic treatment for 20 minutes, and then blow dry with nitrogen;

[0079] In a vacuum of 1×10 -4 In Pa's vacuum coating system, the indium tin oxide film (ITO) is prepared as the cathode on the surface of the glass substrate by sputtering at a speed of 0.1nm / s;

[0080] Through thermal evaporation process, in a vacuum of 1.0×10 -4 Evaporation of Au, Au and TiO in sequence under Pa and speed of 0.02nm / s 2 The pn junction layer is prepared by mixing the mixed material and Li according to the mass ratio of 1:4; then through the thermal evaporation process, in a vacuum of 1.0×10 -4 Under the conditions of Pa and speed 0.02nm / s, TPBi was evaporated sequentially, and C545T was doped to Alq according to the doping mass fraction of 15%. 3 T...

Embodiment 2

[0084] A method for preparing an organic electroluminescent device, comprising the steps of:

[0085]Place the glass substrate in deionized water containing detergent for ultrasonic cleaning. After cleaning, use isopropanol and acetone in ultrasonic treatment for 20 minutes, and then blow dry with nitrogen;

[0086] In a vacuum of 1×10 -5 In Pa's vacuum coating system, aluminum-zinc oxide film (AZO) was sputtered on the surface of the glass substrate at a speed of 1nm / s as the cathode;

[0087] Through thermal evaporation process, in a vacuum of 1.0×10 -5 Cu, Cu and Ta were sequentially evaporated under the conditions of Pa and speed 0.5nm / s 2 o 5 The pn junction layer is prepared by mixing the mixed material and Cs according to the mass ratio of 1:2; then through the thermal evaporation process, the vacuum degree is 1.0×10 -5 Under the conditions of Pa and speed 0.5nm / s, Bphen was evaporated sequentially, and DCJTB was doped to Alq according to the doping mass fraction of...

Embodiment 3

[0090] A method for preparing an organic electroluminescent device, comprising the steps of:

[0091] Place the glass substrate in deionized water containing detergent for ultrasonic cleaning. After cleaning, use isopropanol and acetone in ultrasonic treatment for 20 minutes, and then blow dry with nitrogen;

[0092] In a vacuum of 1×10 -3 In Pa's vacuum coating system, a gallium zinc oxide film (GZO) is prepared as a cathode on the surface of a glass substrate by sputtering at a speed of 0.5nm / s;

[0093] Through thermal evaporation process, in a vacuum of 1.0×10 -3 Under the conditions of Pa and speed 0.2nm / s, Ni, Ni and NiO are mixed according to the mass ratio of 1:5 to form a mixed material and Rb to prepare the pn junction layer; -3 Under the conditions of Pa and speed 0.2nm / s, TAZ, Rubrene, 2-TNATA, VOPc and Ni were sequentially evaporated to prepare electron transport layer, light emitting layer, hole transport layer, hole injection layer and anode, respectively.

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com