Letrozole troche and preparation method of letrozole troche

A technology of letrozole tablets and letrozole tablets, which can be used in pill delivery, pharmaceutical formulations, medical preparations of non-active ingredients, etc., can solve problems such as high cost, slow dissolution, and tediousness, and achieve energy and cost savings , Dissolution speed improvement, energy saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] Embodiment 1 letrozole tablet and preparation method thereof

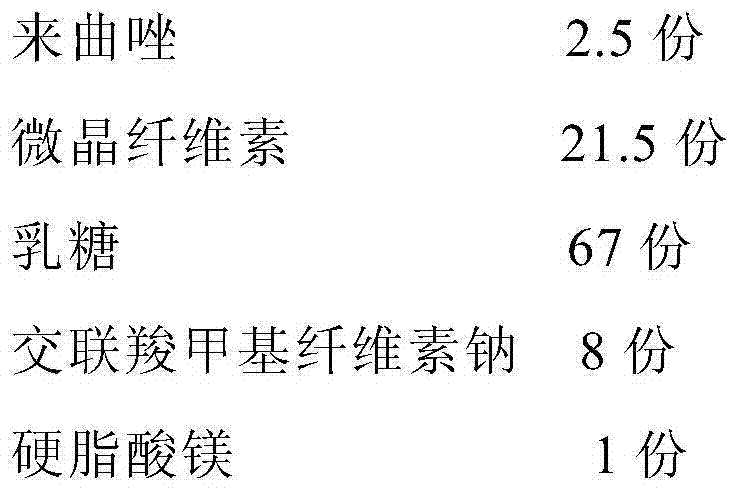

[0024] Letrozole tablet formulation:

[0025]

[0026] Preparation:

[0027] (1) Take the raw drug of letrozole, and use a high-speed drug pulverizer to pulverize it for 3 minutes until the particle size d (0.9) is 80 μm. After pulverization, use a Malvern laser particle size analyzer to detect the particle size. The results are shown in Table 2;

[0028] (2) Mixing the pulverized letrozole raw material in the above weight ratio with lactose for 30 minutes;

[0029] (3) Add microcrystalline cellulose and croscarmellose sodium in the above weight ratio, and mix for 90 minutes;

[0030] (4) Add magnesium stearate in the above weight ratio and mix for 10 minutes;

[0031] (5) Compress the mixed powder into tablets on a tablet press;

[0032] (6) Coat the plain tablets on a high-efficiency coating machine, and pack the finished products after the coated tablets pass the inspection.

Embodiment 2

[0033] Embodiment 2 letrozole tablet and preparation method thereof

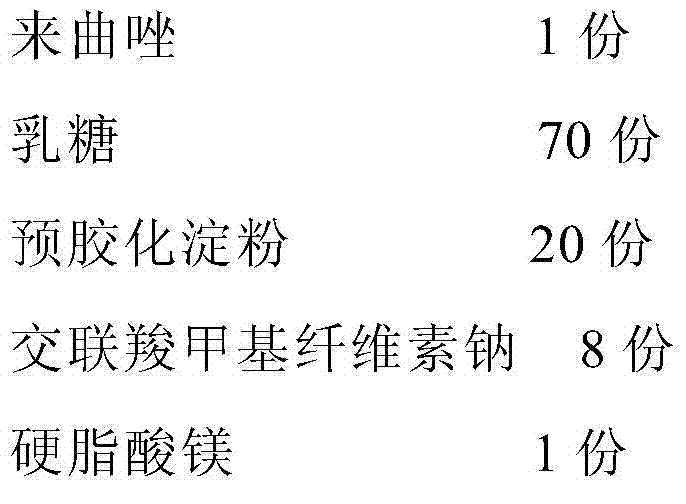

[0034] Letrozole tablet formulation:

[0035]

[0036] Preparation:

[0037] (1) Take the letrozole raw material, pulverize it with a ball mill for 15 minutes, and pulverize it until the particle size d (0.9) is 62 μm. After pulverization, use a Malvern laser particle size analyzer to detect the particle size. The results are shown in Table 2;

[0038] (2) Mixing the pulverized letrozole raw material in the above weight ratio with lactose for 30 minutes;

[0039] (3) Add the pregelatinized starch and croscarmellose sodium in the above weight ratio, and mix for 90 minutes;

[0040] (4) Add magnesium stearate in the above weight ratio and mix for 10 minutes;

[0041] (5) Compress the mixed powder into tablets on a tablet press;

[0042] (6) Coat the plain tablets on a high-efficiency coating machine, and pack the finished products after the coated tablets pass the inspection.

Embodiment 3

[0043] Embodiment 3 letrozole tablet and preparation method thereof

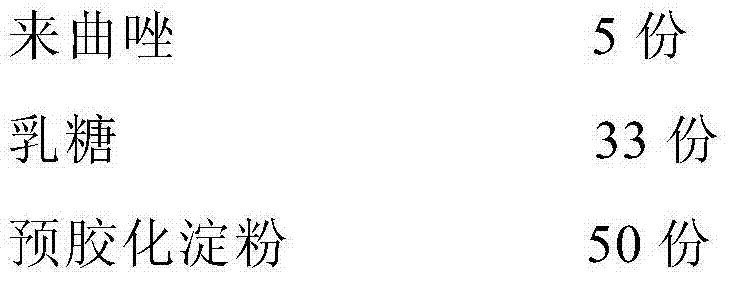

[0044] Letrozole tablet formulation:

[0045]

[0046]

[0047] Preparation:

[0048] (1) Take the letrozole raw material and pulverize it with a jet mill with a pulverization pressure of 6Mpa until the particle size d (0.9) is 36 μm. After pulverization, use a Malvern laser particle size analyzer to detect the particle size. The results are shown in Table 2;

[0049] (2) Mixing the pulverized letrozole raw material in the above weight ratio with lactose for 30 minutes;

[0050] (3) Add the pregelatinized starch and croscarmellose sodium in the above weight ratio, and mix for 90 minutes;

[0051] (4) Add magnesium stearate in the above weight ratio and mix for 10 minutes;

[0052] (5) Compress the mixed powder into tablets on a tablet press;

[0053] (6) Coat the plain tablets on a high-efficiency coating machine, and pack the finished products after the coated tablets pass the inspection.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com