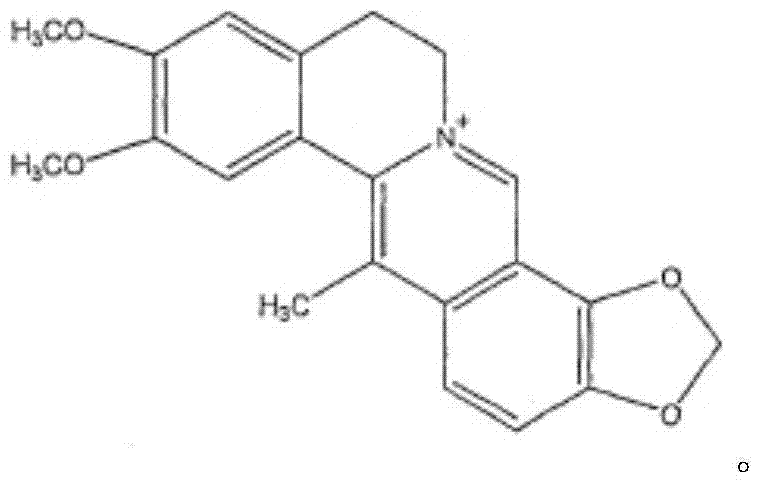

Dehydrocavidine-containing pharmaceutical composition and preparation method thereof

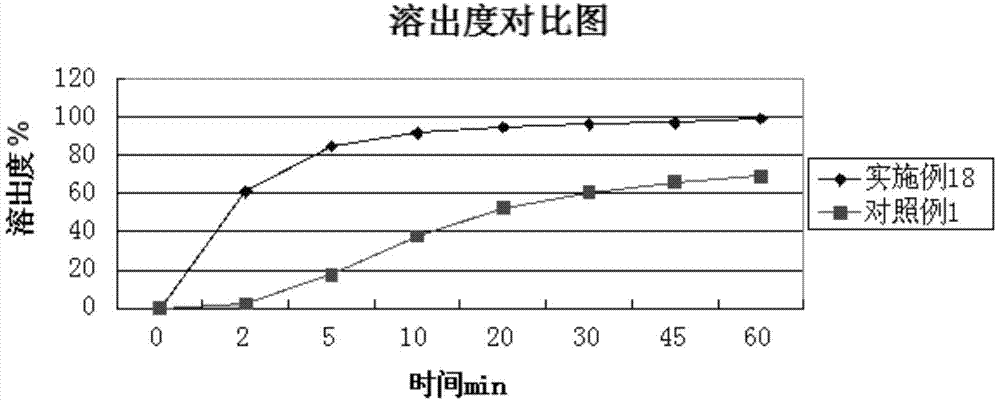

A technology of dehydrocarvetin and composition, which is applied in the direction of medical preparations containing active ingredients, medical preparations with non-active ingredients, and pharmaceutical formulas, and can solve the problems of slow dissolution rate and collapse of common dehydrocarvetin preparations. Solve problems such as slow solution and failure to reach therapeutic dosage, and achieve the effects of improved dissolution rate, good stability, portability, and good compliance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

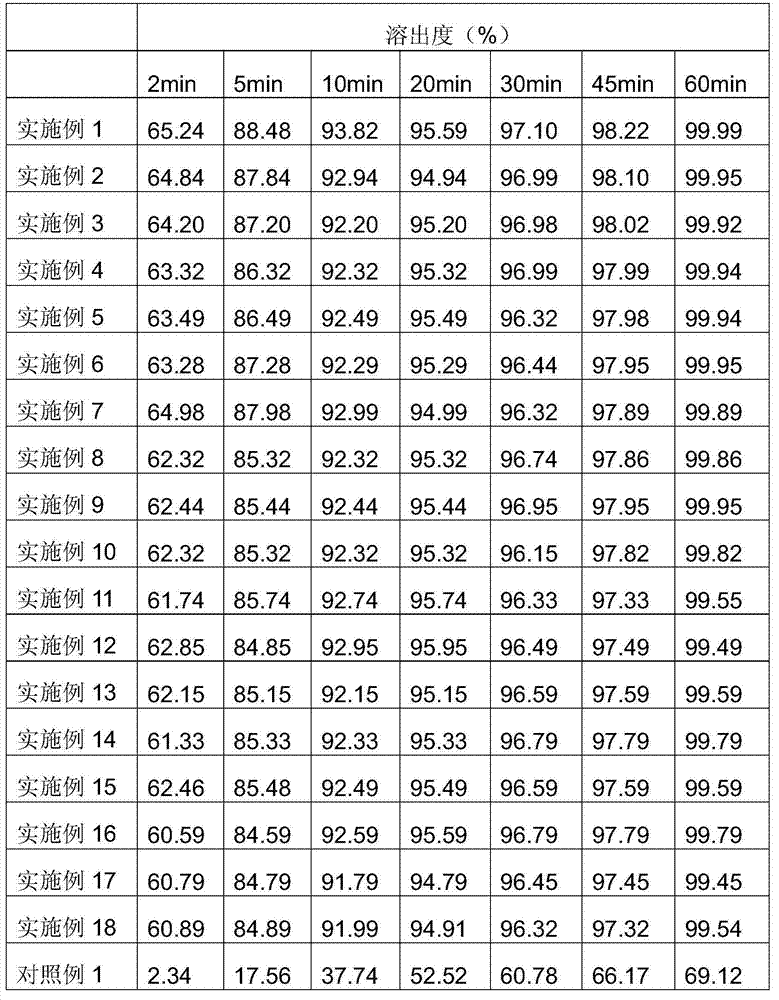

Examples

Embodiment 1

[0049] Weigh 5 mg of dehydrocarvetin, 15 mg of precross-linked starch, 10 mg of microcrystalline cellulose, 0.1 mg of sodium lauryl sulfate, 5 mg of crospovidone, 1 mg of croscarmellose sodium, and appropriate amount of sweetness agent, pass through 80 mesh sieve, mix evenly, add dropwise 5% polyvinylpyrrolidone aqueous solution to make soft material, pass through 24 mesh sieve to granulate, dry the granules at 45-80°C, the moisture reaches 0.5-10%, granulate, add Magnesium stearate 0.1 mg, mixed evenly, compressed into tablets.

Embodiment 2

[0051] Weigh 5 mg of dehydrocarvetin, 15 mg of precross-linked starch, 10 mg of microcrystalline cellulose, 0.1 mg of sodium lauryl sulfate, 5 mg of crospovidone, 1 mg of croscarmellose sodium, and appropriate amount of sweetness agent, pass through 80 mesh sieve, mix evenly, add dropwise 5% polyvinylpyrrolidone aqueous solution to make soft material, pass through 24 mesh sieve to granulate, dry the granules at 45-80°C, the moisture reaches 0.5-10%, granulate, add Micropowder silica gel 0.1mg, mixed evenly, compressed into tablets.

Embodiment 3

[0053] Weigh 25 mg of dehydrocarvetin, 15 mg of precrossed starch, 50 mg of lactose, 0.5 mg of sodium lauryl sulfate, 5 mg of crospovidone, 10 mg of croscarmellose sodium, appropriate amount of sweetener, over 80 mesh sieve, mix evenly, dropwise add 5% polyvinylpyrrolidone aqueous solution to make soft material, pass through 24 mesh sieve to granulate, dry the granules at 45-80°C, the moisture reaches 0.5-10%, granulate, add stearic acid Magnesium 1.2mg, mixed evenly, tableted.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com