Preparation method of mo/molecular sieve supported catalyst

A supported catalyst and molecular sieve technology, applied in the field of catalysis, can solve the problems of poor stability, low yield of total aromatics, low benzene selectivity, etc., and achieve the effects of easy scale-up, improved methane conversion rate, and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

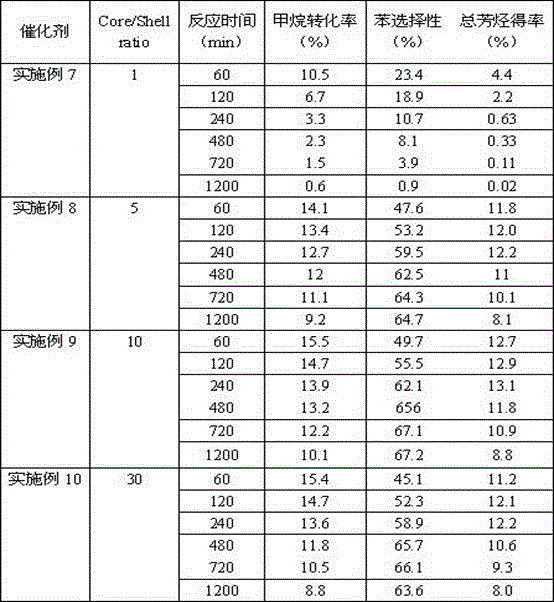

Examples

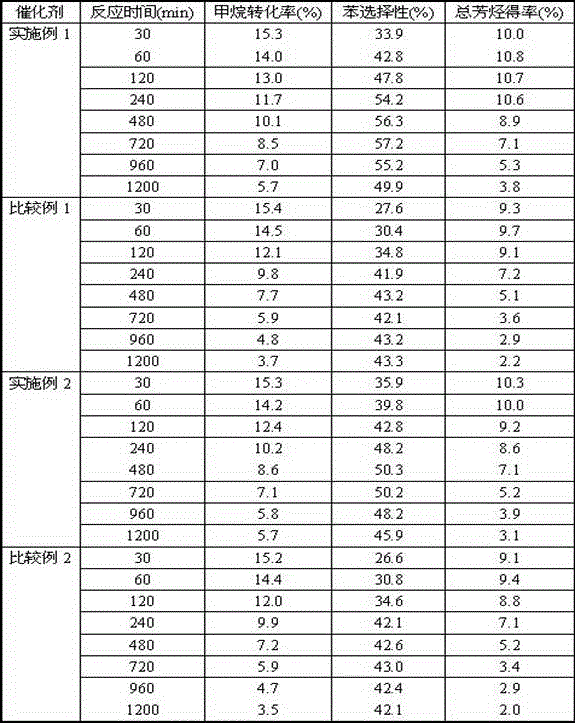

Embodiment 1

[0019] HZSM-5 molecular sieve (SiO 2 / Al 2 o 3 The molar ratio is 50) As the Mo species organic precursor and carrier of the Mo / zeolite-supported catalyst, the Mo / HZSM-5 catalyst of Example 1 was prepared, wherein the weight percentage of Mo was 4%. The preparation method and reaction evaluation steps of the catalyst are as follows:

[0020] 1) The catalyst preparation method of embodiment 1:

[0021] (a) Molecular sieve carrier organic solvent pretreatment: 20 g SiO 2 / Al 2 o 3 HZSM-5 molecular sieve with a molar ratio of 50 was stirred and mixed with 100 ml methanol to form a suspension, and 80 o After condensing and refluxing for 2 h under the condition of C, the solvent was removed by suction filtration and placed in a vacuum oven for 80 o C is vacuum-dried to obtain a molecular sieve carrier pretreated with an organic solvent;

[0022] (b) Preparation of Mo / molecular sieve supported catalyst by impregnation: Weigh 8.53 g molybdenum naphthenate with Mo content of 1...

Embodiment 2

[0032] SiO 2 / Al 2 o 3 The HZSM-5 molecular sieve with a molar ratio of 50 was used as the carrier without organic solvent pretreatment, and the Mo species organic precursor was directly supported to prepare the Mo / HZSM-5 catalyst, where the weight percentage of Mo was 4%. Than the preparation process and reaction evaluation of the Mo / HZSM-5 catalyst of embodiment 2:

[0033] 1) The catalyst preparation method of embodiment 2:

[0034] Weighed 8.53 g of molybdenum naphthenate with a Mo content of 1.0 wt.% as the organic precursor of Mo species, dissolved it in 20 ml of toluene to form a Mo-containing impregnation solution, and then directly added 2 g of SiO 2 / Al 2 o 3 HZSM-5 molecular sieve with a molar ratio of 50, ultrasonically dispersed for 5 min, 30 oC Under the conditions, rotate and stir at a rate of 300 rpm for 10 h, and distill off the solvent under reduced pressure, in an air atmosphere, with 5 o C / min heating rate from room temperature to 350 oC , after m...

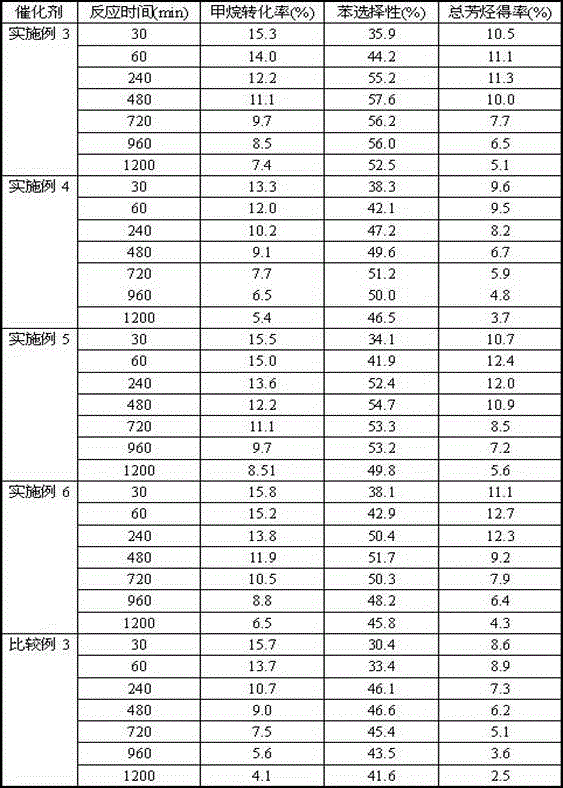

Embodiment 3

[0048] HZSM-5 molecular sieve (SiO 2 / Al 2 o 3 The molar ratio is 25) As the Mo species organic precursor and carrier of the Mo / zeolite-supported catalyst, the Mo / HZSM-5 catalyst of Example 3 was prepared, wherein the weight percentage of Mo was 6%. The preparation method and reaction evaluation steps of the catalyst are as follows:

[0049] 1) The catalyst preparation method of embodiment 3:

[0050] (a) Molecular sieve carrier organic solvent pretreatment: 20 g SiO 2 / Al 2 o 3 HZSM-5 molecular sieve with a molar ratio of 25 was stirred and mixed with 100 ml acetone to form a suspension, 70 o After condensing and refluxing for 4 h under the condition of C, the solvent was removed by suction filtration and placed in a vacuum oven for 80 o C is vacuum-dried to obtain a molecular sieve carrier pretreated with an organic solvent;

[0051] (b) Preparation of Mo / molecular sieve supported catalyst by impregnation: Weigh 0.444 g molybdenum acetylacetonate as the organic precu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com