Novel preparation method of titanium dioxide-cellulose composite material

A composite material, titanium dioxide technology, applied in the field of preparation of nano-composite materials, can solve the problems of large energy consumption, complex preparation process, and decrease in specific surface area, and achieve the effects of convenient recycling, strong catalytic performance, and convenient preparation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0017] The preparation method of titanium dioxide-cellulose composite material in the present embodiment comprises the following steps:

[0018] (1) Drop 1ml of titanium tetrachloride into liquid nitrogen, then slowly add deionized water into it, wherein the mass ratio of deionized water to titanium tetrachloride is 50:1, and then stir it evenly with ultrasonic to prepare the precursor solution.

[0019] (2) Weigh 0.2 g of cellulose, add it to the precursor solution prepared in step (1) and mix it under stirring conditions, wherein the mass ratio of cellulose and titanium tetrachloride is controlled at 10:1, and then The mixed solution obtained after mixing was transferred to a three-necked flask, stirred and heated at 30° C. for 72 hours to obtain a heated reaction solution.

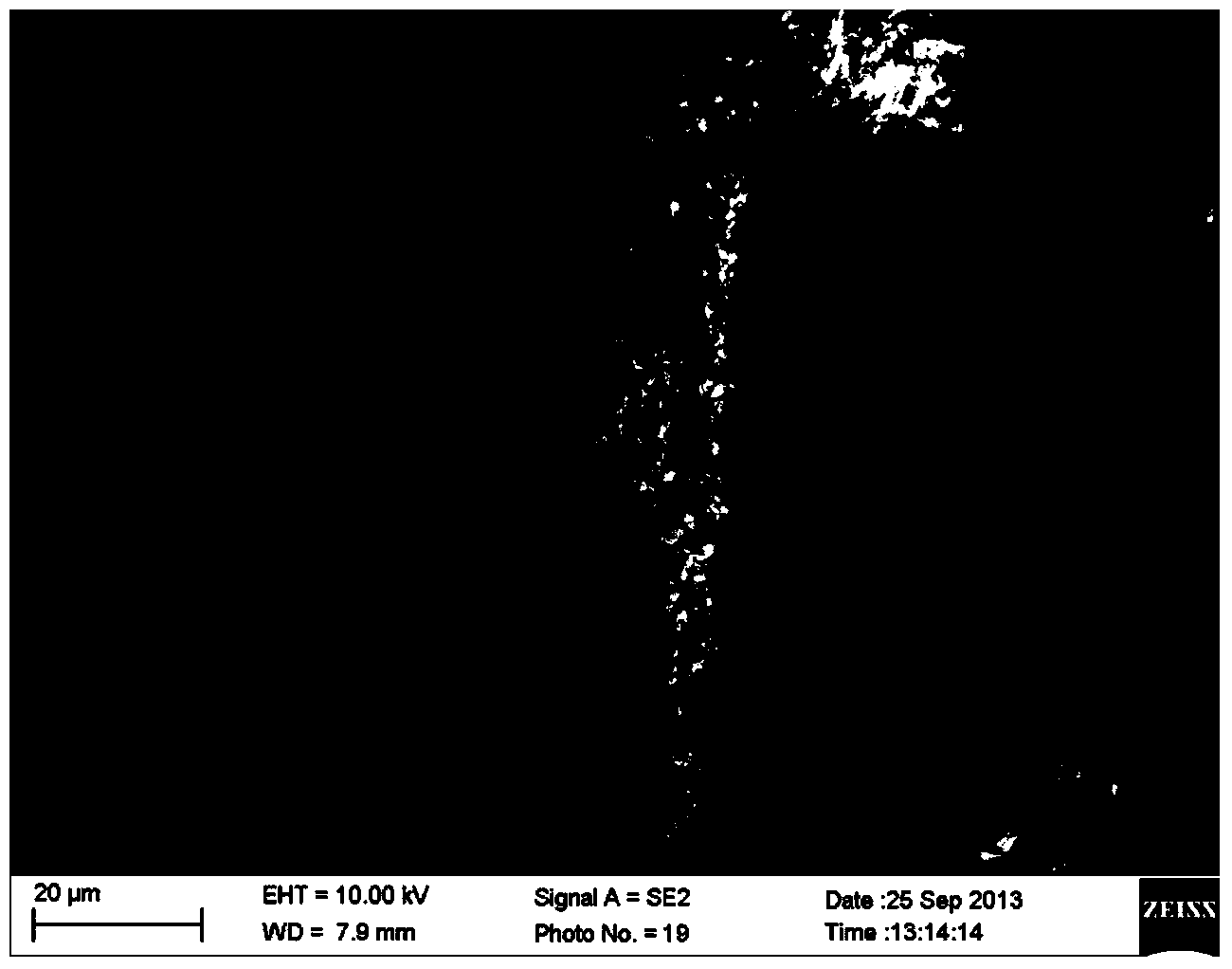

[0020] (3) The heated reaction solution obtained in step (2) was centrifugally cleaned, and then dried in an oven at 40° C. to obtain a titanium dioxide-cellulose composite material. The scanning elec...

Embodiment 2

[0023] The preparation method of titanium dioxide-cellulose composite material in the present embodiment comprises the following steps:

[0024] (1) Drop 1ml of titanium tetrachloride into liquid nitrogen, then slowly add deionized water into it, wherein the mass ratio of deionized water to titanium tetrachloride is 60:1, and then stir it evenly with ultrasonic to prepare the precursor solution.

[0025] (2) Weigh 0.2 g of cellulose, add it to the precursor solution prepared in step (1) and mix it under stirring conditions, wherein the mass ratio of cellulose and titanium tetrachloride is controlled at 40:1, and then After mixing, the resulting mixture was transferred to a three-necked flask, stirred and heated at 70° C. for 24 hours to obtain a heated reaction solution.

[0026] (3) The heated reaction solution obtained in step (2) was centrifugally cleaned, and then dried in an oven at 80° C. to obtain a titanium dioxide-cellulose composite material.

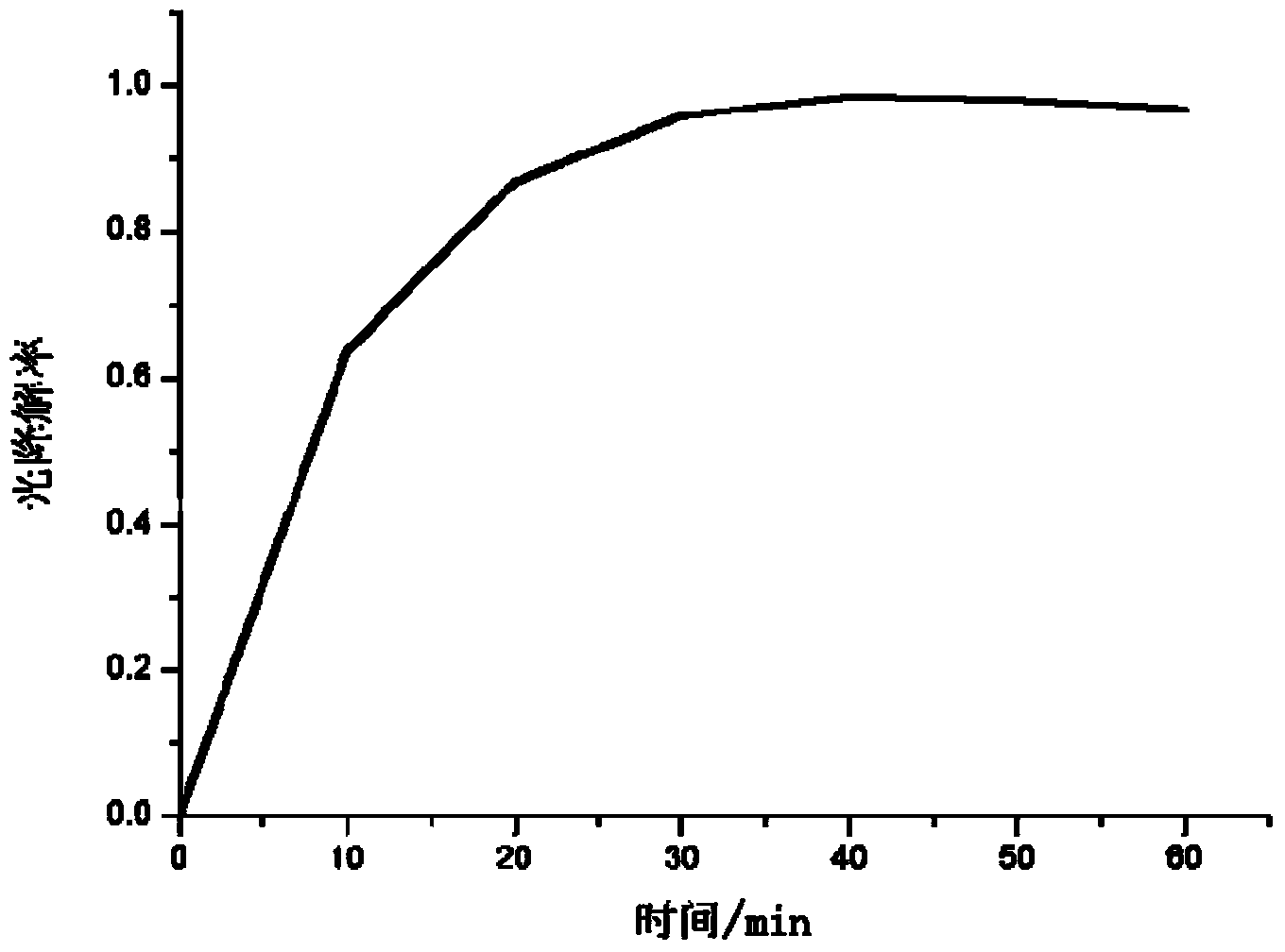

[0027] Take 0.15g of...

Embodiment 3

[0029] The preparation method of titanium dioxide-cellulose composite material in the present embodiment comprises the following steps:

[0030] (1) Drop 1.5ml of titanium tetrachloride into liquid nitrogen, then slowly add deionized water into it, wherein the mass ratio of deionized water to titanium tetrachloride is 70:1, and then ultrasonically stir evenly to obtain a precursor body solution.

[0031] (2) Weigh 0.2 g of cellulose, add it to the precursor solution prepared in step (1) and mix it under stirring conditions, wherein the mass ratio of cellulose and titanium tetrachloride is controlled to be 80:1, and then After mixing, the resulting mixture was transferred to a three-necked flask, stirred and heated at 80° C. for 12 hours to obtain a heated reaction solution.

[0032] (3) The heated reaction solution obtained in step (2) was centrifugally cleaned, and then dried in an oven at 80° C. to obtain a titanium dioxide-cellulose composite material.

[0033] Take 0.15g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com