PTFE (Poly Tetra Fluoro Ethylene) glass fiber single-surface composite material

A technology of glass fiber and composite materials, applied in the direction of glass/slag layered products, synthetic resin layered products, chemical instruments and methods, etc., can solve the problems of low service life, high hardness, poor high temperature resistance, etc., and achieve service life Long-lasting, softness-improved, and easy-to-use effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

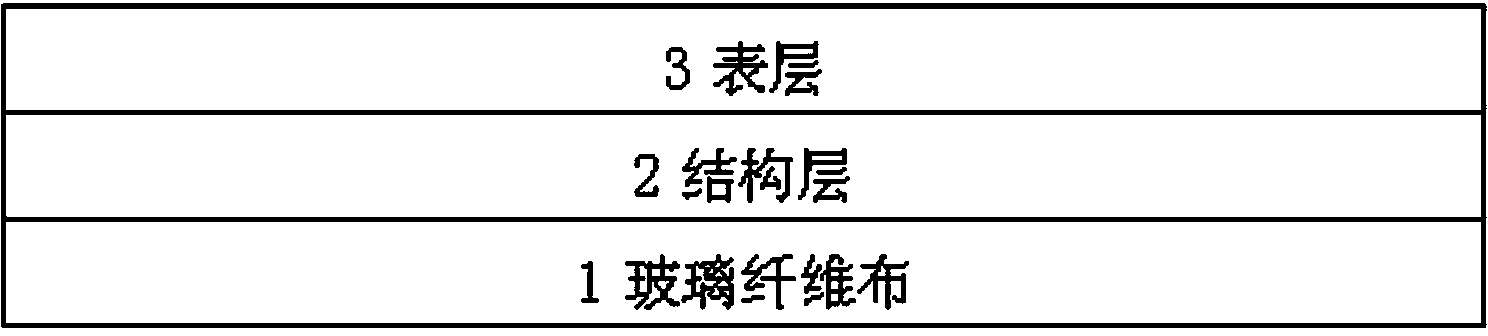

[0012] The present invention will be further described below in conjunction with accompanying drawing.

[0013] figure 1 As shown, a PTFE fiberglass single-sided composite material includes a glass fiber substrate layer 1, a structural layer 2 and a polytetrafluoroethylene surface layer 3. The glass fiber substrate layer 1 is sequentially laminated with a structural layer 2 and a polytetrafluoroethylene surface layer 3. The glass fiber substrate 1 is a glass fiber cloth after singeing and coloring treatment, and the structural layer 2 is made of 93% polytetrafluoroethylene emulsion. , 6% hydrophilic nano-silica, 2% polyacrylate acrylic acid organic thickener mixed dip-coating; the thickness of the glass fiber substrate layer is 0.25㎜-0.75㎜; the thickness of the structural layer is 0.05㎜-0.20㎜ ; PTFE surface thickness 0.01㎜-0.05㎜.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com