Preparation method of stable graphene colloidal dispersion liquid

A technology of olefin colloid and dispersion liquid, which is applied in the field of graphene preparation to achieve good stability, easy control of the reaction process, and small particles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0048] A kind of preparation method of graphene dispersion liquid, comprises following processing step:

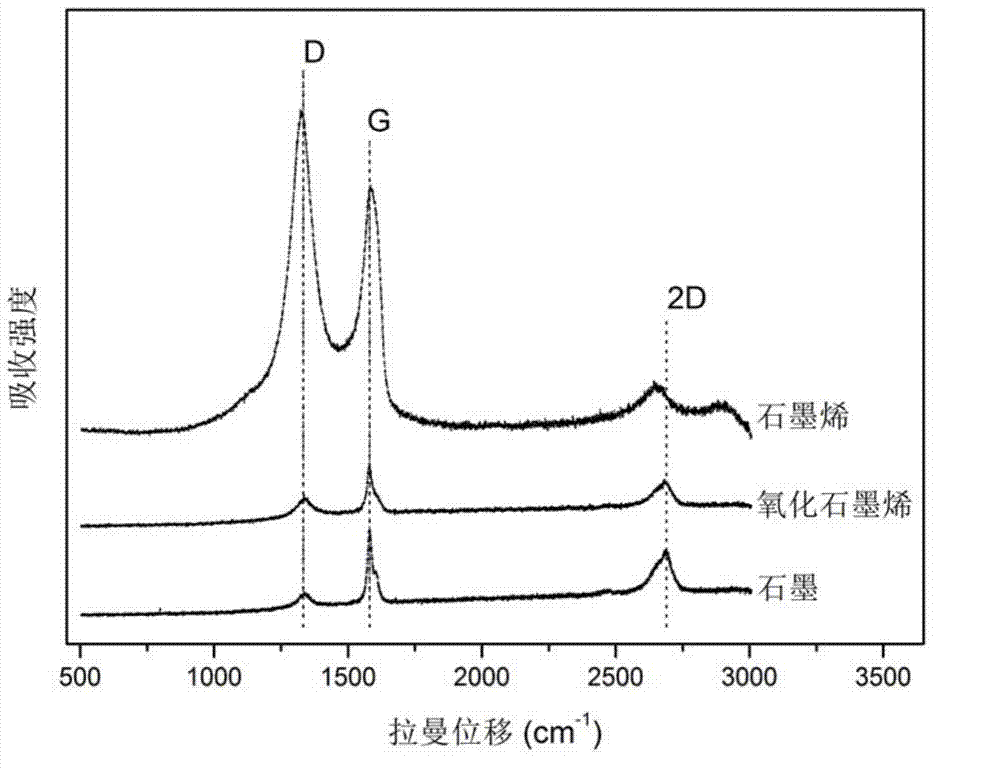

[0049] Mix 1g, 99.85wt% graphite powder with 23mL, 98wt% H 2 SO 4 Mix in a 250mL beaker and stir at room temperature for 24 hours; add 100mg, 99.0wt% NaNO to the beaker in a 40°C water bath 3 And stir for 5min to fully dissolve it. Slowly add 1500mg, 99.5wt% KMnO into the cup 4 , About 20min to complete the addition, control the reaction temperature below 5°C, and stir for 30min. Add 3 mL of distilled water to the beaker, wait for 5 minutes, then add 3 mL of distilled water, wait for 5 minutes, then add 40 mL of distilled water, and stir for 15 minutes. Stop the water bath and add 140 mL of distilled water and 10 mL of 30 wt% H to the beaker 2 o 2 Stir at room temperature for 5 min to terminate the reaction. Use a centrifuge to centrifuge at 10000r / min for 4min, wash with 5wt% HCl, and repeat twice. Then use centrifuge 8000r / min centrifuge 4min, wash three times wi...

Embodiment 2

[0051] A preparation method of a stable graphene dispersion, comprising the following processing steps:

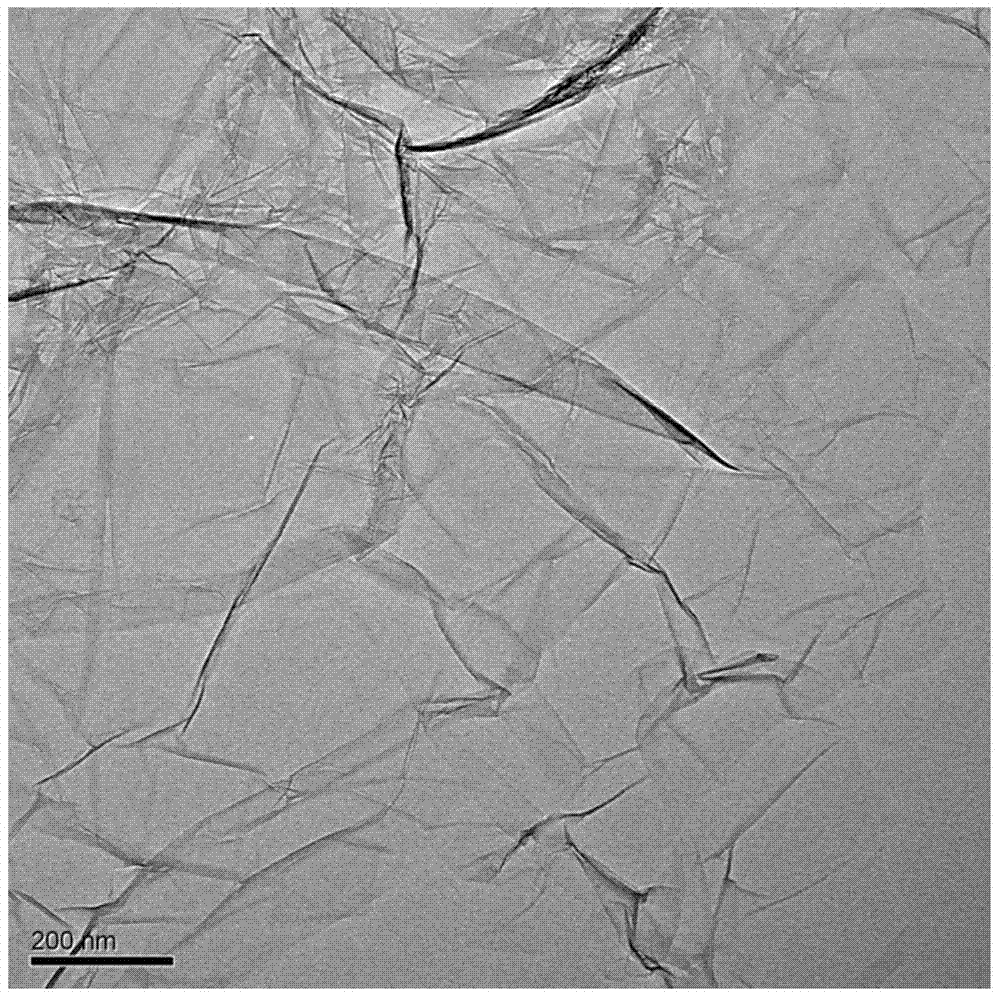

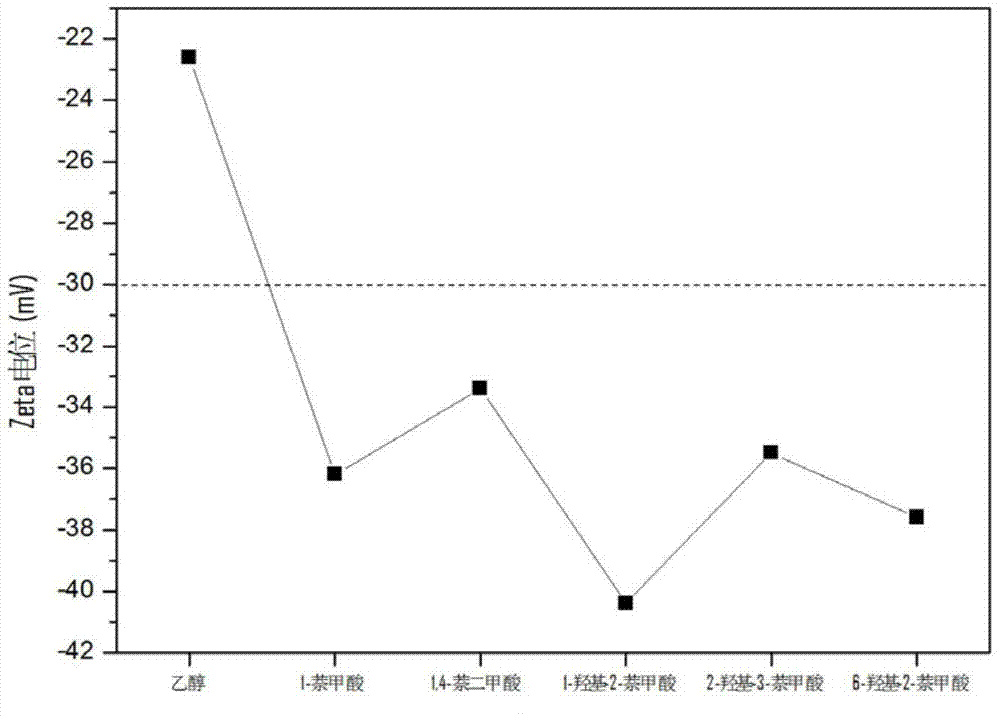

[0052] Dissolve the graphene in Example 1 in 100mL, 99.7wt% ethanol, 70kHz ultrasound for 30min to peel and disperse, centrifuge at 12000r / min for 5min, wash with distilled water 2-3 times, and wash away residual ethanol. Disperse the precipitate in 100mL distilled water, ultrasonicate at 70kHz for 30min, and centrifuge at 10000r / min for 5min. The resulting supernatant is a dispersion of single-layer graphene with a concentration of 0.20mg / mL and containing about 12wt%. The prepared graphene dispersion has no obvious Tyndall effect, its zeta potential is -22.6mV, and the average particle diameter of graphene is 720.5nm.

Embodiment 3

[0054] A preparation method of a stable graphene colloidal dispersion, comprising the following processing steps:

[0055] Dissolve the graphene in Example 1 in 100 mL of 1-naphthoic acid of 4 mg, 98 wt %, 99.7 wt % ethanol, 70 kHz ultrasonic for 30 min to peel and disperse, centrifuge at 12000 r / min for 5 min, and wash 2 to 3 times with distilled water , Wash away residual 1-naphthoic acid and ethanol. Disperse the precipitate in 100mL distilled water, ultrasonicate at 70kHz for 30min, and centrifuge at 10,000r / min for 5min. The resulting supernatant is a colloidal dispersion with a concentration of 0.25mg / mL and containing about 25wt% single-layer graphene. The prepared stable graphene colloidal dispersion has Tyndall effect, its zeta potential is -36.2mV, and the average particle diameter of graphene is 387.3nm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| volume | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com