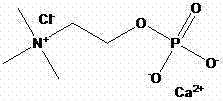

Method for preparing phosphorylcholine chloride calcium salt tetrahydrate

A technology for phosphoryl choline chloride calcium salt and tetrahydrate, which is applied in the field of preparation of phosphoryl choline chloride calcium salt tetrahydrate, can solve the problems of many impurities and a large amount of waste water, and achieves high product purity and no The effect of three wastes generation and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] Example 1: A preparation method of phosphorylcholine chloride calcium salt tetrahydrate

[0028] Add 1032g of orthophosphoric acid into a 2L four-neck flask, heat it to 160~165°C, add dropwise the mixed clarified solution of 1032g of orthophosphoric acid and 852g of choline chloride, and continue to react at 160~165°C for 2 hours until Anhydrous evaporated. A total of about 520 g of water was collected.

[0029] Transfer the feed liquid into a 50-liter glass reactor. After the temperature drops to 30°C, add 15kg of purified water, stir until the solution is colorless, clear and transparent, and the pH is between 1 and 2, add 520g of calcium chloride, and stir at room temperature until completely dissolved; Slowly add 900g of calcium carbonate, a lot of foam is produced, the feed liquid is white and milky, stir at room temperature for 30min, add calcium hydroxide 540g, stir at room temperature for 30min, keep the pH at 8.0, the feed liquid is white and milky, add 2kg of...

Embodiment 2

[0033] Example 2: A preparation method of phosphorylcholine chloride calcium salt tetrahydrate

[0034] Add 1032g of orthophosphoric acid into a 2L four-neck flask, heat it to 160~165°C, add dropwise the mixed clarified solution of 1032g of orthophosphoric acid and 852g of choline chloride, and continue to react at 160~165°C for 2 hours until Anhydrous evaporated. A total of about 520 g of water was collected.

[0035] Transfer the feed liquid into a 50-liter glass reactor. After the temperature drops to 30°C, add 15kg of purified water, stir until the solution is colorless, clear and transparent, and the pH is between 1 and 2, add 520g of calcium chloride, and stir at room temperature until completely dissolved; Slowly add 900g of calcium carbonate, a lot of foam is produced, the feed liquid is white and milky, stir at room temperature for 30min, add calcium hydroxide 540g, stir at room temperature for 30min, keep the pH at 8.0, the feed liquid is white and milky, add 2kg of...

Embodiment 3

[0039] Embodiment three: a kind of preparation method of phosphorylcholine chloride calcium salt tetrahydrate

[0040] Add 1988g of orthophosphoric acid into a 2L four-neck flask, heat it to 160~165°C, add dropwise the mixed clarified solution of 639g of orthophosphoric acid and 852g of choline chloride, and continue to react at 160~165°C for 2 hours until Anhydrous evaporated. About 503g of water were collected in total.

[0041] Transfer the feed liquid into a 50-liter glass reactor, after the temperature drops to 30°C, add 15kg of purified water, stir until the solution is colorless, clear and transparent, and the pH is between 1 and 2, add 298g of calcium chloride, and stir at room temperature until completely dissolved; Slowly add 1278g of calcium carbonate, a large amount of foam is produced, the feed liquid is white and milky, stir at room temperature for 30min, add calcium hydroxide 670g, stir for 30min at room temperature, keep the pH at 8.0, the feed liquid is white...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com