A kind of nucleating agent polypropylene high-performance composite additive and preparation method thereof

A technology for compounding additives and nucleating agents, applied in the field of plastic additives, can solve the problems of insufficient rigidity, increase production costs, reduce labor efficiency, etc., and achieve the effects of reducing interface free energy, improving production efficiency, and shortening molding cycle.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032]

[0033] (1) Put all the components into the cantilever double-helix cone mixer according to the above weight ratio for premixing and coarse dispersion;

[0034] Cantilever double-helix cone mixer, model: DSH-1.5CD, made of stainless steel, the process operation speed is 40-50 rpm, and the mixing time is 40 minutes. The flow rate output is controlled within the range of 0.2-0.3 tons / hour.

[0035] (2) After premixing and coarse dispersion, put the obtained mixture into a horizontal ball mill for grinding and fine dispersion. Horizontal ball mill model: QM-500, made of stainless steel, the process control speed is 75-85 rpm, the temperature is controlled at 70°C, and the time is 60 minutes.

[0036](3) After refining and dispersing, put the obtained mixture into twin-screw granulation to extrude granulation to further strengthen the dispersion. Granulator model: TE-65, the temperature inside the machine is controlled within the range of 75-85°C, the discharge temper...

Embodiment 2

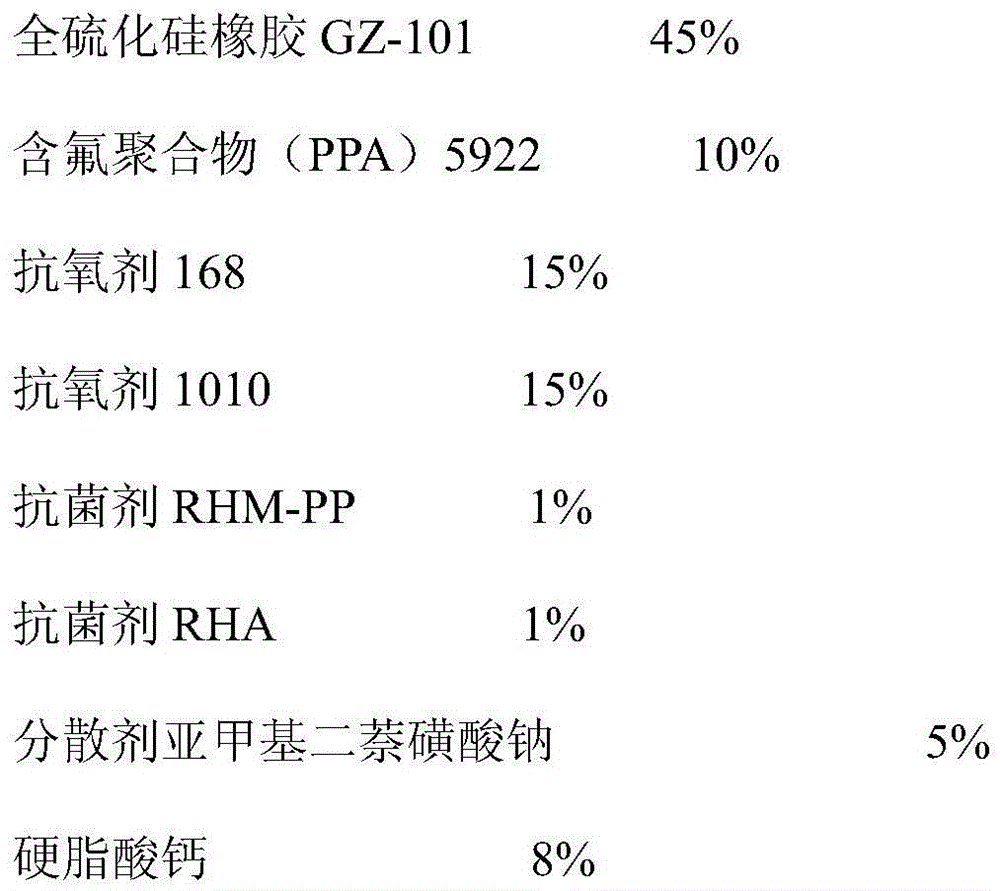

[0043] formula:

[0044]

[0045] The preparation steps of Example 2 are the same as Example 1, except that the stirring time of Step 1 is increased to 60 minutes, and other control indicators are the same as Example 1.

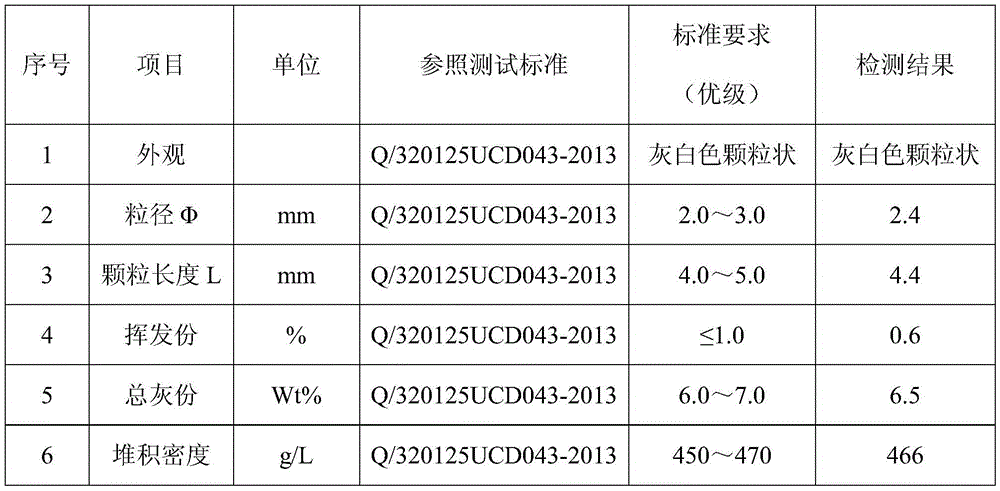

[0046] Table 3 Contrast table between the main index of the auxiliary agent in Example 2 of the present invention and the inspection achievement index

[0047]

[0048]

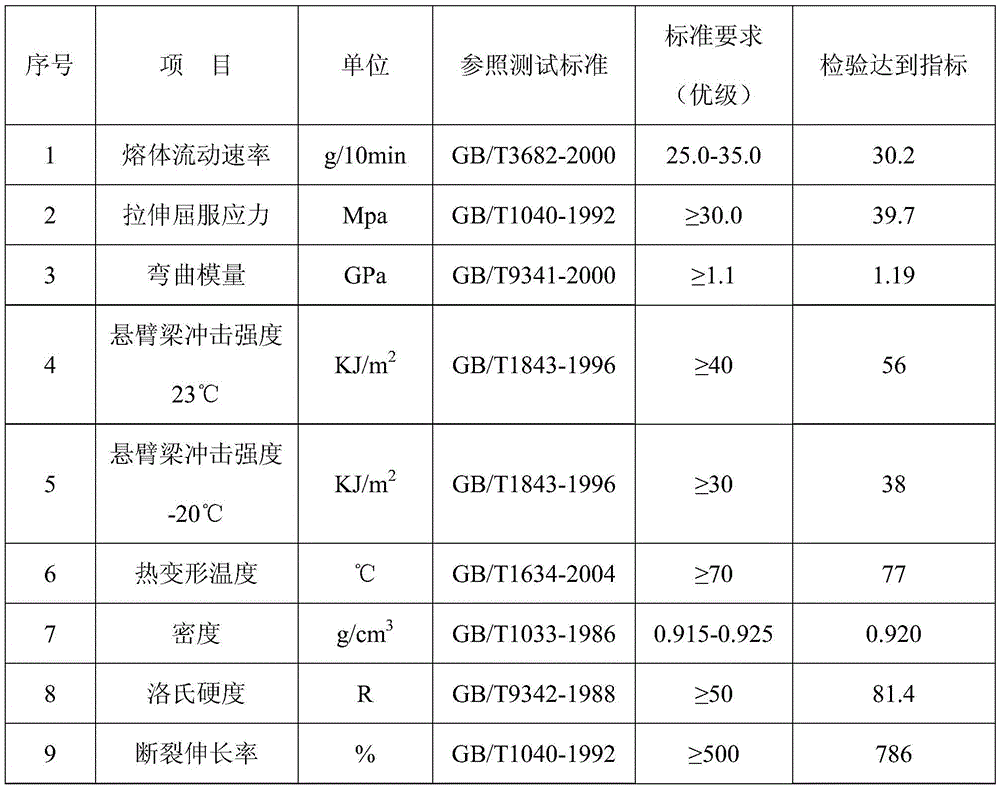

[0049] Table 4 The main inspection indicators achieved by the application of the auxiliary agent in Example 2 of the present invention to M30RH resin

[0050]

Embodiment 3

[0052] formula:

[0053]

[0054] The preparation steps of Example 3 are the same as those of Example 1, except that the stirring time of Step 1 is increased to 80 minutes, and other control indicators are the same as those of Example 1.

[0055] Table 5 Contrast table between the main index of the auxiliary agent in Example 3 of the present invention and the inspection achievement index

[0056]

[0057] Table 6 The main inspection indicators achieved by applying the auxiliary agent of Example 3 of the present invention to M30RH resin

[0058]

[0059] .

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com