A binary fluoropolymer wetting reversal agent and its preparation method and application

A technology of wetting reversal and polymerization, which is applied in drilling compositions, chemical instruments and methods, and earth-moving drilling, etc., can solve the problems of wetting reversal capability and cost that need to be improved, and improve oil and gas recovery. rate, improve wettability, and reduce the effect of interfacial free energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

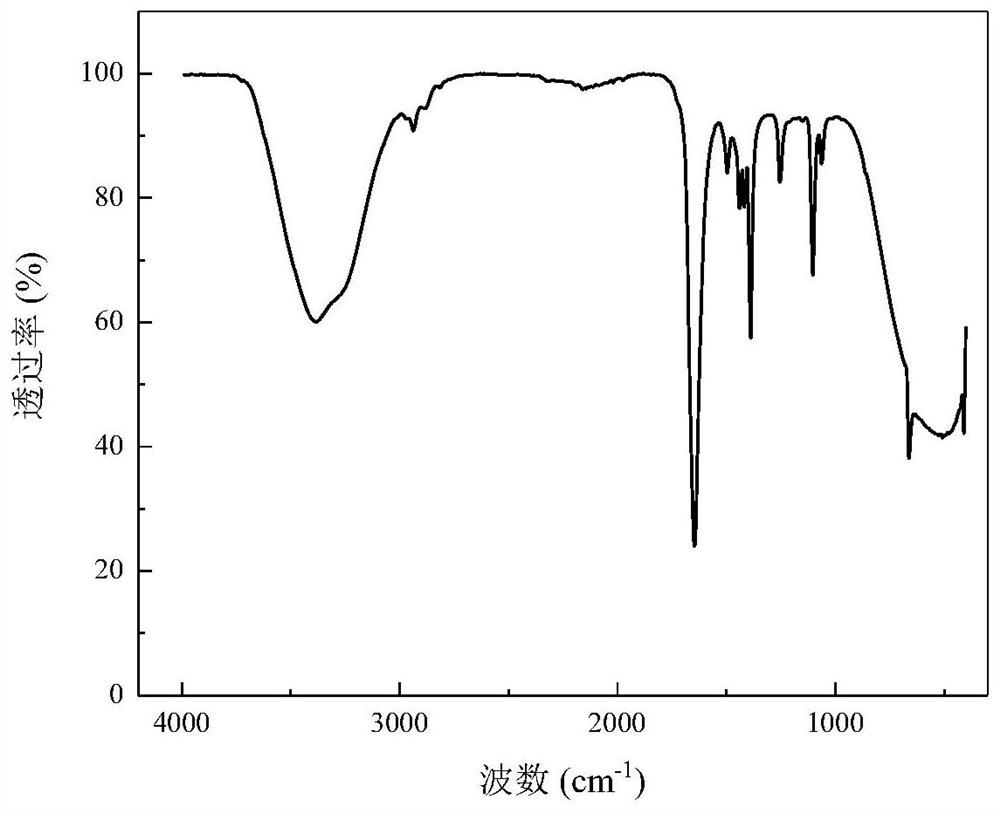

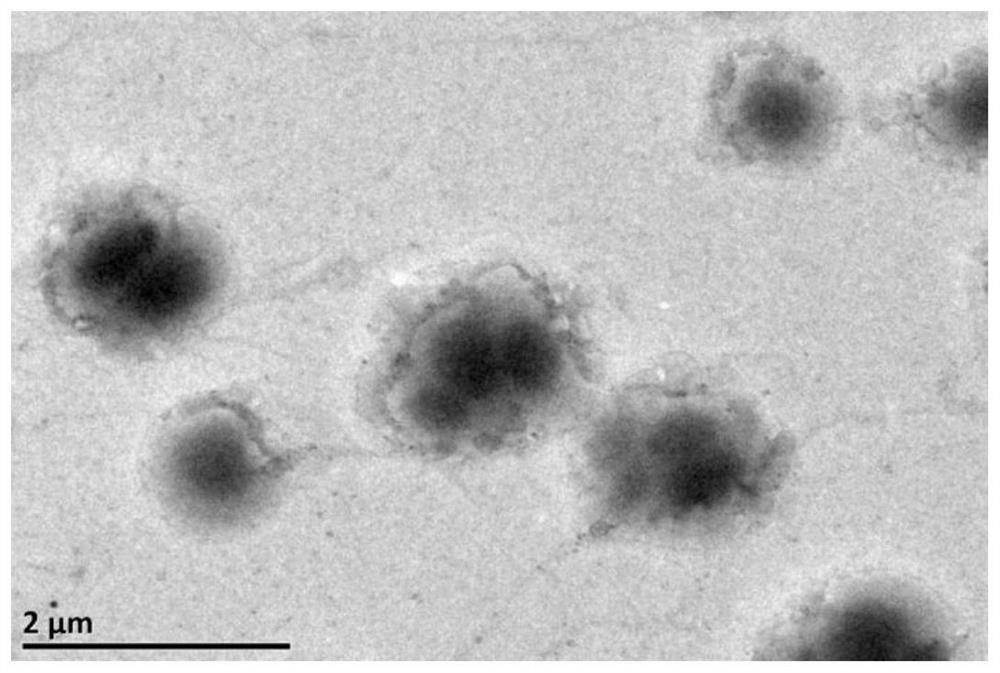

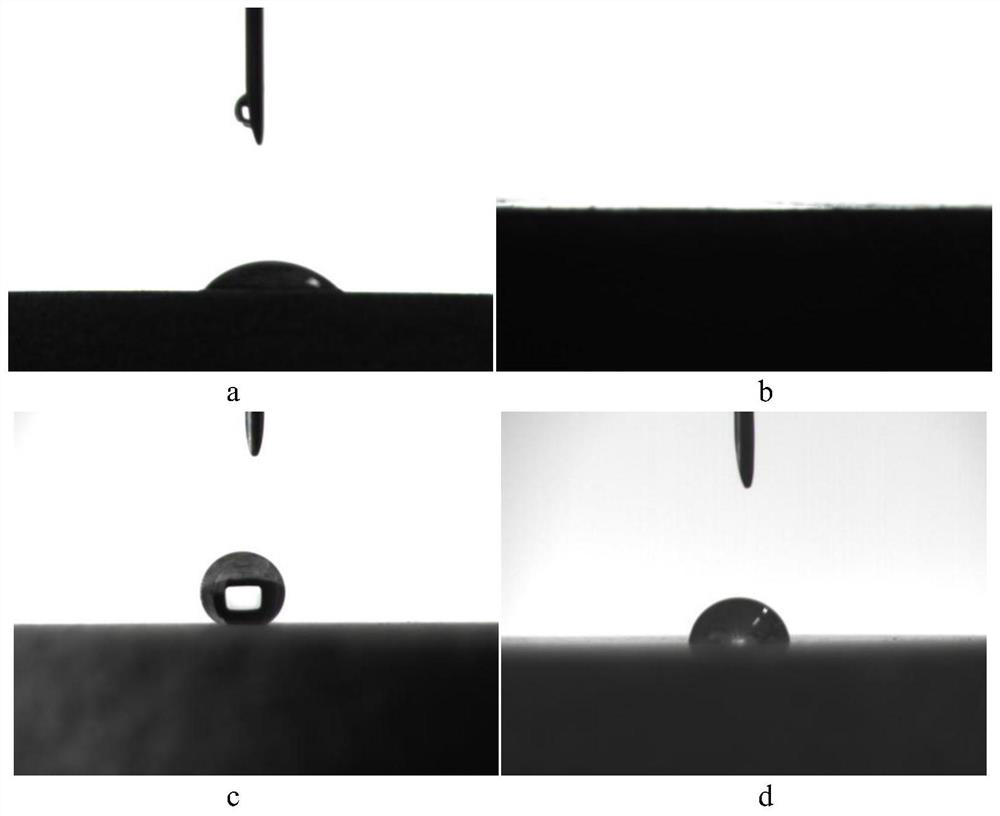

[0047] In a 250mL three-necked flask with a reflux device and electromagnetic stirring, add 50mL of distilled water and 0.4g of perfluorooctanoic acid respectively, and then add 4.0g (0.01mol) of dodecafluoroheptyl methacrylate and 4.3g (0.01mol) of 2- (Perfluorohexyl) ethyl methacrylate, ultrasonic emulsification at room temperature for 30min. Then 2.8g (0.02mol) butyl methacrylate (acrylic monomer) and 0.16g initiator azobisisobutyronitrile (AIBN) were dissolved in 50mL of N,N-dimethylformamide (DMF) , drop it into a three-necked flask at a rate of 2-3d / s at 60°C, and then raise the temperature to 80°C for 4 hours to react for 4 hours to obtain a milky white binary fluoropolymer microemulsion, which is a wetting reversal agent . Transmission electron microscope image of binary fluoropolymer microemulsion figure 2 As shown, the emulsion has a small particle size, the minimum can reach 1 μm, and the stability is strong.

[0048] The obtained product has the structure shown ...

Embodiment 2

[0050] The preparation method was as described in Example 1, except that the acrylic monomer was 5.0 g (0.02 mol) of dodecyl methacrylate. The obtained product has the structure shown in formula I, wherein R is dodecyl, n=20, and the weight average molecular weight is about 27000.

Embodiment 3

[0052] The preparation method was as described in Example 1, except that the acrylic monomer was 5.5 g (0.02 mol) of 9-anthracene methyl methacrylate.

[0053] The obtained product has the structure shown in formula I, wherein R is 9-anthracenemethyl, n=20, and the weight average molecular weight is about 28000.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com