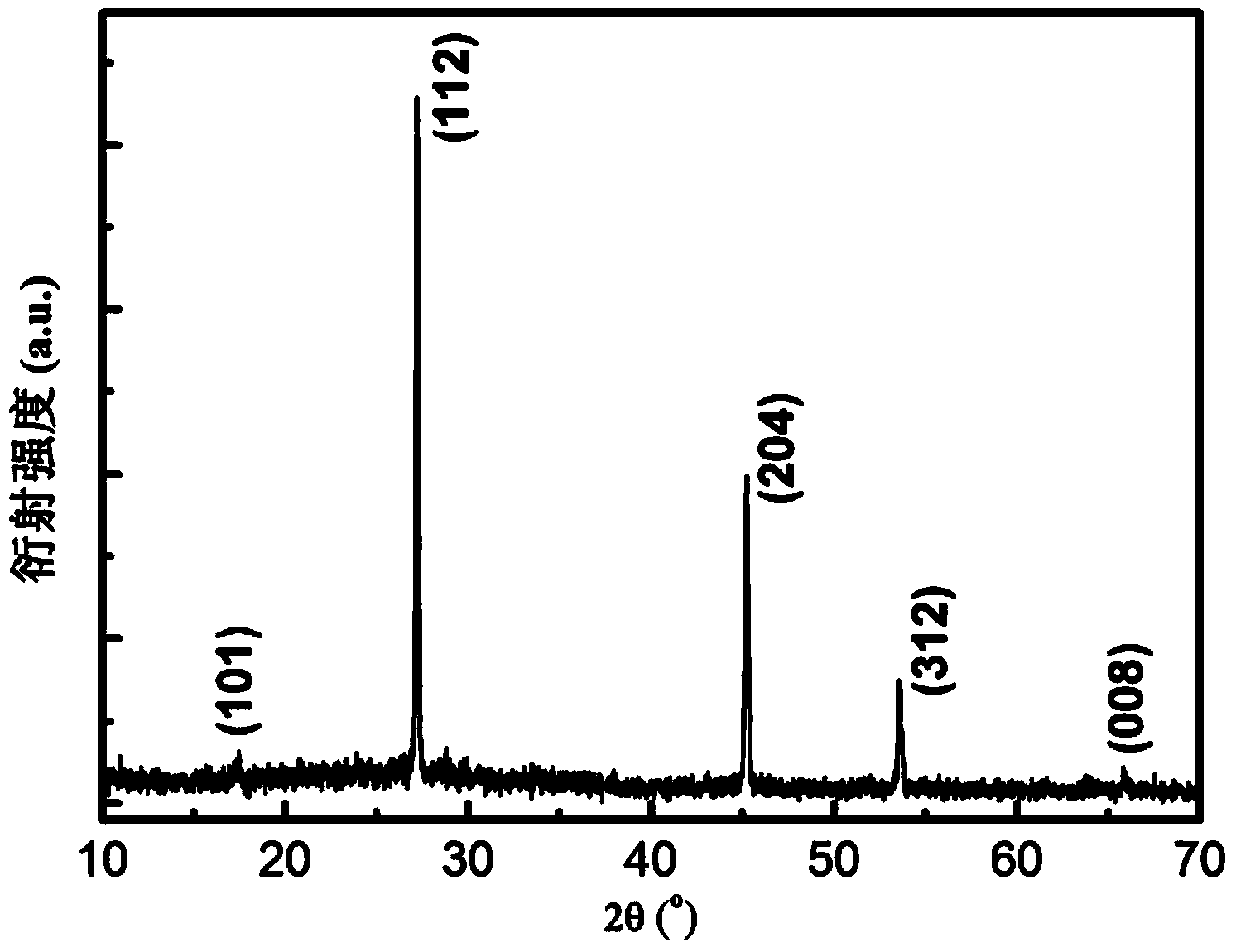

Preparation method of copper-ferrum-tin-selenium thin film

A thin film, tin-selenium technology, applied in the field of solar photovoltaic materials, can solve the problems of difficult control of element ratio, large surface roughness, poor crystallization of thin film, etc., and achieve the effect of simple and convenient method, high quality and easy control of thin film components

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0028] 1. Clean the glass substrate: Use acetone, ethanol and deionized water to perform ultrasonic cleaning in sequence, and store it in deionized water after cleaning.

[0029] 2. Using the magnetron sputtering method, the background vacuum is 5×10 through the molecular pump. -4 Pa, then feed Ar gas, adjust the vacuum to the working pressure, deposit tin metal layer, iron metal layer and copper metal layer sequentially on the glass substrate from bottom to top to obtain a layered metal thin film precursor, in which the sputtering The sputtering process parameters of the tin target are: sputtering power 40W, sputtering pressure 1.2Pa, sputtering time is 6 minutes; the sputtering process parameters of the iron target are: sputtering power: 80W, sputtering pressure 1.6Pa , the sputtering time is 5 minutes; the sputtering process parameters of the copper target are: sputtering power: 80W, sputtering pressure 1.6Pa, and the sputtering time is 3 minutes and 50 seconds.

[0030]3....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com