Non-brazed MOCVD spray nozzle capable of being washed online by chlorine gas

A non-brazing and nozzle technology, applied in gaseous chemical plating, metal material coating process, coating, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

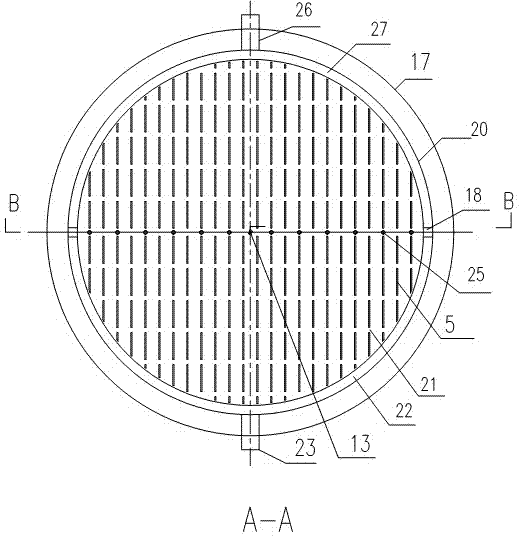

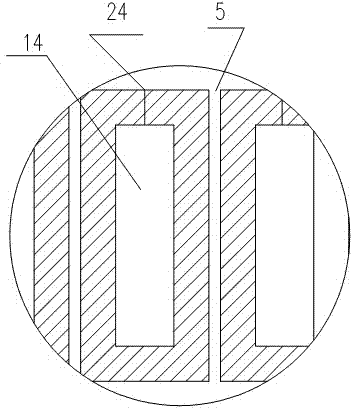

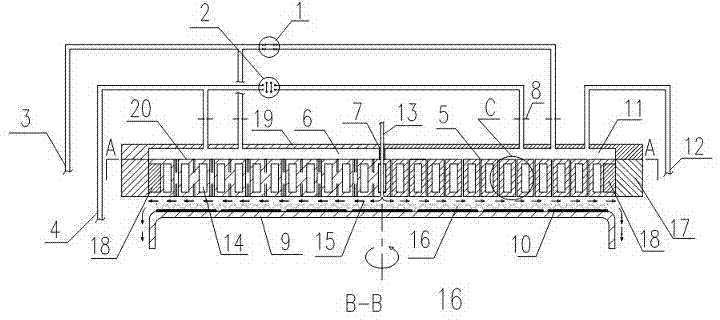

[0019] In order to abandon the stainless steel brazing process that is not resistant to chlorine, the design of the spray nozzle plate 20 conforms to the EDM process: after cutting out a plurality of refrigerant channels 14 by the wire EDM method, each wire cutting wire is blocked by the arc welding method Seam 24, and then vertically cut out a plurality of air jet seams 5 with electric spark; The surface area of the air jet seam 5 processed by EDM is smaller than that of machining under the condition of the same roughness, so the epitaxial memory effect is small. The reason why the air jet slit 5 is disconnected in the length direction is that the first is to distribute the air evenly, and the second is that the nozzle plate of the nozzle should be provided with reinforcing ribs 21; the thickness of the nozzle plate 20 increases, and the depth of the corresponding air jet slit 5 is also deep. Therefore, the resistance to the gas is large, and the gas can be sprayed evenly fr...

Embodiment 2

[0025] Example 3:

[0026] Embodiment 3 is basically the same as Embodiment 1, the difference lies in:

Embodiment 3

[0027] For the processing of the spray head spray plate 20, it is preferable to use electric cremation to drill all the air spray slits 5 at one time.

[0028] This needs to be prepared in advance with copper electrodes complementary in shape to all air jet slots 5 . This processing method is a common practice in the mold industry when EDM cavity molds. With such a copper electrode, all the air-jet slits 5 can be quickly punched out at one time, and the copper electrode can be used repeatedly. (A structural invention is incomplete if the processing method is not mentioned. Therefore, I still write the processing method. With the structure and the processing method of the nozzle, there is the advantage of the present invention-it can be washed with chlorine)

[0029] It should be noted that the above-mentioned embodiments are only descriptions of the present invention rather than limitations of the present invention, and any non-essential replacement or modified inventions tha...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com