Method for preparation of SiBN(C) ceramic fiber precursor by one-pot technique

A ceramic fiber and precursor technology, which is applied in the field of preparation of silicon boron nitrogen ceramic precursors, can solve the problems of high brittleness and low strength of ceramic fiber precursors, and achieve the effects of easy operation, brittleness and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

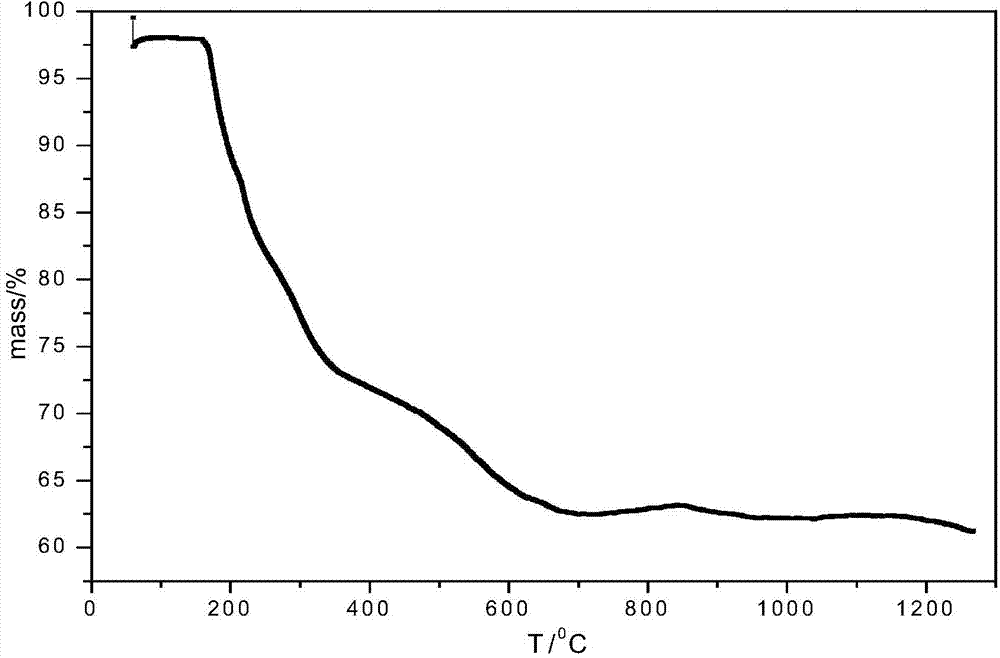

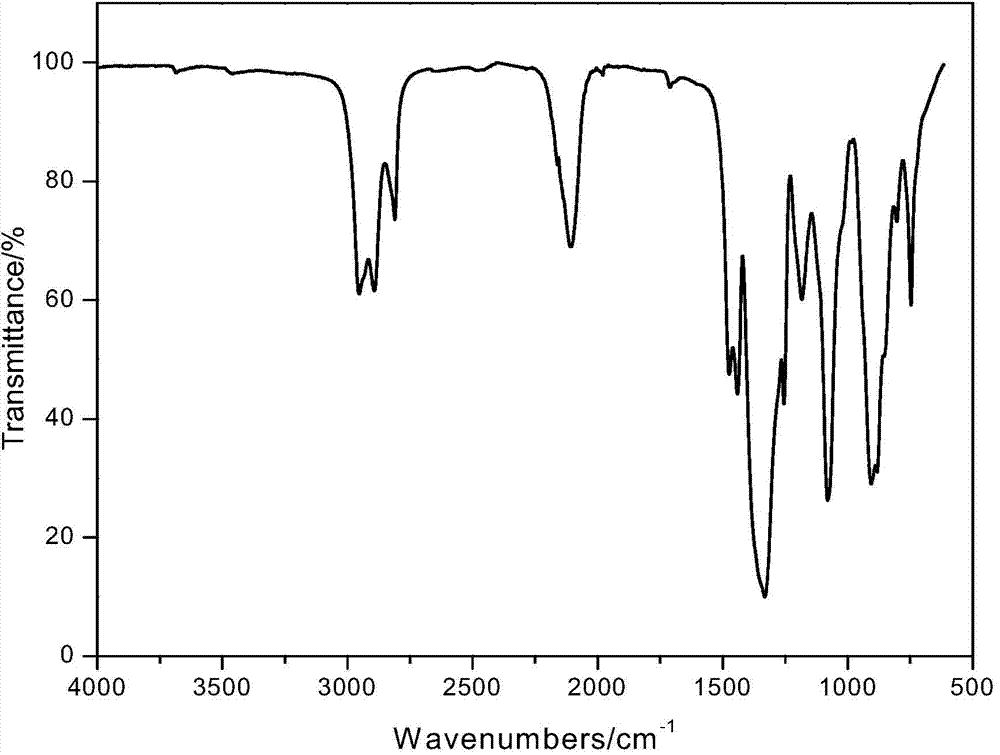

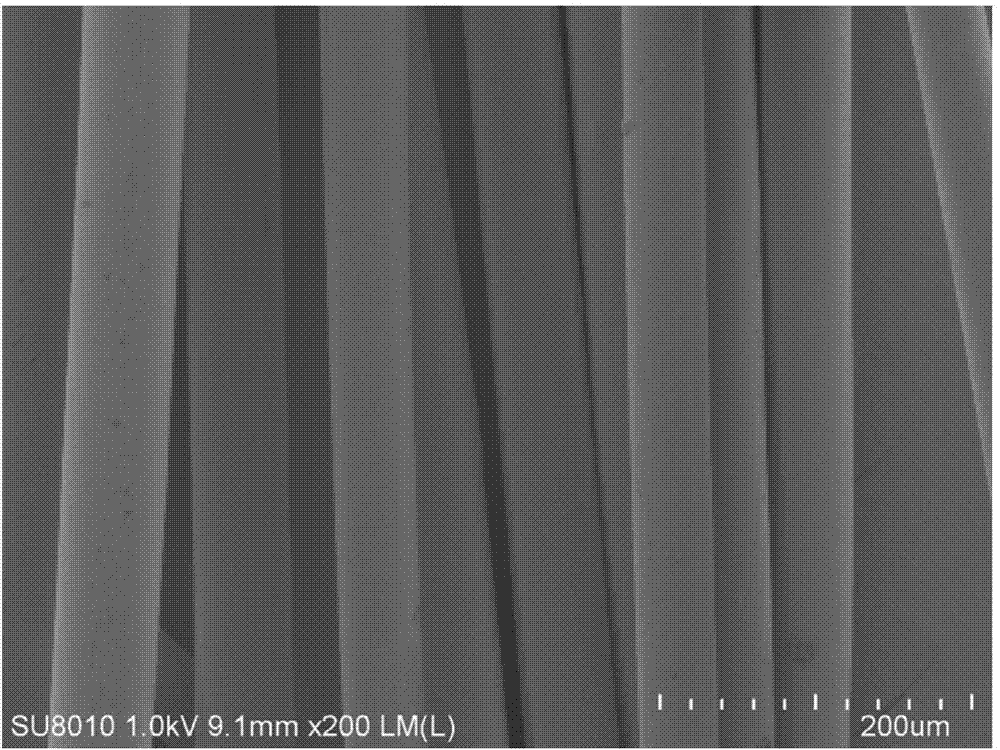

Embodiment 1

[0027] (1) Put 2L of anhydrous n-hexane into the reactor, and distill and clean the reactor at 85°C; (2) At -13°C, put 10L of anhydrous n-hexane into the reactor, and then pass into the liquid Methylamine 1.8L, then take MeHSiCl 2 3.75mol and 1mol / L BCl 3 Mix 2.5L of n-hexane solution evenly, and mix the mixed methyldichlorosilane and BCl 3 The solution is added into the anhydrous n-hexane solution of methylamine through an electromagnetic pump, and an exothermic reaction occurs in the container. The temperature in the reactor is controlled at -15 to -10°C by a circulating cooling pump. After the addition is completed, the reaction is carried out at room temperature for 24 hours. The obtained upper liquid is an anhydrous n-hexane solution of SiBN (C) ceramic fiber precursor molecules; (3) Take the n-hexane solution of SiBN (C) ceramic fiber precursor molecules obtained after the reaction in a three-necked flask, at Under the conditions, the n-hexane in the precursor molecule...

Embodiment 2

[0029] (1) Introduce 2L of anhydrous n-hexane into the reactor at a temperature of 85°C, and distill and clean the reactor; (2) Introduce 9L of anhydrous n-hexane into the reactor at -17°C, and then in liquid state Methylamine 1.5L, then take MeHSiCl 2 2.5mol and 1mol / L BCl 3 Mix 2.5L of n-hexane solution evenly, and mix the mixed methyldichlorosilane and BCl 3 The solution is added into the anhydrous n-hexane solution of methylamine through an electromagnetic pump, and an exothermic reaction occurs in the container. The temperature in the reactor is controlled at -20 to -15°C by a circulating cooling pump. After the addition is completed, the reaction is carried out at room temperature for 24 hours. The obtained upper liquid is an anhydrous n-hexane solution of SiBN (C) ceramic fiber precursor molecules; (3) Take the n-hexane solution of SiBN (C) ceramic fiber precursor molecules obtained after the reaction in a three-necked flask, at Under the conditions, the n-hexane in t...

Embodiment 3

[0031] (1) Introduce 2L of anhydrous n-hexane into the reactor at a temperature of 85°C, and distill and clean the reactor; (2) Introduce 9L of anhydrous n-hexane into the reactor at -17°C, and then in liquid state Methylamine 1.5L, then take MeHSiCl 2 2.5mol and 1mol / L BCl 3 Mix 2.5L of n-hexane solution evenly, and mix the mixed methyldichlorosilane and BCl 3The solution is added into the anhydrous n-hexane solution of methylamine through an electromagnetic pump, and an exothermic reaction occurs in the container. The temperature in the reactor is controlled at -20 to -15°C by a circulating cooling pump. After the addition is completed, the reaction is carried out at room temperature for 24 hours. The obtained upper liquid is an anhydrous n-hexane solution of SiBN (C) ceramic fiber precursor molecules; (3) Take the n-hexane solution of SiBN (C) ceramic fiber precursor molecules obtained after the reaction in a three-necked flask, at Under the conditions, the n-hexane in th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com