Novel intelligent carrier and control method thereof

A technology for intelligent trucks and trucks, applied in two-dimensional position/channel control, manufacturing tools, manipulators, etc., can solve the problems of low guidance accuracy, waste of manpower and material resources, and low level of intelligence, so as to improve work efficiency. Efficiency and intelligence, increased operational flexibility, the effect of high functional integration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

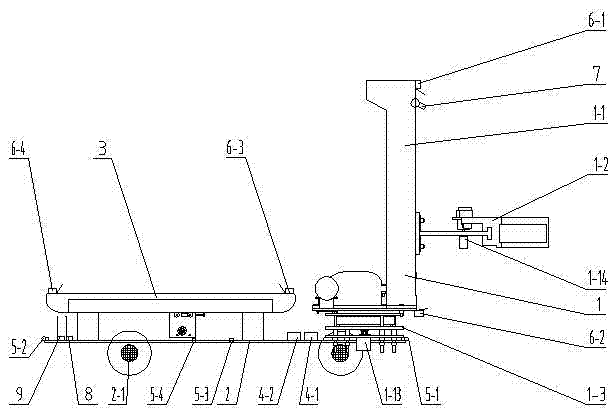

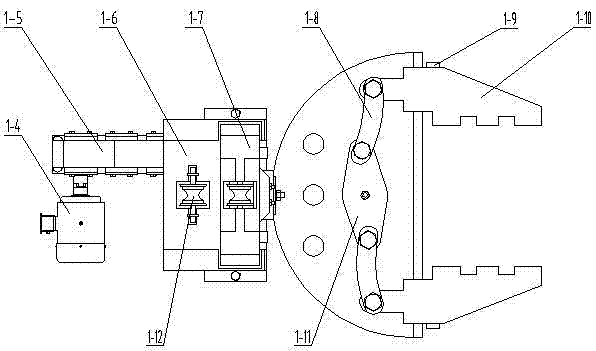

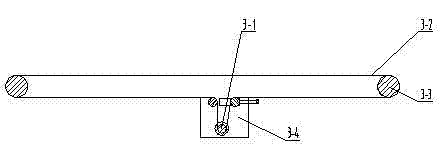

[0049] Such as figure 1As shown, the mechanical gripper module 1 includes a lifting mechanism 1-1, a gripper 1-2 and a rotating base 1-3 for gripping and placing objects; the rotating base 1-3 is driven by the first steering gear 1-13 and Fixed on the vehicle body 2; the driving motor module 4 includes a first driving device 4-1 and a second driving device 4-2, and the first driving device 4-1 controls the first DC motor 2-1 and the second DC motor 3 -1. The third DC motor 1-4 works, and the second driving device 4-2 controls the work of the first steering gear 1-13 and the second steering gear 1-14; the limit module 6 includes a first limit switch 6-1 , the second limit switch 6-2, the third limit switch 6-3, and the fourth limit switch 6-4, which are respectively installed at the upper and lower limit positions of the lifting mechanism 1-1 and the transmission module The front and rear limit positions of 3 are used for the position control of the gripper module 1 and the tr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com