Lithium ion battery anode coating technology

A lithium-ion battery and coating process technology, applied in battery electrodes, electrode manufacturing, electrolyte layer coatings, etc., can solve the problems of lithium-ion battery performance degradation, high production site toxicity, affecting battery performance and other problems, and achieve high production site toxicity. , the effect of high production cost and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0014] Mix styrene-butadiene rubber and sodium carboxymethyl cellulose, the mass fraction of which is 1% of styrene-butadiene rubber and 0.7% of sodium carboxymethyl cellulose, and mix and stir for 30 minutes. Then add the positive electrode material lithium cobaltate, stir for 30 minutes, and finally add acetylene black, the mass fraction of acetylene black: 2%, and stir for 2 hours. After stirring, let it stand for 10 minutes to form a paste. Spread the paste evenly on the aluminum foil with a coating thickness of 120 μm. After coating, put it in an oven at 80° C. to dry it to become a positive electrode sheet.

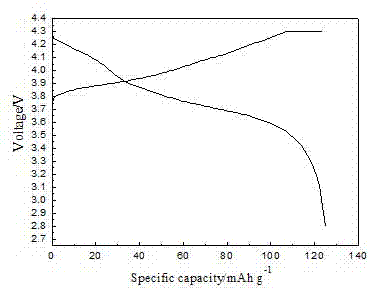

[0015] Assemble the positive electrode sheet into a battery, and test the electrochemical performance of the battery, figure 1 It is the first charge-discharge curve. It can be seen from the figure that the charge and discharge curves of the material each have a platform, and the charge-discharge performance is good.

Embodiment 2

[0017] Mix styrene-butadiene rubber and sodium carboxymethyl cellulose, the mass fraction is 5% of styrene-butadiene rubber and 1.0% of sodium carboxymethyl cellulose, and mix and stir for 40 minutes. Then add the positive electrode material lithium cobaltate, stir for 40 minutes, finally add acetylene black, the mass fraction of acetylene black is 6%, and stir for 2 hours. After stirring, let it stand for 10 minutes to form a paste. Spread the paste evenly on the aluminum foil with a coating thickness of 120 μm. After coating, put it in an oven at 80° C. to dry it to become a positive electrode sheet.

Embodiment 3

[0019] Mix styrene-butadiene rubber and sodium carboxymethyl cellulose, the mass fraction of which is 3% of styrene-butadiene rubber and 0.4% of sodium carboxymethyl cellulose, and mix and stir for 20 minutes. Then add the positive electrode material lithium cobaltate, stir for 20 minutes, finally add acetylene black, the mass fraction of acetylene black is 4%, and stir for 2 hours. After stirring, let it stand for 10 minutes to form a paste. Spread the paste evenly on the aluminum foil with a coating thickness of 80 μm. After coating, place it in an oven at 80°C to dry to become a positive electrode sheet.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com