Preparation method of radix tetrastigme powder

A cloverleaf, powder-forming technology, applied in the directions of medical preparations containing active ingredients, pharmaceutical formulations, and devices for making medicines into special physical or taking forms, etc. The problem of high cost, to achieve the effect of saving resources, stable quality and convenient storage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

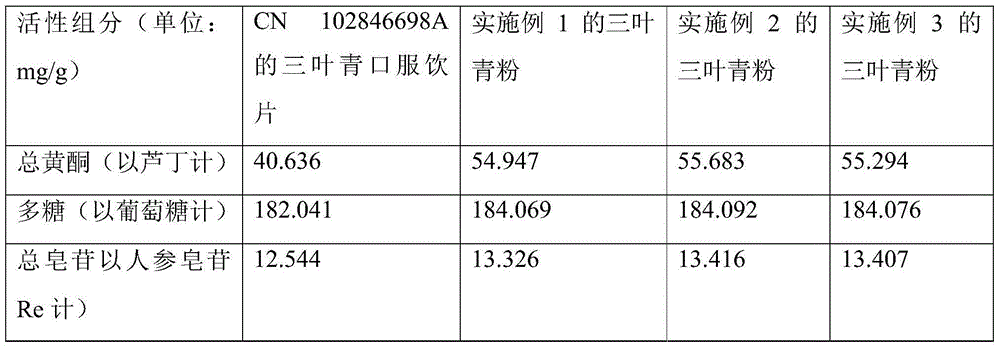

Examples

Embodiment 1

[0029] (1) Pretreatment: Take fresh clover herb, remove impurities, wash with water, cut into 2-4mm thick slices;

[0030] (2) Freezing at low temperature: spread out the three leaf green slices obtained in step (1) and freeze them at -5°C.

[0031] (3) Low-temperature pulverization: pulverize the three leaf green tablets obtained in step (2) at a low temperature of -5°C, and sieve to obtain a coarse powder of 40-100 meshes.

[0032] (4) Low-temperature vacuum microwave drying: Put the clover powder obtained in step (3) into a vacuum microwave drying box for low-temperature vacuum microwave drying, control microwave power: 1kw, vacuum degree: 0.04Pa, temperature: -5°C ;The total time of microwave drying is 2h. During the microwave drying process, the microwave treatment method is adopted at intervals of 30s and heating for 30s (that is, heating for 30s, stopping heating for 30s, then continuing heating for 30s, stopping heating for 30s, and cycling in turn).

[0033] (5) Low-...

Embodiment 2

[0037] (1) Pretreatment: Take fresh clover herb, remove impurities, wash with water, cut into 2-4mm thick slices;

[0038] (2) Freezing at low temperature: spread out the three leaf green slices obtained in step (1) and freeze them at -40°C.

[0039] (3) Low-temperature pulverization: pulverize the three leaf green tablets obtained in step (2) at a low temperature of -50°C, and sieve to obtain a coarse powder of 40-100 meshes.

[0040] (4) Low-temperature vacuum microwave drying: The three-leaf green powder obtained in step (3) is subjected to low-temperature vacuum microwave drying, controlling microwave power: 15kw, total microwave drying time, 0.5h, temperature: -50°C; vacuum degree: 0.09 Pa. During the microwave drying process, the microwave treatment method is adopted with an interval of 30s and heating for 60s (that is, heating for 30s, stopping heating for 60s, then continuing heating for 30s, then stopping heating for 60s, and cycling in turn).

[0041] (5) Low-tempe...

Embodiment 3

[0045] (1) Pretreatment: Take fresh clover herb, remove impurities, wash with water, cut into 2-4mm thick slices;

[0046] (2) Freezing at low temperature: spread out the three leaf green slices obtained in step (1) and freeze them at -20°C.

[0047] (3) Low-temperature pulverization: pulverize the trifoliate green slices obtained in step (2) at a low temperature of -20°C, and sieve to obtain a coarse powder of 40-100 meshes.

[0048] (4) Low-temperature vacuum microwave drying: The trifolium clover coarse powder obtained in step (3) is subjected to low-temperature vacuum microwave drying, microwave power: 6kw, total microwave drying time, 1h, temperature: -35°C; vacuum degree: 0.08Pa. During the microwave drying process, the microwave treatment method is adopted at an interval of 60s and heated for 90s (that is, after heating for 90s, stop heating for 60s, then continue heating for 90s, then stop heating for 60s, and cycle in turn).

[0049] (5) Low-temperature airflow pulve...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com