Welding method of C-SiC sputtering target material

A welding method and sputtering target technology, which can be used in welding equipment, non-electric welding equipment, metal processing equipment, etc., can solve the problems of de-soldering between the target material and the backplane, difficult wetting treatment, etc., to achieve pure solder and increase the wetting effect. , The effect of saving product processing time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

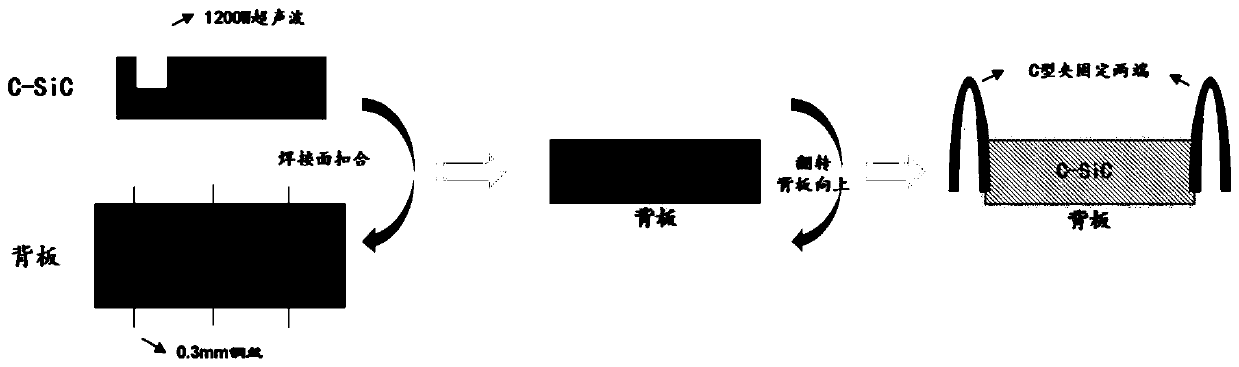

[0042] This embodiment provides a welding method for C-SiC sputtering targets such as figure 1 As shown, the method includes the following steps:

[0043] (1) Perform shielding treatment on the C-SiC target and the back plate, then place solder on the welding surface of the C-SiC target and the back plate after shielding and heat up, after the temperature rise is completed, perform the welding process on the welding surface of the C-SiC and the back plate Wetting treatment to obtain the treated C-SiC target and back plate; the masking treatment is to use heat-resistant tape to cover the non-welding surface; the amount of solder added is 0.5kg; the solder is indium solder; The end temperature of the heating is 210°C; the infiltration treatment is carried out by an ultrasonic brazing machine; the power of the ultrasonic brazing machine is 1200W; the time of the infiltration treatment is 25min; the oxidized solder on the surface of the solder is removed after the infiltration tre...

Embodiment 2

[0049] This embodiment provides a welding method for a C-SiC sputtering target, the method comprising the following steps:

[0050] (1) Perform shielding treatment on the C-SiC target and the back plate, then place solder on the welding surface of the C-SiC target and the back plate after shielding and heat up, after the temperature rise is completed, perform the welding process on the welding surface of the C-SiC and the back plate Wetting treatment to obtain the treated C-SiC target and back plate; the masking treatment is to use heat-resistant tape to cover the non-welding surface; the amount of solder added is 0.8kg; the solder is indium solder; The end temperature of the heating is 230°C; the infiltration treatment is carried out by an ultrasonic brazing machine; the power of the ultrasonic brazing machine is 1300W; the time of the infiltration treatment is 20min; the oxidized solder on the surface of the solder is removed after the infiltration treatment ;

[0051] (2) ...

Embodiment 3

[0056] This embodiment provides a welding method for a C-SiC sputtering target, the method comprising the following steps:

[0057] (1) Perform shielding treatment on the C-SiC target and the back plate, then place solder on the welding surface of the C-SiC target and the back plate after shielding and heat up, after the temperature rise is completed, perform the welding process on the welding surface of the C-SiC and the back plate Wetting treatment to obtain the treated C-SiC target and back plate; the masking treatment is to use heat-resistant tape to cover the non-welding surface; the amount of solder added is 0.6kg; the solder is indium solder; The end temperature of the heating is 220°C; the infiltration treatment is carried out by an ultrasonic brazing machine; the power of the ultrasonic brazing machine is 1100W; the time of the infiltration treatment is 30min; the oxidized solder on the surface of the solder is removed after the infiltration treatment ;

[0058] (2) ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com