A method for preparing chromatographically purified alpha-linolenic acid ethyl ester

A technology for ethyl linolenate and chromatographic purification, which is applied in the field of preparation of chromatographic purification of α-ethyl linolenate, can solve the problems of high energy consumption, complex process, low purification efficiency of α-ethyl linolenate, etc., and achieve low energy consumption , simple process and stable stationary phase

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

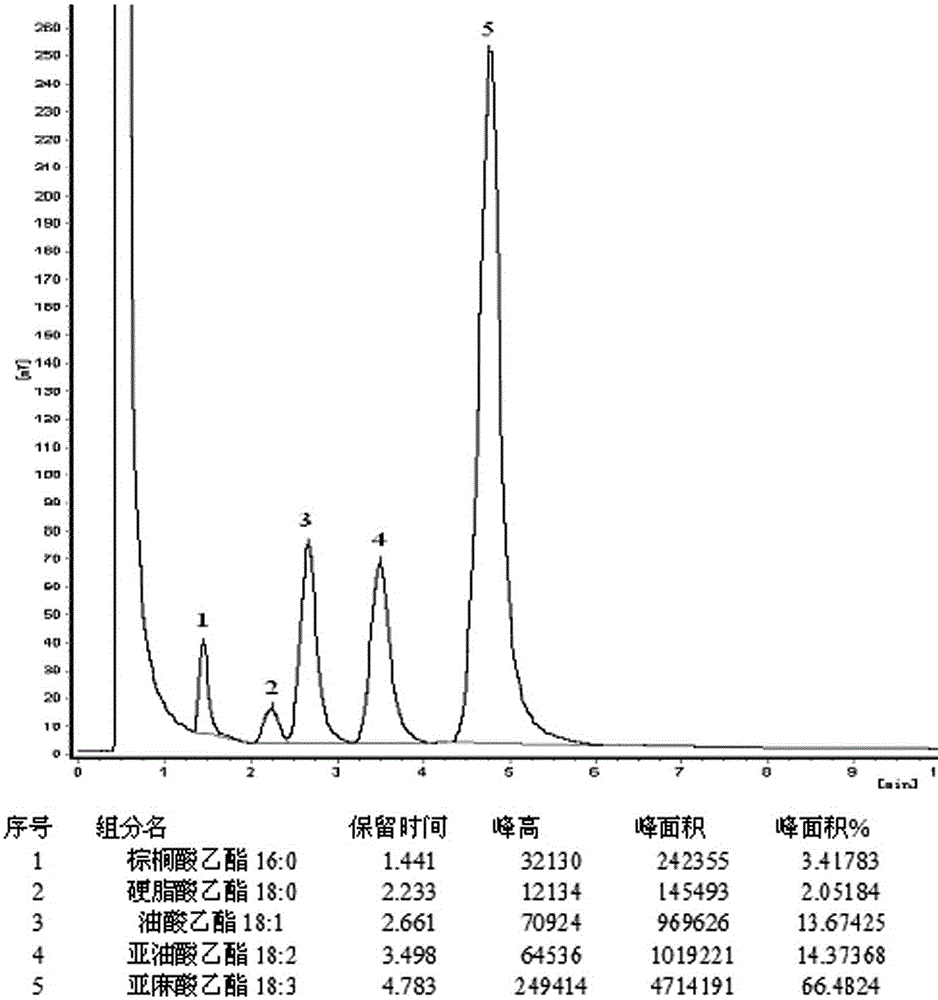

Embodiment 1

[0019] 1. Column packing: put the stationary phase ODS with a particle size of 30-50 μm in ethanol, stir and remove air bubbles, and then evenly load the stationary phase ODS into the prepared chromatographic column. The diameter of the chromatographic column is 15mm and the length is 460mm. Rinse with eluent for 24 hours, open the preparative chromatographic column for secondary filling, rinse again for 24 hours, open the preparative chromatographic column for third filling, and obtain the packed preparative chromatographic column after the stationary phase ODS is compacted;

[0020] 2. Feed: Feed through the six-port sampling valve, the feed concentration is 100% α-ethyl linolenate, and the feed volume is 4mL;

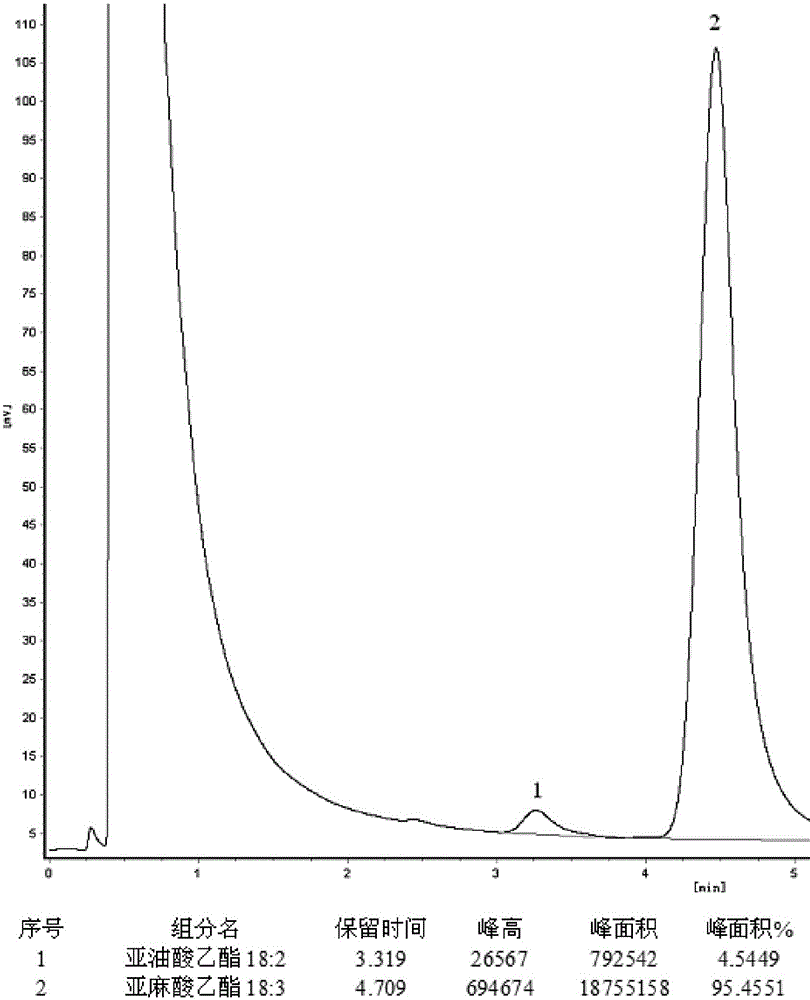

[0021] 3. Elution: pump the eluent with constant pressure and constant flow, the eluent is methanol aqueous solution with a volume fraction of 98%, the amount of eluent is 300mL, and the elution flow rate is 2mL / min; the pressure of the preparation column is 0.4MPa; ...

Embodiment 2

[0025] 1. Column packing: operate according to step 1 in Example 1;

[0026] 2. Feed: Feed through the six-port sampling valve, the feed concentration is 100% α-ethyl linolenate, and the feed volume is 4mL;

[0027] 3. Elution: pump the eluent with constant pressure and constant flow, the eluent is 100% methanol, the amount of eluent is 240mL, and the elution flow rate is 4mL / min; the pressure of the preparation column is 0.3MPa; the column temperature is 30°C;

[0028] 4. Collection: The eluted fraction is collected in sections, and the collection is divided into two times. The first collection is mainly α-linolenic acid ethyl ester component, and 128mL is collected; the second collection is mainly other components, and 112mL is collected. ;

[0029] 5. Recovery of eluent: The eluent was recovered by concentration under reduced pressure, and the purity of ethyl α-linolenic acid was 91.3%, and the yield was 73.2%.

Embodiment 3

[0031] 1. Column packing: operate according to step 1 in Example 1;

[0032] 2. Feed: Feed through the six-port sampling valve, the feed concentration is 100% α-ethyl linolenate, and the feed volume is 4mL;

[0033] 3. Elution: pump the eluent with constant pressure and constant flow, the eluent is 100% methanol, the amount of eluent is 260mL, and the elution flow rate is 4mL / min; the pressure of the preparation column is 0.3MPa; the column temperature is 30°C;

[0034] 4. Collection: The eluted fraction is collected in sections, and the collection is divided into two times. The first collection is mainly α-linolenic acid ethyl ester component, and 152 mL is collected; the second collection is mainly other components, and 108 mL is collected. ;

[0035] 5. Recovery of eluent: Concentrate under reduced pressure to recover the eluent, and the purity of ethyl α-linolenic acid is 85.5%, and the yield is 84.8%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com