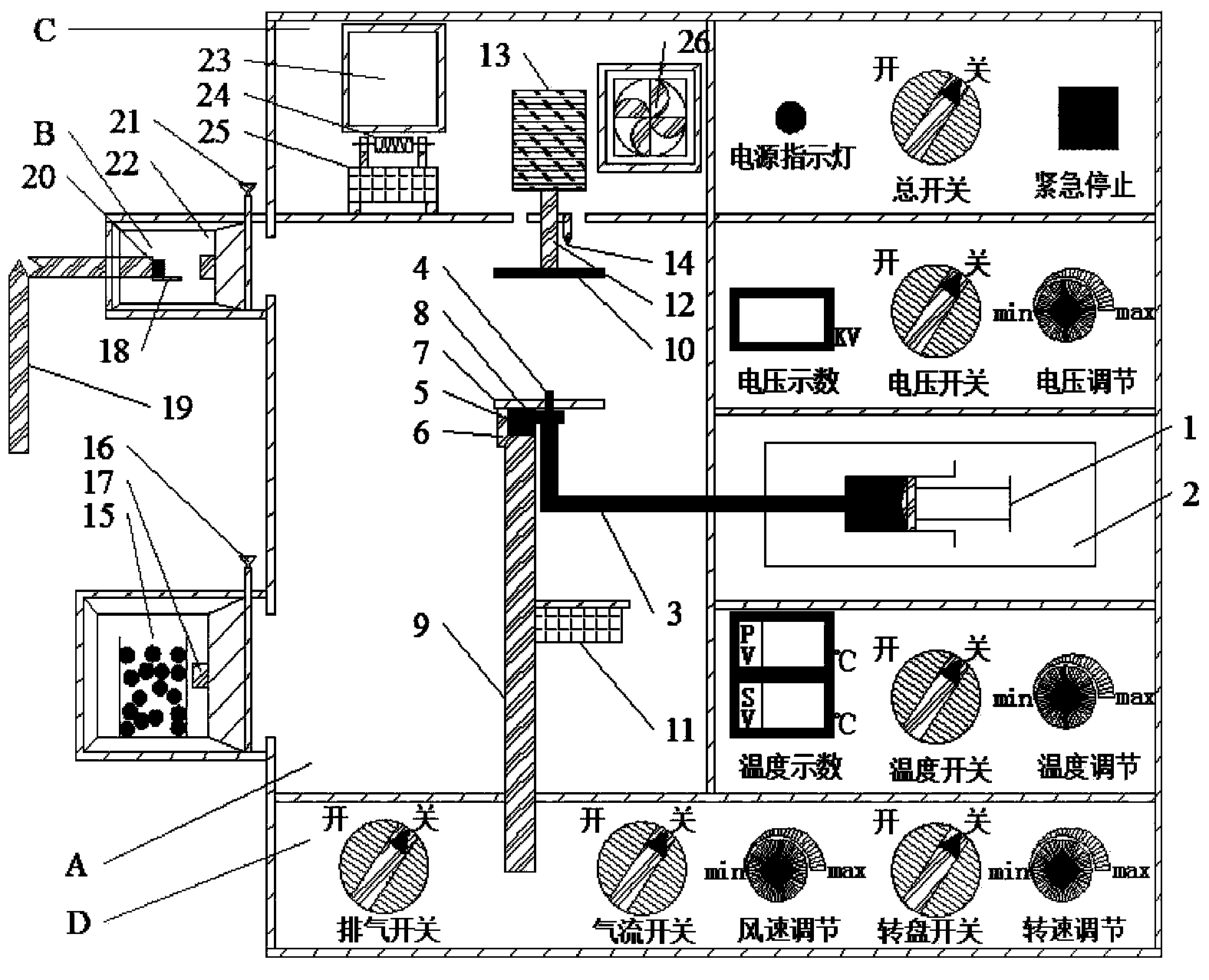

Airflow-assisted electrostatic spinning instrument with real-time sampling function

A real-time sampling, electrospinning technology, applied in the field of electrospinning, can solve the problems of reduced efficiency, long cycle, energy and material consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0068] 1. Accurately weigh 1.000 g polyacrylonitrile (PAN, Sigma-Aldrich, M w =150,000) by adding 17 mL of N,N-dimethylformamide (DMF) solution, and stirring with constant temperature and magnetic force for 3 h in a water bath at 35 °C until completely dissolved to obtain the electrospinning stock solution;

[0069] 2. Take 8 mL of the above-mentioned electrospinning stock solution with a disposable medical injection needle, and carry out electrospinning according to the general operation steps of the instrument. The receiving distance (that is, the distance from the needle to the receiving tray) is 15 cm, and the auxiliary fan is not turned on;

[0070] 3. After 15 minutes of electrospinning (electrospinning reaches a stable state), start sampling. The sampler is a glass slide (specification: 25.4 mm×76.2 mm, thickness 1 mm to 1.2 mm), and the sampling time for 45 s;

[0071] 4. Observe the collected samples directly under a high-power optical microscope and take pictures (...

Embodiment 2

[0077] 1. Accurately weigh 1.000 g of PAN and add 17 mL of DMF solution, stir magnetically at a constant temperature in a water bath at 35 °C for 3 h until completely dissolved, and obtain the electrospinning stock solution;

[0078] 2. Take 8 mL of the above-mentioned electrospinning stock solution with a disposable medical injection needle, and carry out electrospinning according to the general operation procedures of the instrument. The conditions of electrospinning are voltage 15.0 kv, feeding speed 0.5 mL / h, temperature 45°C, Receiving distance (15 cm, the auxiliary fan is not turned on;

[0079] 3. After 15 minutes of electrospinning, start sampling, the sampler is a glass slide, and the sampling time is 45 s;

[0080] 4. Observe the collected samples directly under a high-power optical microscope and take pictures (magnification is 600 times, and the lens has 9 million pixels). The observed partial image is as follows Image 6 shown.

[0081] from Image 6 It can be kn...

Embodiment 3

[0083] 1. Accurately weigh 1.792 g of polyvinylpyrrolidone (PVP), add 10 mL of absolute ethanol and 20 mL of distilled water, stir magnetically at room temperature for 2 h until completely dissolved, and obtain the electrospinning stock solution;

[0084] 2. Take 8 mL of the above-mentioned electrospinning stock solution with a disposable medical injection needle, and carry out electrospinning according to the general operation steps of the instrument. The receiving distance is 15 cm, and the auxiliary fan is not turned on;

[0085] 3. After 15 minutes of electrospinning, start sampling, the sampler is a glass slide, and the sampling time is 25 s;

[0086] 4. Observe the collected samples directly under a high-power optical microscope and take pictures (magnification is 600 times, and the lens has 9 million pixels). The observed partial image is as follows Figure 7 shown;

[0087] 5. Another sample was collected and observed with a scanning electron microscope after process...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com