Method for manufacturing surface plasmon polariton nanometer photonic device

A surface plasmon and nanophotonic technology, applied in the direction of optical waveguide and light guide, can solve the problems of complex preparation, high cost, large size of nanophotonic devices, etc., and achieve simple device preparation process, good grain characteristics and controllability, and process flow. simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

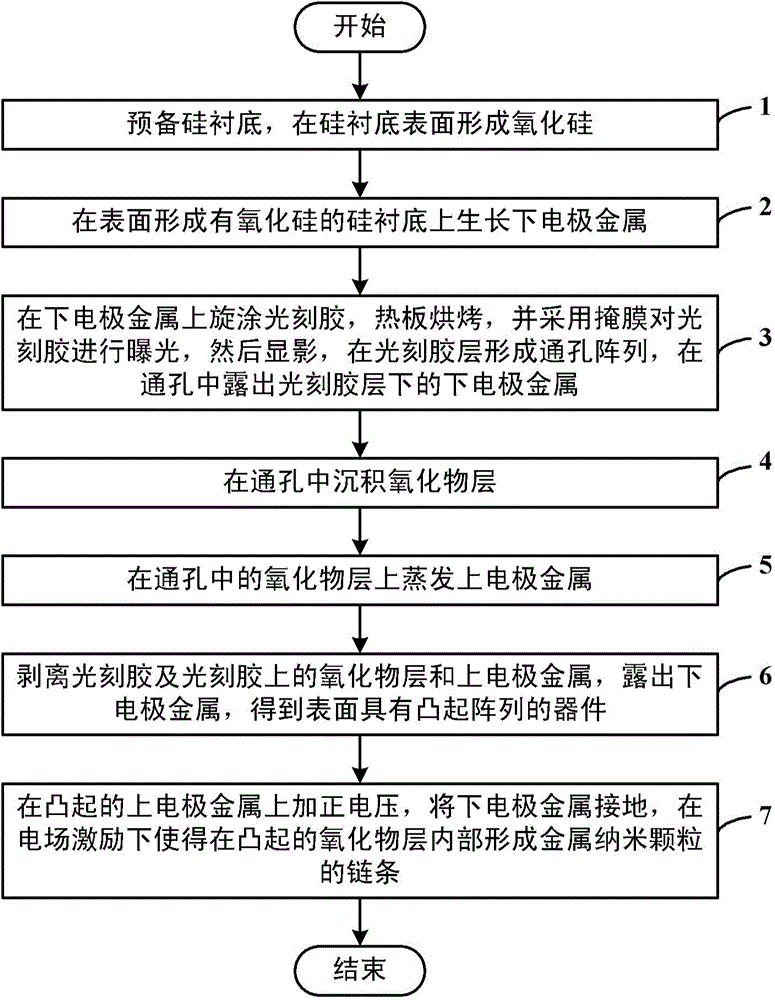

[0051] In this embodiment, a 2-inch silicon substrate is selected, the substrate dielectric layer is made of silicon oxide, the active electrode is made of silver (Ag), and the inert electrode is made of platinum (Pt). In this embodiment, a standard cleaning process is first performed on a 2-inch silicon substrate to remove surface oil and metal contamination. The cleaned silicon substrate is oxidized in a high-temperature oxidation furnace to form insulating silicon oxide on the surface, which is used as a substrate dielectric layer with a thickness of about 100 nanometers. On the silicon substrate formed with silicon oxide, electron beam evaporation forms the lower electrode metal platinum (Pt) with a thickness of 70 nanometers, and then spin-coats 9920 photoresist at a speed of 7000 revolutions per minute, spin coating for one minute, and the thickness is about 1.2 microns. Bake on a hot plate at 85°C for 4.5 minutes. Exposure adopts vacuum exposure mode, and the exposure t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com