Method and apparatus for separating hydrogen sulfide, and hydrogen production system using same

A separation device and manufacturing system technology, applied in the field of hydrogen manufacturing systems, can solve difficult problems such as renewable energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

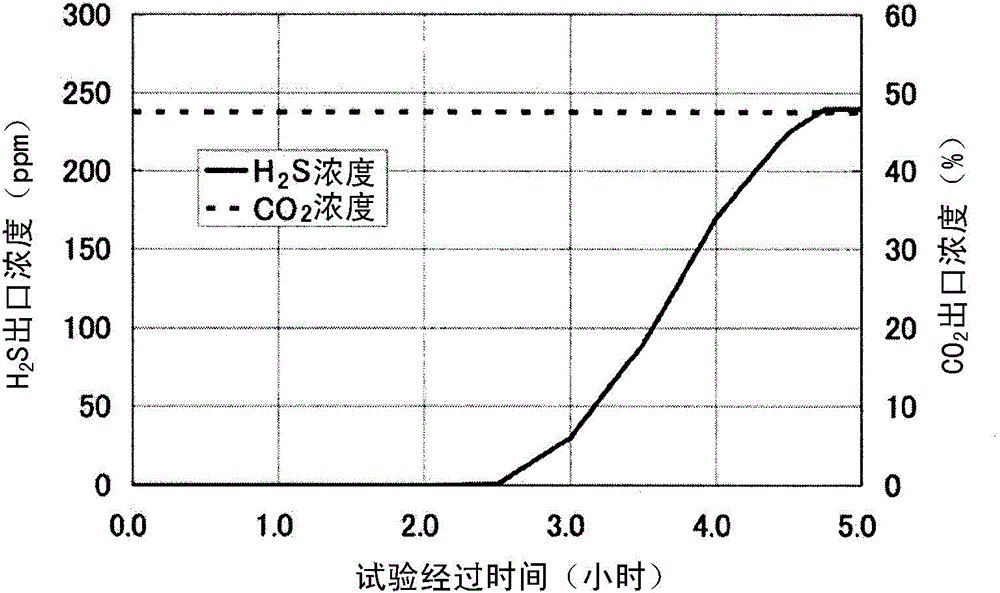

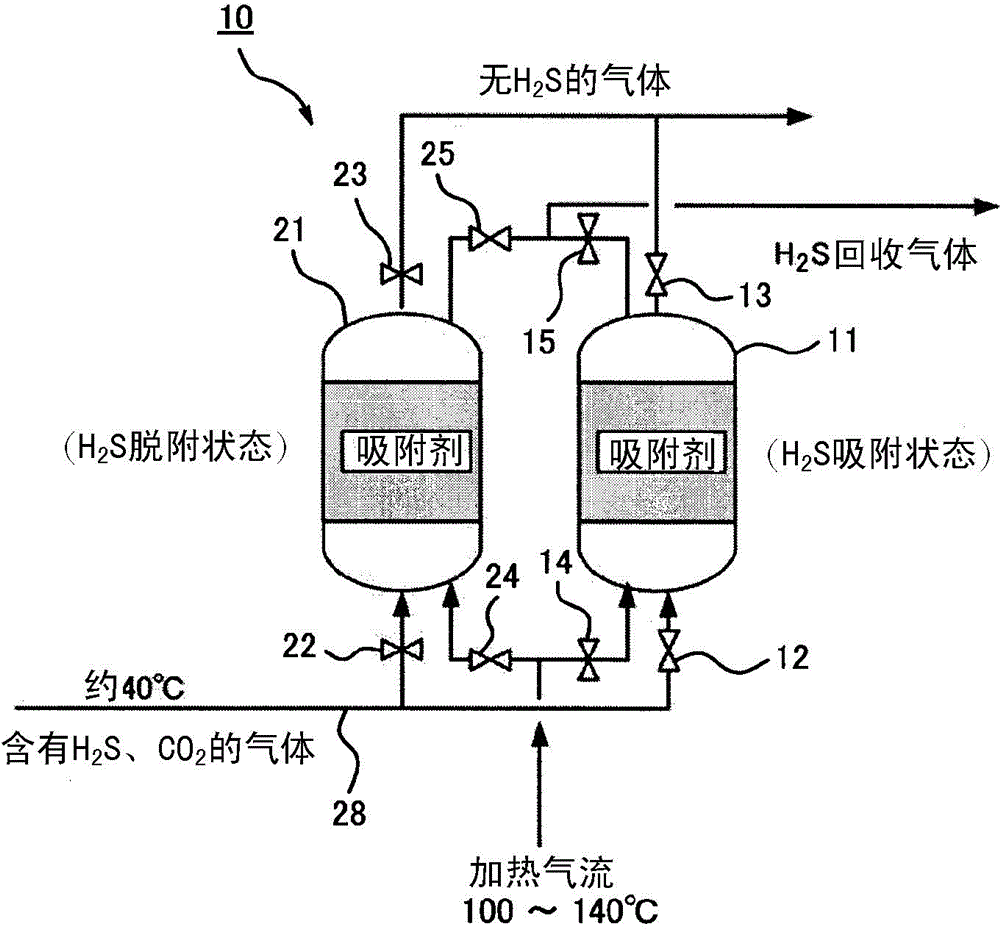

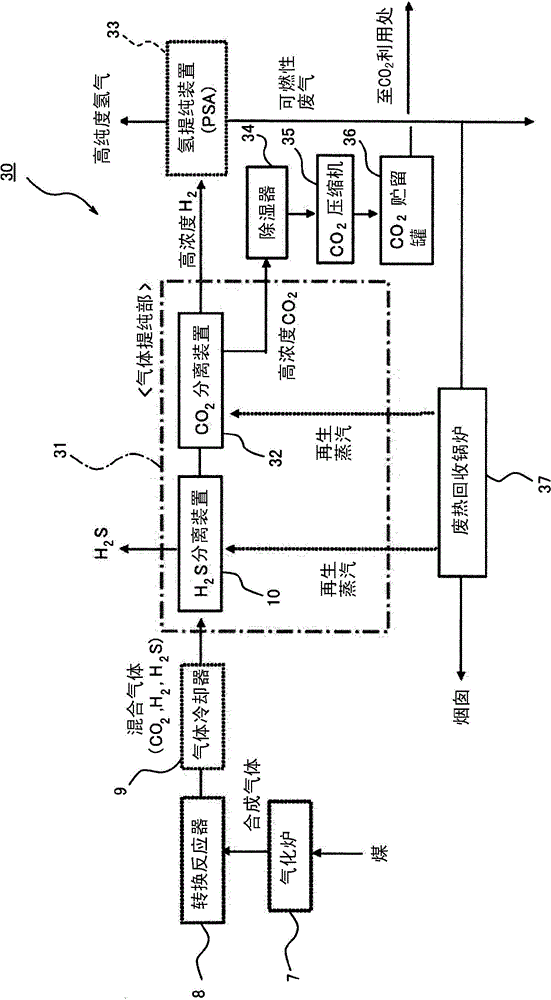

[0048] Embodiments of the present invention will be described below with reference to the drawings, but the present invention is not limited to the following description.

[0049] The hydrogen sulfide adsorbent used in the present invention can be prepared by supporting a tertiary amine on a porous substance to allow the contact between the hydrogen sulfide adsorbent and the gas to be treated to be carried out in a dry state. Activated carbon and activated alumina can be mentioned as porous substances that can be used in the production of hydrogen sulfide adsorbents. In this embodiment, activated carbon can be preferably used as the porous substance. As tertiary amines, tertiary alkanolamines can be preferably used, for example, triethanolamine, N-methyl-diethanolamine, N,N-dimethyl-monoethanolamine, triisopropanolamine, N-methyl-diethanolamine, Diisopropanolamine and N,N-dimethyl-monoisopropanolamine, among which triethanolamine is preferably used. In this embodiment, triet...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com