Positive electrode active material for non-aqueous electrolyte secondary battery, positive electrode for non-aqueous electrolyte secondary battery, and non-aqueous electrolyte secondary battery

一种正极活性物质、非水电解质的技术,应用在非水电解质二次电池领域,能够解决速率特性差、放电容量和放电电压降低等问题,达到成本方面优良的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

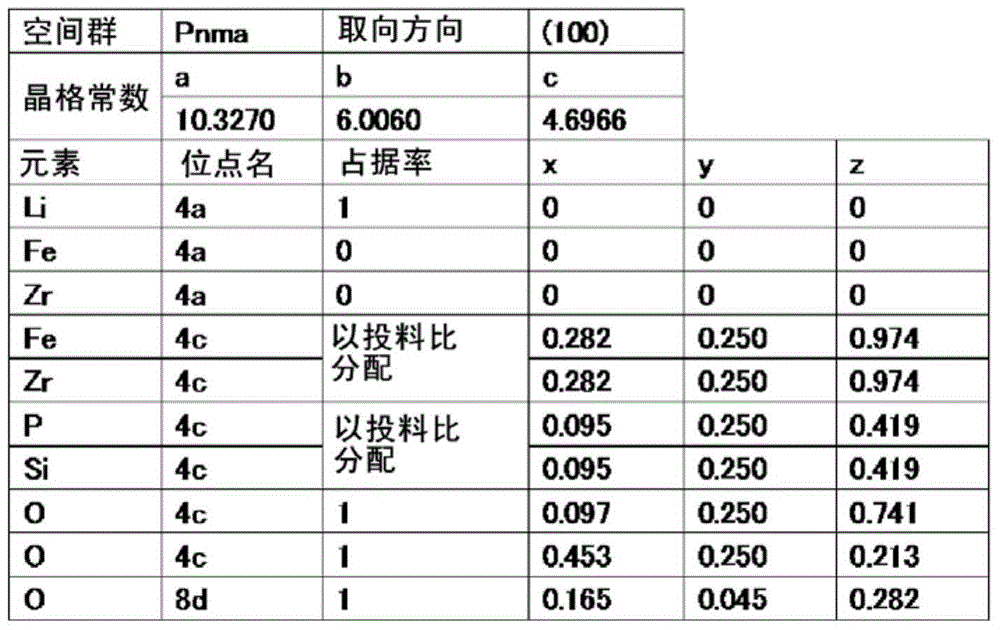

[0084] (Manufacture of positive electrode active material)

[0085] Starting material, using LiCH 3 COO as lithium source, using FeC 2 o 4 2H 2 O as iron source, using ZrO(CH 3 COO) 2 As source of zirconium, Al(NO 3 ) 3 9H 2 O as Al source, using Sn(CH 3 COO) 2 As tin source, use (NH 4 ) 2 HPO 4 As a phosphorus source, use SiO 2 as a silicon source. to make LiCH as a lithium source 3 COO was 0.6599 g, and each of the above-mentioned substances was weighed so that the molar ratio of Li:Fe:Zr:P:Si was 1:0.96:0.04:1.02:0.04. Mix them well with an agate mortar. This mixture was pulverized and mixed using a planetary ball mill. The conditions of the ball mill were a rotation speed of 400 rpm and a rotation time of 1 hour. Balls made of zirconia with a diameter of 10 mm were used, and a jar made of zirconia was also used for the ball mill.

[0086] 15% by weight of sucrose relative to the obtained powder was dissolved in an aqueous solution, and the obtained powder...

Embodiment 2

[0104] (Manufacture of positive electrode active material)

[0105] Starting material, using LiCH 3 COO as lithium source, using FeC 2 o 4 2H 2 O as iron source, using ZrO(CH 3 COO) 2 As zirconium source, use (NH 4 ) 2 HPO 4 As a phosphorus source, use SiO 2 as a silicon source. to make LiCH as a lithium source 3 COO was 0.5345 g, and each of the above-mentioned substances was weighed so that the molar ratio of Li:Fe:Zr:P:Si was 0.81:0.96:0.04:0.83:0.08. Mix them well with an agate mortar. Put the obtained powder into SiO 2 Make a crucible, calcine at a calcination temperature of 550°C, a calcination time of 12 hours, a heating and cooling rate of 200°C / hour, and a nitrogen atmosphere to synthesize the intermediate Li 0.81 Fe 0.96 Zr 0.04 P 0.83 Si 0.08 o 4 single phase powder.

[0106] Next, a lithium source and a phosphorus source that are insufficient in stoichiometry are additionally mixed. The additional material is the same as the starting material, a...

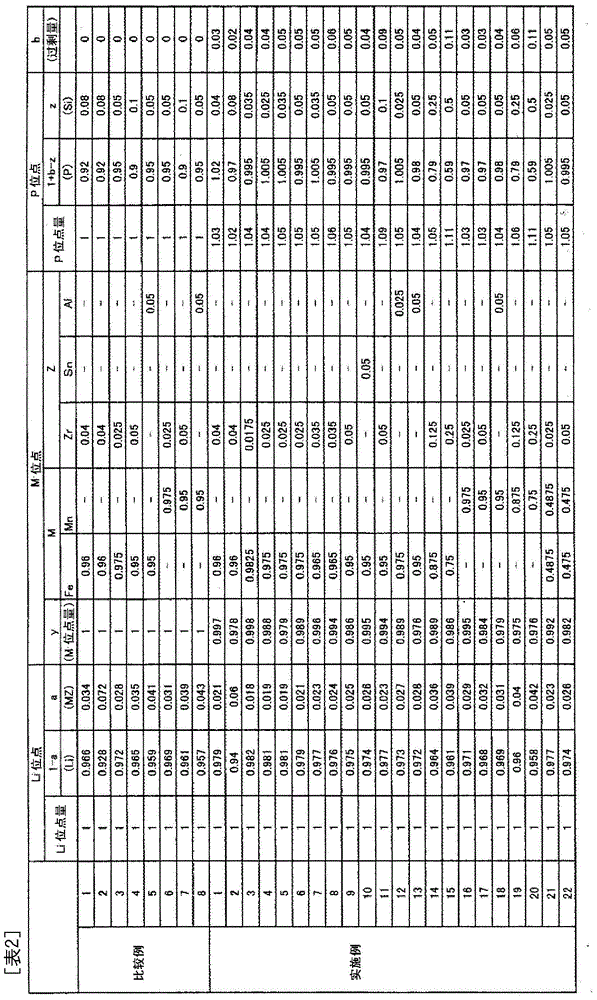

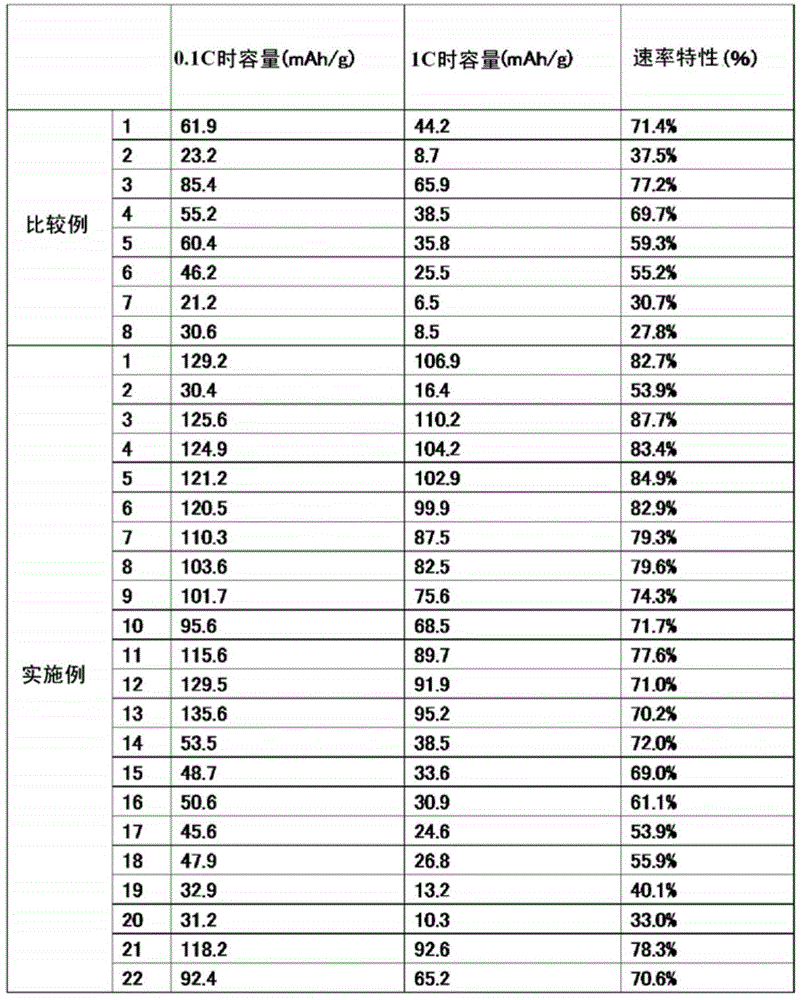

Embodiment 3~22

[0114] (Manufacture of positive electrode active material)

[0115] In addition to making LiCH as a lithium source 3 COO was 0.6599 g and Li:Fe:Zr:P:Si was weighed so that the molar ratios described in Table 2 were the above-mentioned substances, and the powder of the composition ratio described in Table 2 was synthesized by the same procedure as Example 1.

[0116] Using the obtained powder, a positive electrode was produced in the same manner as in Example 1, and charge and discharge measurements were performed.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com