Three-element mixed protective gas for aluminum alloy MIG (Metal-Inert Gas Welding) welding and welding method

A technology of shielding gas and welding method, used in welding/welding/cutting items, welding equipment, welding medium, etc., can solve the problems of fracture resistance, poor fatigue performance, unstable and stable welding process, and large arc range of welded structures. , to achieve the effect of arc not flowing and easy to control, stable ternary mixed gas shielded welding process, and improving welding quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

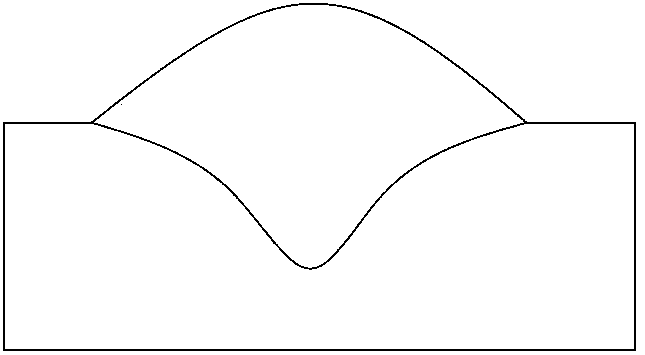

Image

Examples

Embodiment 1

[0061] The composition of helium, argon and nitrogen in the ternary mixed shielding gas for aluminum alloy MIG welding is distributed by volume percentage, which are helium: 20%, argon: 79.995%, nitrogen: 0.005%.

[0062] The above-mentioned ternary mixed shielding gas is used, the meltable welding wire is used as the electrode, and the arc burning between the continuously fed welding wire and the workpiece to be welded is used as the heat source to melt the welding wire and the base metal. The continuous melting of the welding wire should transition in the form of droplets Into the welding pool, it fuses with the molten base metal and condenses to form the weld metal. The ternary mixed shielding gas is continuously delivered to the welding area through the nozzle of the welding torch, so that the arc, the molten pool and the surrounding base metal are protected from the surrounding air. harmful effects.

[0063] The welding arc shrinks obviously, the width of the arc shrinks,...

Embodiment 2

[0065] The composition of helium, argon and nitrogen in the ternary mixed shielding gas for aluminum alloy MIG welding is distributed by volume percentage, which are helium: 40%, argon: 59.974%, nitrogen: 0.026%.

[0066] The above-mentioned ternary mixed shielding gas is used, the meltable welding wire is used as the electrode, and the arc burning between the continuously fed welding wire and the workpiece to be welded is used as the heat source to melt the welding wire and the base metal. The continuous melting of the welding wire should transition in the form of droplets Into the welding pool, it fuses with the molten base metal and condenses to form the weld metal. The ternary mixed shielding gas is continuously delivered to the welding area through the nozzle of the welding torch, so that the arc, the molten pool and the surrounding base metal are protected from the surrounding air. harmful effects.

[0067] The welding arc shrinks obviously, the width of the arc shrinks,...

Embodiment 3

[0069] The composition of helium, argon and nitrogen in the ternary mixed protective gas for aluminum alloy MIG welding is distributed by volume percentage, which are helium: 25%, argon: 74.995%, nitrogen: 0.05%.

[0070] The above-mentioned ternary mixed shielding gas is used, the meltable welding wire is used as the electrode, and the arc burning between the continuously fed welding wire and the workpiece to be welded is used as the heat source to melt the welding wire and the base metal. The continuous melting of the welding wire should transition in the form of droplets Into the welding pool, it fuses with the molten base metal and condenses to form the weld metal. The ternary mixed shielding gas is continuously delivered to the welding area through the nozzle of the welding torch, so that the arc, the molten pool and the surrounding base metal are protected from the surrounding air. harmful effects.

[0071] The welding arc shrinks obviously, the width of the arc shrinks,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com