Deaminizing treatment method of medium-concentration and low-concentration ammonia-nitrogen wastewater under high COD (Chemical Oxygen Demand), salt content and heavy metal content

A low-concentration ammonia nitrogen and treatment method technology, which is applied in the field of wastewater treatment, can solve problems such as complex wastewater components, substandard ammonia nitrogen treatment, and difficult ammonia nitrogen removal, and achieve good water effluent effect, low pollution coefficient, and low operating costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

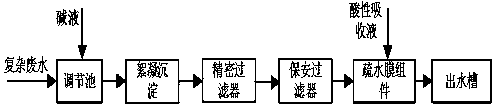

Image

Examples

Embodiment 1

[0040] At room temperature, in the analysis of the substance content of complex wastewater, the concentration of ammonia nitrogen is 50mg / L, the main component of COD is sulfonated kerosene with a content of 2000mg / L, the content of salt is 50g / L, and the heavy metal ion is mainly Cu 2+ , Fe 2+ etc., the content is about 100mg / L, and the calcium concentration is 10mg / L.

[0041] The wastewater enters the adjustment tank for pH adjustment. Sodium hydroxide solution is used to adjust the pH value, and the lye is transported to the adjustment tank by the metering pump to adjust the pH value of the wastewater to about 10.

[0042] After adjusting the pH value, the wastewater enters the flocculation and sedimentation part. With the adjustment of the pH value, fine heavy metals and suspended matter are produced in the wastewater. The suspended solids and heavy metals in the wastewater are flocculated and precipitated by adding flocculant. Polyaluminum chloride is selected as the...

Embodiment 2

[0050] At room temperature, in the analysis of the substance content of complex wastewater, the concentration of ammonia nitrogen is 2000mg / L, the main component of COD is kerosene, the content is 3000mg / L, the salt content is 150g / L, and the heavy metal ion is mainly C U 2+ , Fe 2+ etc., the content is about 150mg / L, and the calcium concentration is 200mg / L.

[0051] The method of each step mentioned in the summary of the present invention is adopted again, that is, the wastewater first enters the adjustment tank for pH adjustment. Sodium hydroxide solution is used to adjust the pH value, and the lye is transported to the adjustment tank by the metering pump until the pH value is adjusted to about 10.

[0052] After adjusting the pH value, the wastewater enters the flocculation and sedimentation part. With the adjustment of the pH value, fine heavy metals and suspended solids are diluted in the wastewater. The suspended solids and heavy metals in the wastewater are floccu...

Embodiment 3

[0060] At room temperature, in the analysis of the substance content of complex wastewater, the concentration of ammonia nitrogen is 3500mg / L, the main component of COD is kerosene, the content is 4000mg / L, the salt content is 200g / L, and the heavy metal ion is mainly C U 2+ , Fe 2+ etc., the content is about 200mg / L, and the calcium concentration is 350mg / L.

[0061] The method of each step mentioned in the summary of the present invention is adopted again, that is, the wastewater first enters the adjustment tank for pH adjustment. Sodium hydroxide solution is used to adjust the pH value, and the lye is transported to the adjustment tank by the metering pump until the pH value is adjusted to about 10.

[0062] After adjusting the pH value, the wastewater enters the flocculation and sedimentation part. With the adjustment of the pH value, fine heavy metals and suspended solids are diluted in the wastewater. The suspended solids and heavy metals in the wastewater are floccu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com