Preparation method of surface porous calcium phosphate ceramic material

A bioceramic material, surface porous technology, applied in medical science, prosthesis, etc., can solve the problems of poor controllability of pores, low load-bearing capacity, low purity of porous calcium phosphate bioceramics, etc., to promote the formation of new bone and maintain support. effect of action

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] A preparation method of a superficially porous calcium phosphate bioceramic material is realized by the following steps:

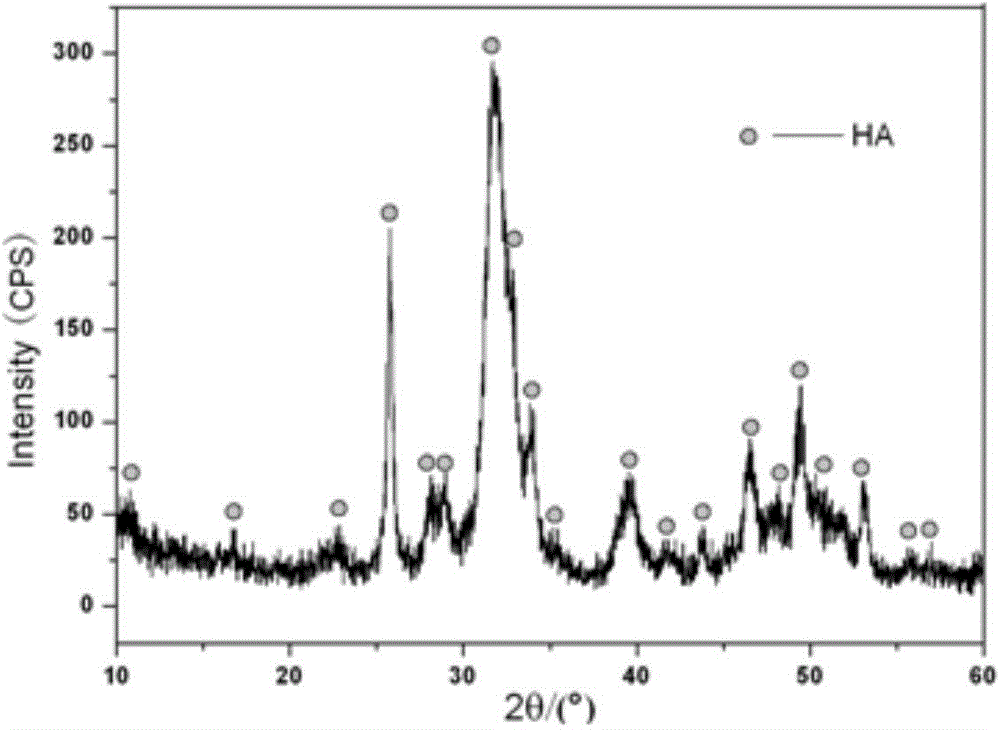

[0026] (1) HA powder is prepared by chemical precipitation method, namely ω ACP =0wt%;

[0027] (2) loading the granulated HA powder into the molding die, and compacting under the condition that the pressure is 300MPa and the holding time is 3min;

[0028] (3) heating the compacted green body to 1150°C, holding it for 2 hours, and naturally cooling it in a sintering furnace to obtain dense HA bioceramics;

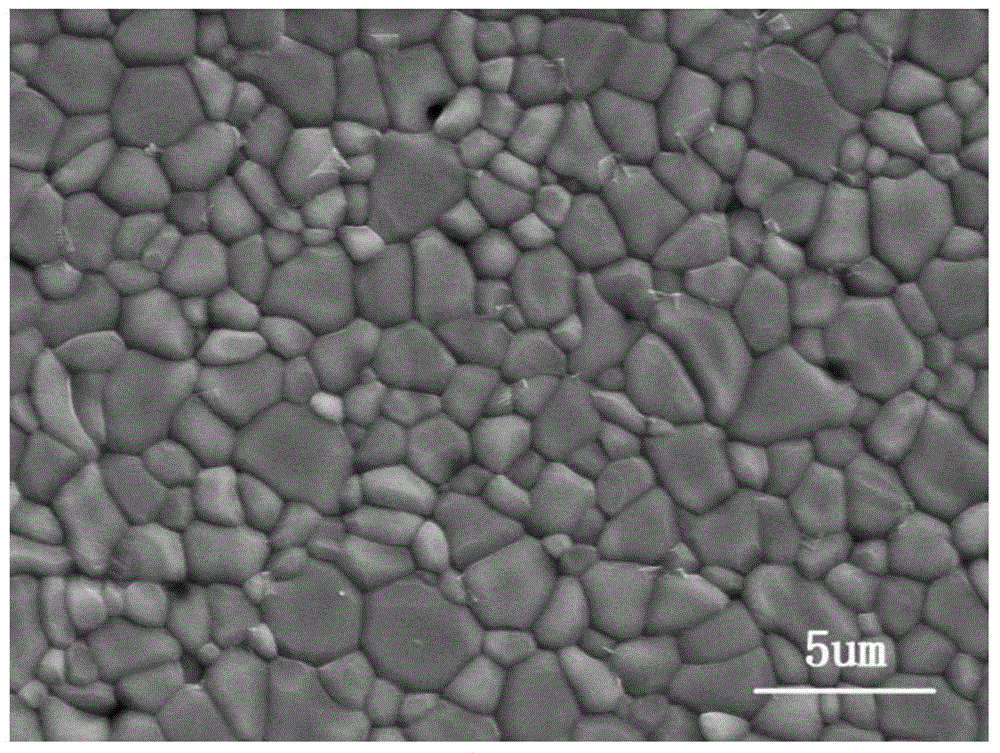

[0029] (4) The dense HA bioceramic was soaked in Tris-HCl buffer at a solid-to-liquid ratio of 10:1 for 28 days to obtain a superficially porous HA bioceramic with a pore size of 1-6 μm. The longer the soaking time, the larger the pore size, and vice versa. The same is true.

Embodiment 2

[0031] A preparation method of a superficially porous calcium phosphate bioceramic material is realized by the following steps:

[0032] (1) ACP and HA were prepared by chemical precipitation method, and mixed according to ACP:HA ratio of 1:3 to obtain ω ACP = 25 wt% ACP / HA mixed powder;

[0033] (2) packing the ACP / HA composite powder after granulation into the molding die, and compacting under the condition that the pressure is 300MPa and the holding time is 3min;

[0034] (3) heating the compacted green body to 1150°C, holding it for 2 hours, and naturally cooling it in a sintering furnace to obtain a dense β-TCP / HA bioceramic, in which β-TCP accounts for about 25wt%;

[0035] (4) The dense β-TCP / HA bioceramic was soaked in Tris-HCl buffer at a solid-to-liquid ratio of 10:1 for 28 days to obtain a superficially porous β-TCP / HA bioceramic with a pore size of 1-6 μm, and the soaking time The longer it is, the larger the aperture and vice versa.

Embodiment 3

[0037] A preparation method of a superficially porous calcium phosphate bioceramic material is realized by the following steps:

[0038] (1) ACP and HA were prepared by chemical precipitation method, and mixed according to ACP:HA ratio of 1:1 to obtain ω ACP =50wt% ACP / HA composite powder;

[0039] (2) packing the ACP / HA composite powder after granulation into the molding die, and compacting under the condition that the pressure is 300MPa and the holding time is 3min;

[0040] (3) The compacted green body is heated to 1150°C, kept for 2 hours, and then naturally cooled in a sintering furnace to obtain dense β-TCP / HA bioceramics, in which β-TCP accounts for about 50wt%;

[0041] (4) The dense β-TCP / HA bioceramic was soaked in Tris-HCl buffer at a solid-to-liquid ratio of 10:1 for 28 days to obtain a superficially porous β-TCP / HA bioceramic with a pore size of 1-6 μm, and the soaking time The longer it is, the larger the aperture and vice versa.

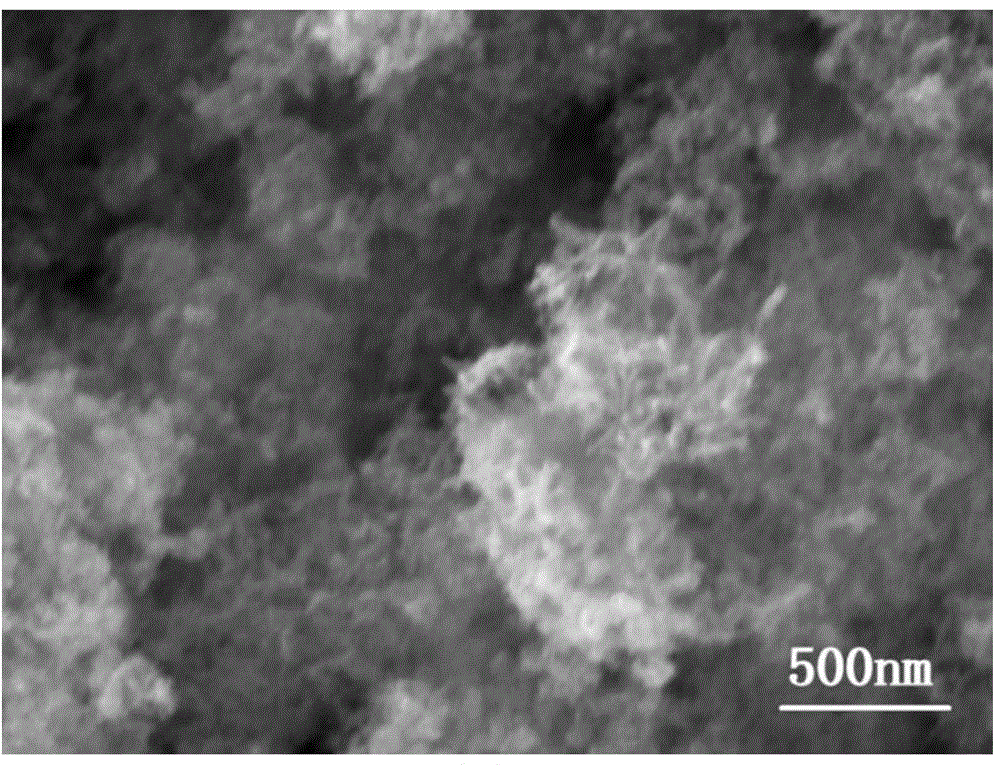

[0042] The scanning electron...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com