Diallyl phosphorus-containing bio-based diacid ester and its preparation method and use

A technology of bio-based diacid diallyl ester and bio-based diacid diglycidol, which is applied in the field of halogen-free flame retardants to achieve the effects of saving resources, improving compatibility, and good flame retardant properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

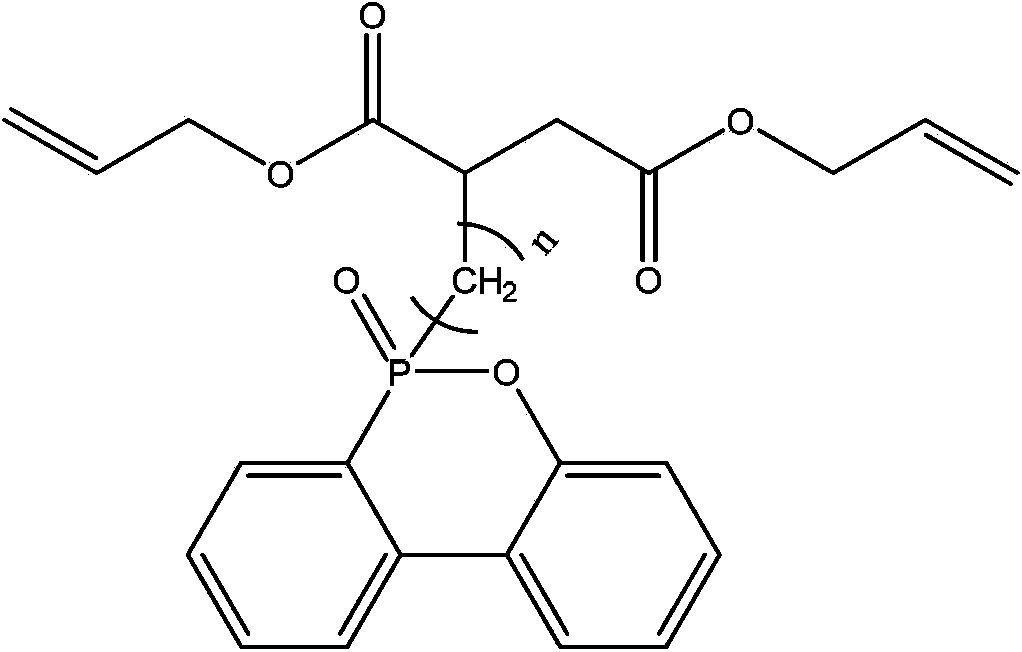

[0045] Embodiment 1 (preparation of phosphorous-containing itaconic acid)

[0046] 100g itaconic acid, 167g9,10-dihydro-9-oxa-10-phosphaphenanthrene-10-oxide (DOPO), 300g toluene and 10g mass percent are 1% isopropanol solution of chloroplatinic acid ( 1% refers to the mass percentage of chloroplatinic acid), mixed evenly, reacted at 120°C for 12 hours, filtered, washed with acetone and dried to obtain phosphorus-containing itaconic acid, which is a phosphorus-containing bio-based diacid with the structure of formula II , where n=1.

[0047]

[0048] Formula II

Embodiment 2

[0049] Embodiment 2 (preparation of phosphorus-containing butenedioic acid)

[0050] 100g of maleic acid or fumaric acid, 170g of 9,10-dihydro-9-oxa-10-phosphaphenanthrene-10-oxide (DOPO), 500g of xylene and 10g of 1% by mass Chloroplatinic acid isopropanol solution (1% refers to the mass percentage of chloroplatinic acid), mixed evenly, reacted at 130°C for 12 hours, filtered, washed with acetone, and dried to obtain phosphorus-containing butenedioic acid, namely A phosphorus-containing bio-based diacid with a structure of formula II, wherein n=0.

[0051]

[0052] Formula II

Embodiment 3

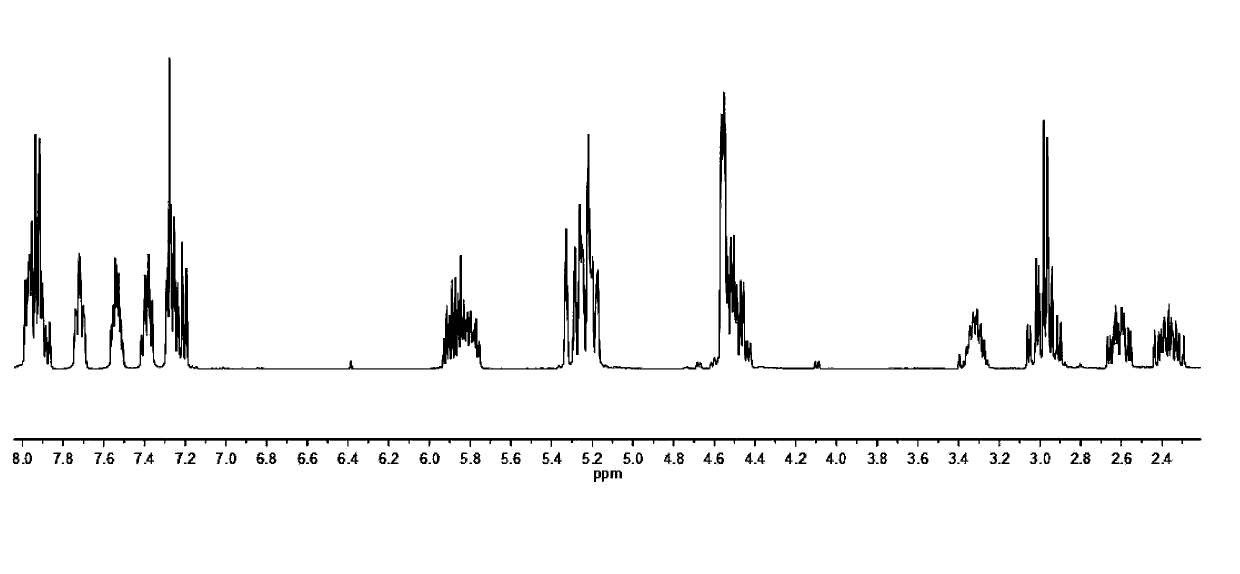

[0054] 100g of the phosphorus-containing itaconic acid prepared in Example 1, 900g of tetrahydrofuran, 400g of allyl chloride and 300g of potassium carbonate were reacted at 40°C for 72 hours, filtered, washed with water, and evaporated under reduced pressure to remove the solvent and water to obtain the phosphorus-containing coating Diallyl conate (structure shown in formula I, n=1). The phosphorus-containing diallyl itaconate 1 H NMR spectrum as figure 1 as shown, 1 The appearance of 5.25ppm and 5.8ppm in the H NMR spectrum represents the H on the allyl double bond, and other peaks are consistent with the H proton shift of phosphorus-containing diallyl itaconate, proving that the obtained substance is phosphorus-containing Diallyl itaconate (structure shown in formula I, n=1).

[0055]

[0056] Formula I

PUM

| Property | Measurement | Unit |

|---|---|---|

| Glass transition temperature | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

| Glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com