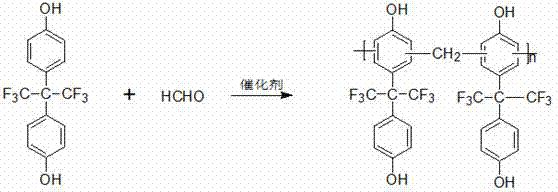

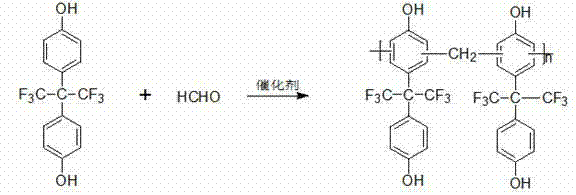

Preparation method of 4,4'-(hexafluoroisopropylidene)diphenol (Bisphenol AF) phenolic resin

A technology for phenolic resin and bisphenol, which is applied in the field of preparation of bisphenol AF phenolic resin, can solve the problems of difficult control of aldehyde-phenol ratio, lack of production technology, troublesome operation of the step-by-step aldehyde addition method, etc. high yield effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

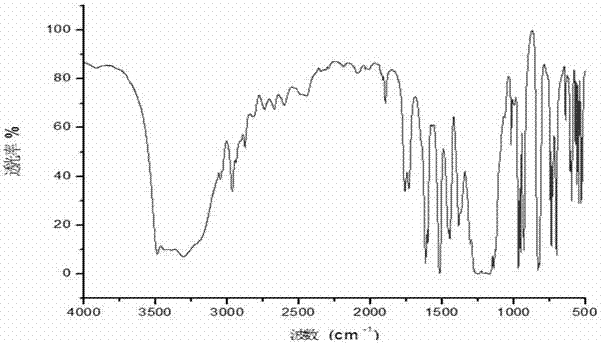

[0019] Add 16.8g (0.05mol) of bisphenol AF and 20ml of n-butanol into the four-neck flask. Set at 80°C and start heating and stirring until the bisphenol AF is completely dissolved. After cooling to room temperature, add 3.78g of formaldehyde solution with a mass concentration of 37% (containing 0.05mol of formaldehyde) and 2.0g of catalyst oxalic acid. The reflux reaction was carried out at 100°C for 6 hours, and then the solvent and water were removed by distillation under reduced pressure. The obtained product was washed with boiling water three times, and then distilled under reduced pressure again. Finally, after vacuum drying at 70° C. for 48 hours, an off-white solid was obtained with a weight of 16.73 g and a yield of 99.6%. The product was subjected to infrared spectrum analysis (see figure 2 ), the results showed that the off-white solid of the obtained product was bisphenol AF phenolic resin.

Embodiment 2-15

[0020] Example 2-15: (bisphenol AF: formaldehyde (molar ratio) = 1:1, reaction temperature T = 100°C)

[0021] Examples 2-15 Bisphenol AF phenolic resin was prepared according to the method of Example 1, but the amount of raw materials or catalysts and the polycondensation reaction temperature or reaction time were changed. The specific reaction conditions and yields are shown in Table 1.

[0022] Table 1 Example 2-15 reaction conditions and yield table

[0023] .

Embodiment 16-30

[0024] Example 16-30: (formaldehyde (molar ratio)=1:1, reaction temperature T=95°C)

[0025] Examples 16-30 Bisphenol AF phenolic resin was prepared according to the method of Example 1, but the amount of raw materials or catalysts and the polycondensation reaction temperature or reaction time were changed. The specific reaction conditions and yields are shown in Table 2.

[0026] Table 2 embodiment 16-30 reaction condition and productive rate table

[0027] .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com