Non-contact direct-current induction electrospray ionization device and method

An electrospray ionization, DC induction technology, applied in ion source/gun, parts of particle separator tube, preparation of test samples, etc., can solve the problem of low NSI analysis throughput, difficulty in array analysis, and difficulty in electrical contact and other problems, to achieve the effect of saving sample consumption, improving detection throughput, and facilitating manufacturing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

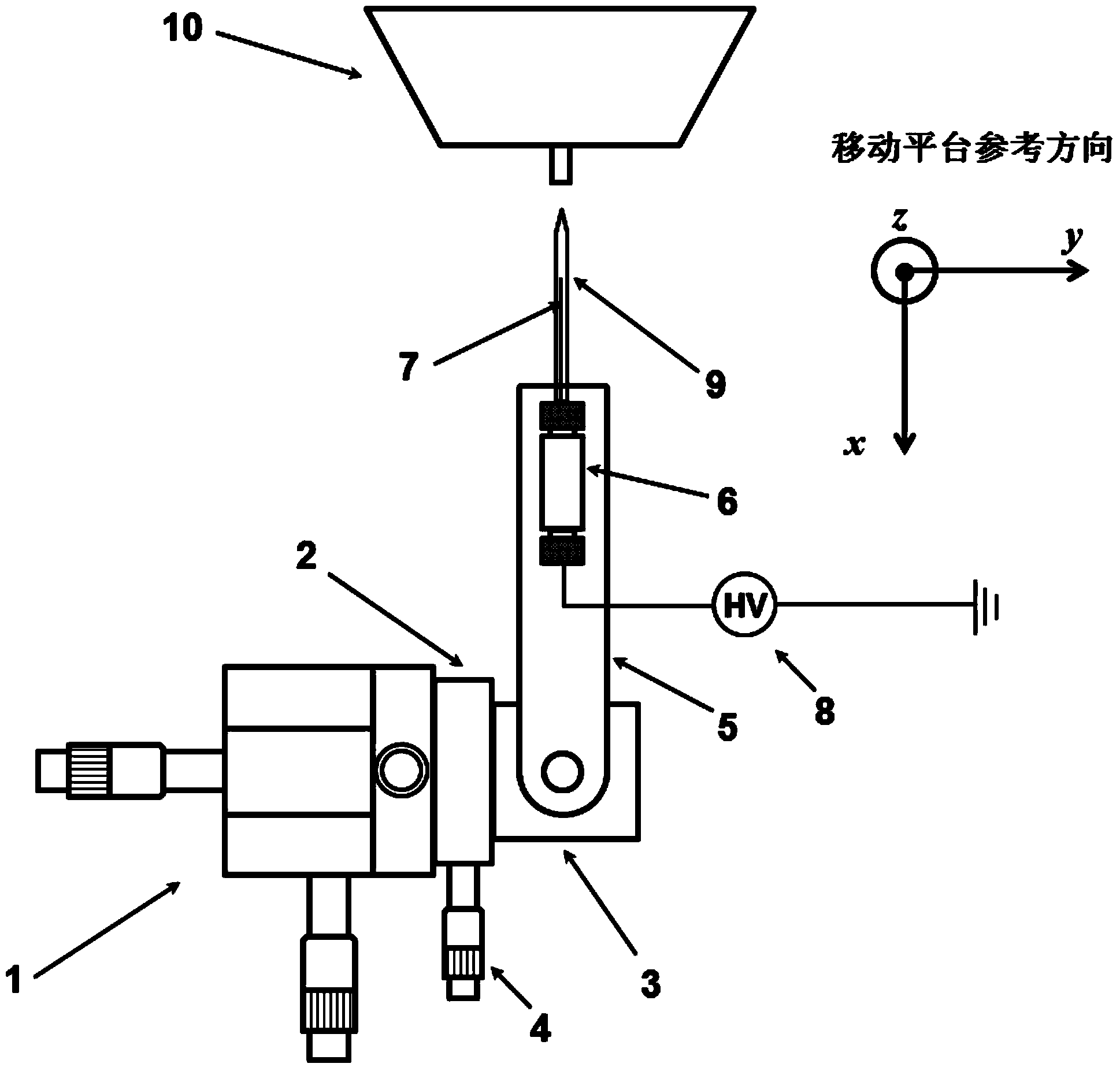

[0054] Embodiment 1, non-contact DC induction nano-liter electrospray ionization device

[0055] Such as figure 1 As shown, the non-contact DC induction nano-liter electrospray ionization device provided by the present invention includes a four-dimensional mobile platform, which includes a three-dimensional mobile platform I1 and is connected with the workbench of the three-dimensional mobile platform I1 The block I2 is connected to the block II3, and the block I2 is connected to a handle 4, and the handle 4 can control the rotation of the block II3 around the y-axis. A cantilever I5 is connected to the upper end face of the block II3, the cantilever I5 can rotate in the xy plane, and it is made of polytetrafluoroethylene. A two-way joint 6 is fixed on the upper surface of the cantilever I5; Wherein, the nano-liter electrospray nozzle 9 is fixed on one end of the two-way joint 6, and the electrode 7 extends into the interior of the nano-liter electrospray nozzle 9, and a dis...

Embodiment 2

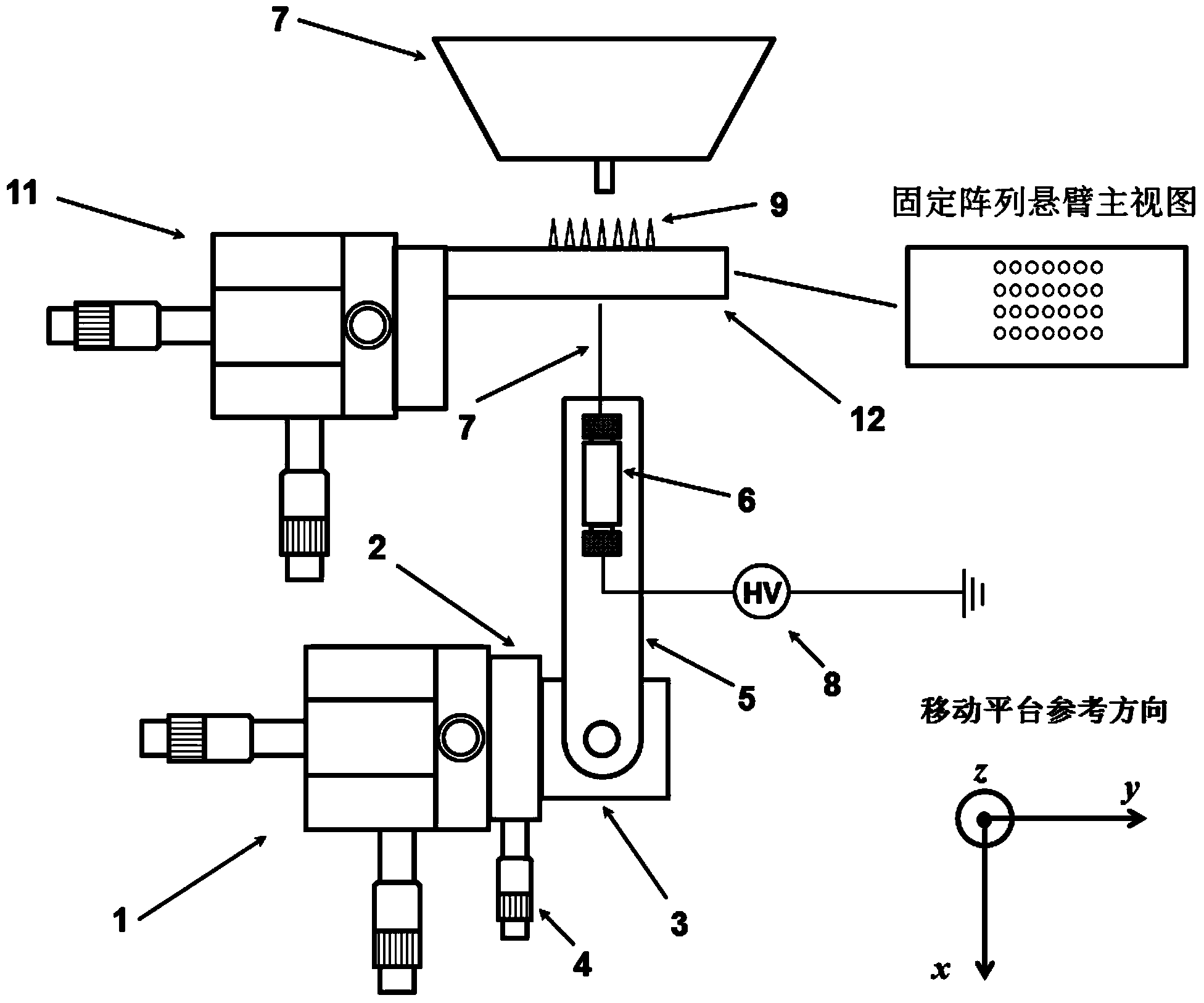

[0065] Example 2. Non-contact DC induction nano-liter electrospray ionization device for array analysis

[0066] Such as figure 2 As shown, the non-contact DC induction nano-liter electrospray ionization device for array analysis provided by the present invention includes a four-dimensional mobile platform, which includes a three-dimensional mobile platform I1 and a working with the three-dimensional mobile platform I1 The block I2 connected to the platform, the block I2 is connected to the block II3, and the block I2 is connected to a rotary handle 4, and the rotary handle 4 can control the rotation of the block II3 around the y-axis. A cantilever I5 is connected to the upper end face of the block II3, the cantilever I5 can rotate in the xy plane, and it is made of polytetrafluoroethylene. A two-way joint 6 is fixed on the upper surface of the cantilever I5; The electrospray ionization device of this embodiment also includes a three-dimensional mobile platform II11, the wo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The inside diameter of | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com